Anti-acceleration optical fiber hydrophone probe device

An optical fiber hydrophone and acceleration technology, which is used in measurement devices, instruments, and ultrasonic/sonic/infrasonic measurements, etc., can solve the problems of complex structure and excessive volume, achieve small size, increase safety and reliability, and facilitate array integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

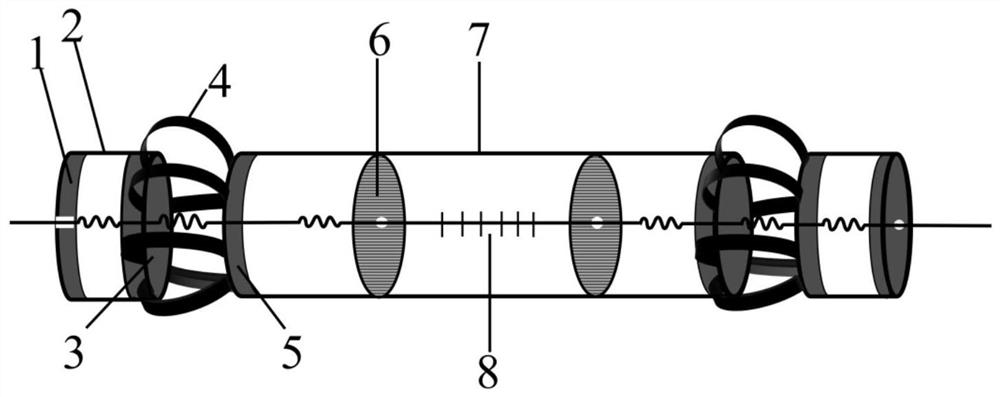

[0021] The purpose of the present invention is to utilize the advantages of optical fiber hydrophones, aiming at the limitations of existing optical fiber hydrophone probe structures, to propose a novel anti-acceleration optical fiber hydrophone probe structure device, effectively combining the advantages of the prior art, and solving the traditional The single advantage of the optical fiber hydrophone probe provides a strong guarantee for the sound pressure detection technology of the optical fiber hydrophone.

[0022] The hydrophone using the passive fiber grating or the active fiber grating as the sensing probe has a relatively simple structure, is more convenient for array integration, and has superior performance compared with the optical interference type hydrophone. The bare fiber grating is not sensitive to the sound pressure signal. In the structure of the hydrophone probe, the sound pressure sensitive elements such as the metal structure and the elastic diaphragm are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap