Astringent taste evaluation method based on beer components

An evaluation method and technology of astringency, which is applied in the field of astringency evaluation based on beer components, can solve problems such as poor correspondence of astringency, no consideration of astringent substances, cumbersome steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of standard curve: prepare standard solutions with different concentration gradients with 0.1mg / mL standard protein BSA solution, the volume of the standard solution for gradient dilution is 0.5ml; add 5mL of Coomassie Brilliant Blue staining solution, mix the liquid with a vortex shaker, Let stand for 5min; detect the absorbance of the liquid at 595nm. Take the protein mass (mg) as the ordinate, and take the measured absorbance as the abscissa, draw a standard curve, and establish a regression equation Y=0.0028x+0.2794, R 2 >0.99, calculated sample OD value=0.0028ⅹprotein concentration+0.2794.

[0031]2) Take 0.15 mL of the sample, add 0.35 mL of 0.15 mol / L NaCl solution to make the mixed liquid volume 0.5 mL; add 5 mL of Coomassie Brilliant Blue staining solution, mix the liquid with a vortex oscillator, and let it stand for 5 minutes. The absorbance of the liquid was measured at 595 nm. The sample protein concentration was converted by the standard c...

Embodiment

[0033] Sensory Evaluation Method

[0034] 1) Tasting group: 7-8 fixed staff (including more than 4 national-level sommeliers), light food, tasting between 14:00-17:30 in the afternoon;

[0035] 2) Sample preparation: all samples are kept at a constant temperature of 15 degrees;

[0036] 3) Sensory description of astringency: astringency focuses on tongue friction and tongue friction after drinking;

[0037] 4) Astringent evaluation process: Sip the sample, the liquid flows in the mouth for more than 10 seconds, and feel the friction intensity of the tongue surface during the flow of the liquid in the mouth and after swallowing; rinse your mouth with water between samples, and stay between samples for 1 minute ;

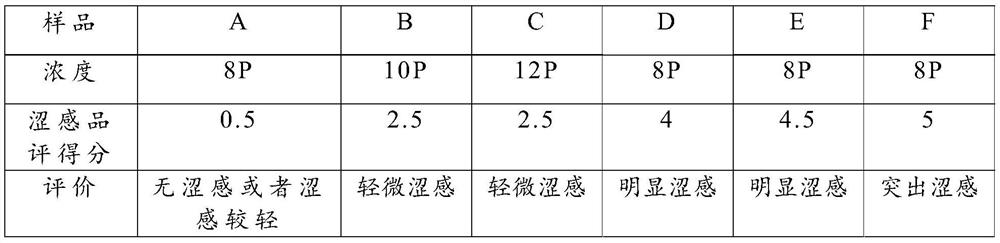

[0038] 5) Scoring principles for astringency: 0-1: no astringency or mild astringency; 1-3: slight astringency; 3-5: obvious astringency, ≥5: prominent astringency. The specific results are shown in Table 1.

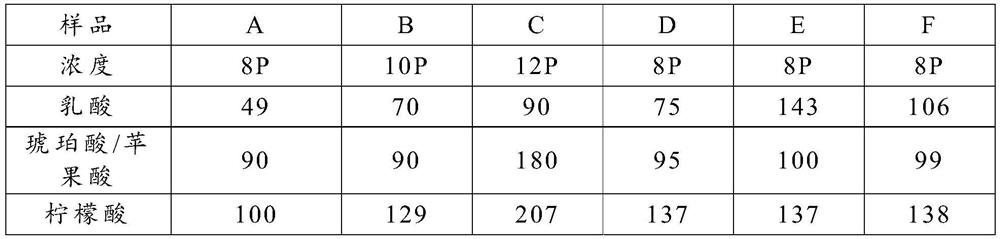

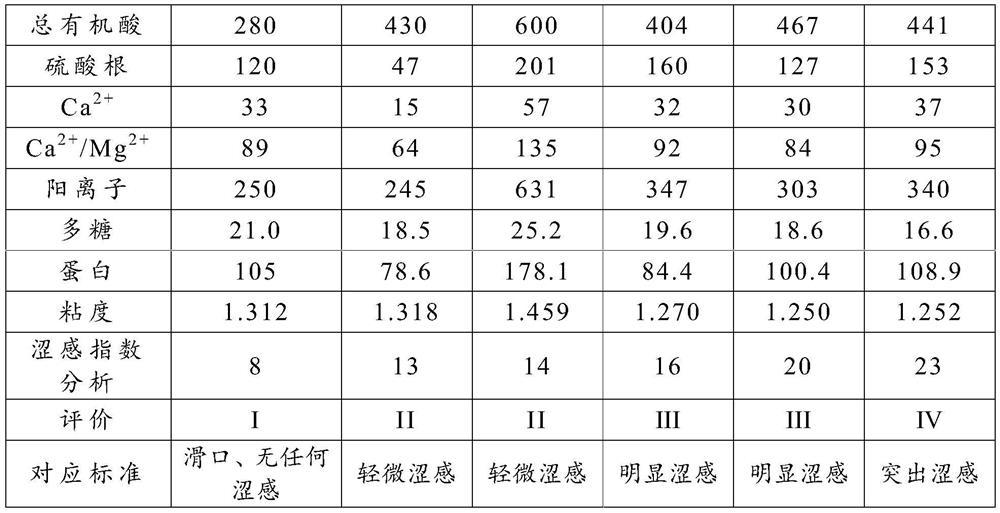

[0039] Table 1 Analysis of sensory evaluation methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com