Physalis alkekengi soy sauce and preparation process thereof

A preparation process, the technology of red mushroom niang, applied in the field of red mushroom niang soy sauce and its preparation, can solve the problems affecting the taste of soy sauce, rancidity, etc., and achieve the effect of rich and mellow sauce, clear shape, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

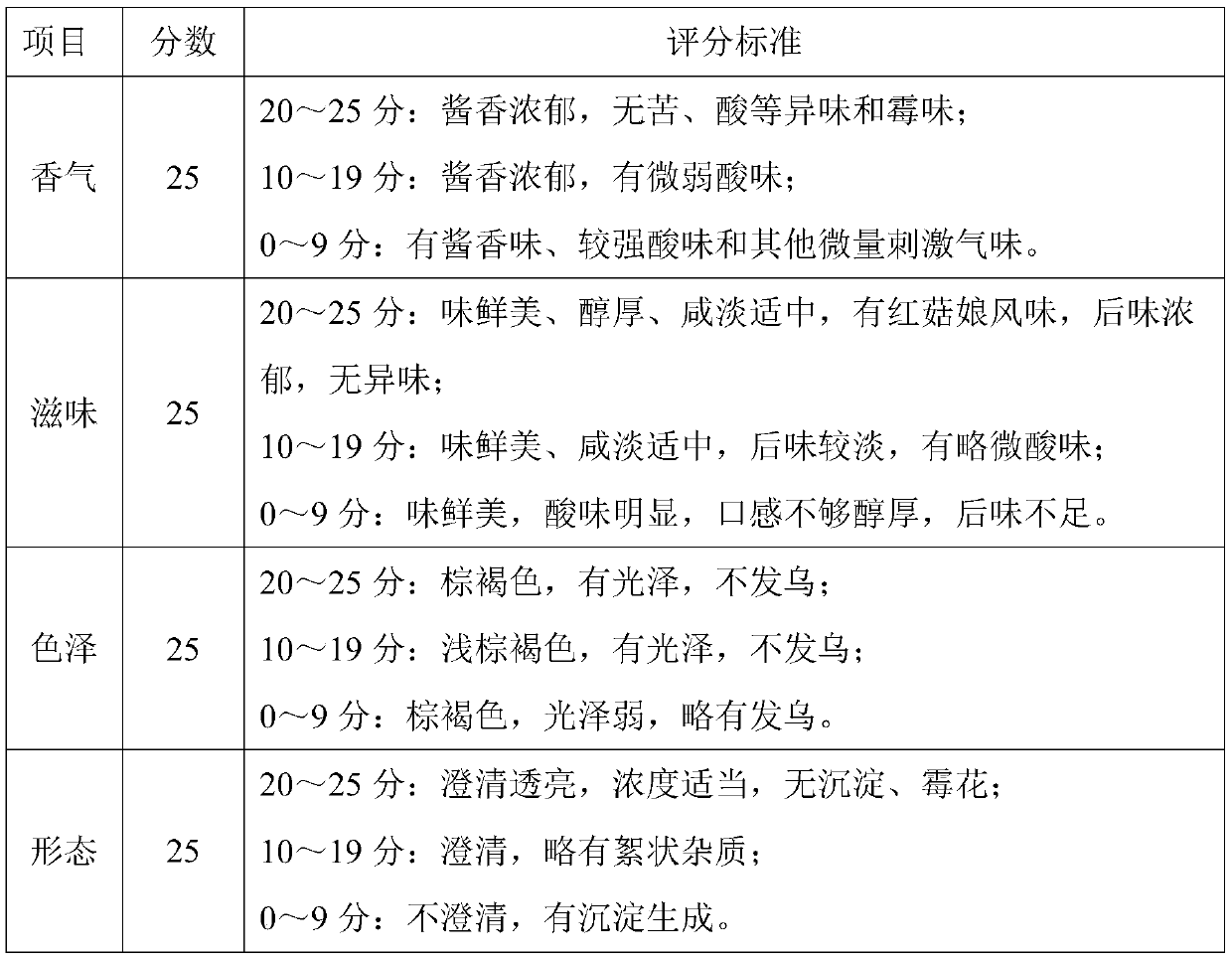

Examples

preparation example Construction

[0119] In a preferred embodiment, the preparation method of the aroma-enhancing high-salt-tolerant yeast liquid of the present invention comprises the following steps:

[0120] 1.5-3% glucose, 0.5-2% peptone, 0.4-0.8% yeast extract and 15-20% salt are cultured at 30-32° C. for 45-50 hours to obtain aroma-enhancing high-salt-tolerant yeast liquid.

[0121] In a preferred embodiment, the preparation method of the aroma-enhancing high-salt-tolerant yeast liquid of the present invention comprises the following steps:

[0122] Cultivate 2% glucose, 1% peptone, 0.5% yeast extract and 18% salt at 30-32°C for 45-50 hours to obtain an aroma-enhancing high-salt-tolerant yeast liquid.

[0123] In a preferred embodiment, in step (4) leaching of the present invention, the salt in the additive is configured as 3-5wt% brine at a temperature of 55-65° C. Soak for 18-24 hours at ~55°C to obtain moromi.

[0124] In a preferred embodiment, the moromi of the present invention is left standing a...

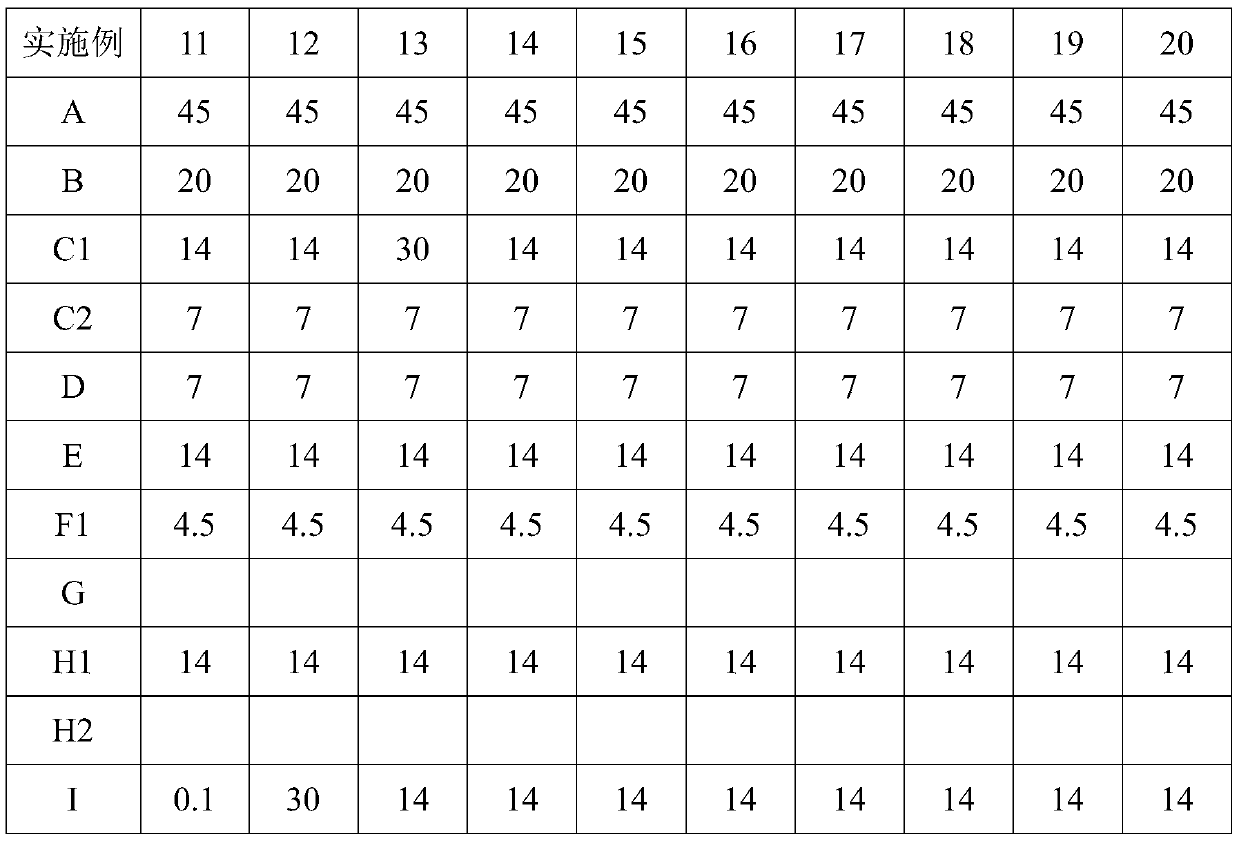

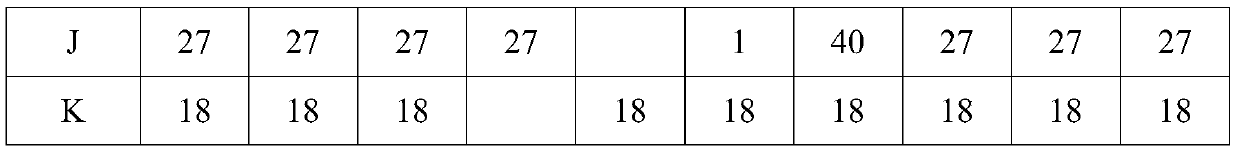

Embodiment 1~17

[0155] Embodiment 1~17 provides a kind of preparation method of red mushroom soy sauce, comprising the following steps:

[0156] (1) Raw material processing: Mix cereals and corn flour, dry steam at 0.2MPa, 85°C for 30min, add water at 75°C, stir for 15min, the water accounts for 60wt% of the total weight of cereals and cornflour, and then grind Mix the cereals into 70 meshes to obtain the primary mixture, add water at 55°C, the water accounts for 50wt% of the primary mixture, stir for 35min to obtain the mixture, steam the mixture at 120°C and 0.15MPa for 40min, Cooling down to 50°C to obtain koji material; beating extracts of Russula chinensis fruit, raspberry, hawthorn leaf and eggplant to obtain slurry;

[0157] (2) Koji making by inoculation: Aspergillus oryzae and Aspergillus niger were cultured at 28° C. for 3 days to prepare koji, inoculated onto the mixture of koji material and slurry, and koji-making was performed. 0.3wt%, Aspergillus niger accounts for 0.1% of the ...

Embodiment 18

[0163] Embodiment 18 provides a kind of preparation method of russula soy sauce, its specific implementation method is the same as that of embodiment 6, the difference is that the step (3) uses low-salt high-temperature fermentation in the early stage of fermentation, and high-salt low-temperature fermentation in the later stage; In the above-mentioned low-salt high-temperature fermentation, the finished koji was stirred with 60°C salt water, the concentration of the salt water was 14°Bé, and the salt water accounted for 90% by weight of the finished koji, and the fermentation was sealed. First, it was fermented at 45°C for 5 days, and then fermented at 50°C for 3 days. Finally, it was fermented at 45°C for 7 days; in the high-salt low-temperature fermentation, the product temperature dropped to 34°C, and the alkaline water accounting for 65wt% of the koji weight was slowly poured down, the temperature was 30°C, and the alkali content in the alkaline water was 10wt%. And add sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com