Grain pile condensation prediction method based on support vector regression (SVR)

A support vector regression and prediction method technology, applied in the field of grain storage, can solve the problems of not being able to know the grain condensation, the specific location is difficult, and the moisture content requires a lot of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

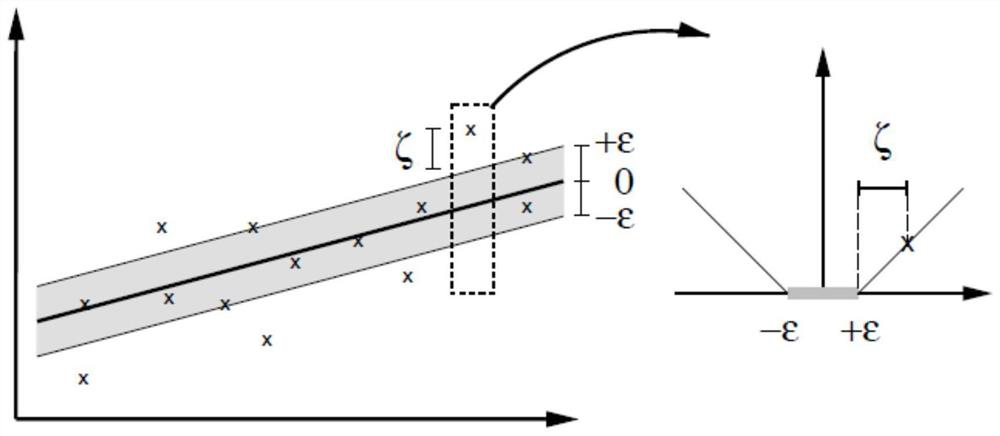

Method used

Image

Examples

Embodiment 1

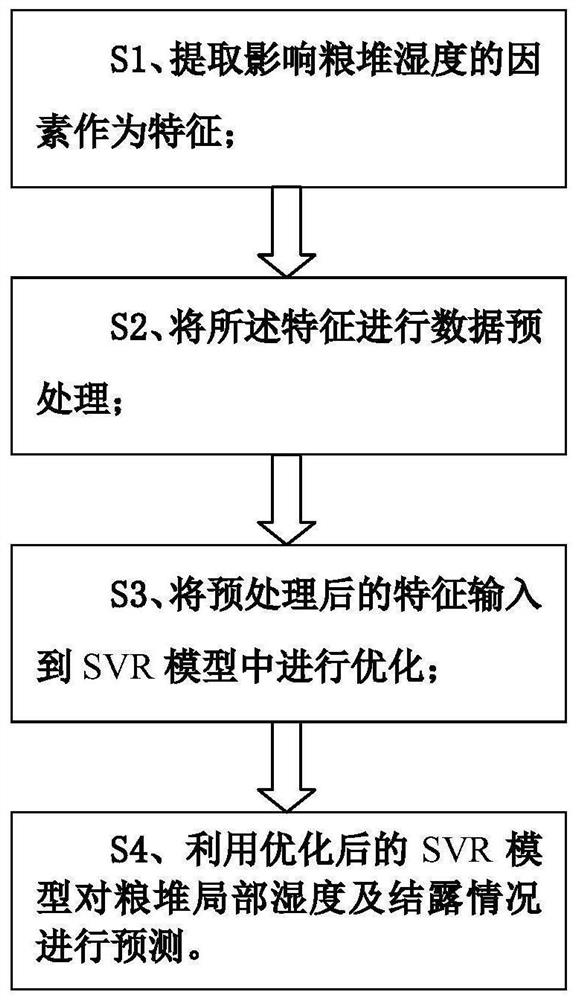

[0035] refer to figure 1 As shown, the present invention proposes a method for predicting dew condensation in grain piles based on support vector regression SVR, which specifically includes the following steps:

[0036] 1. Feature extraction:

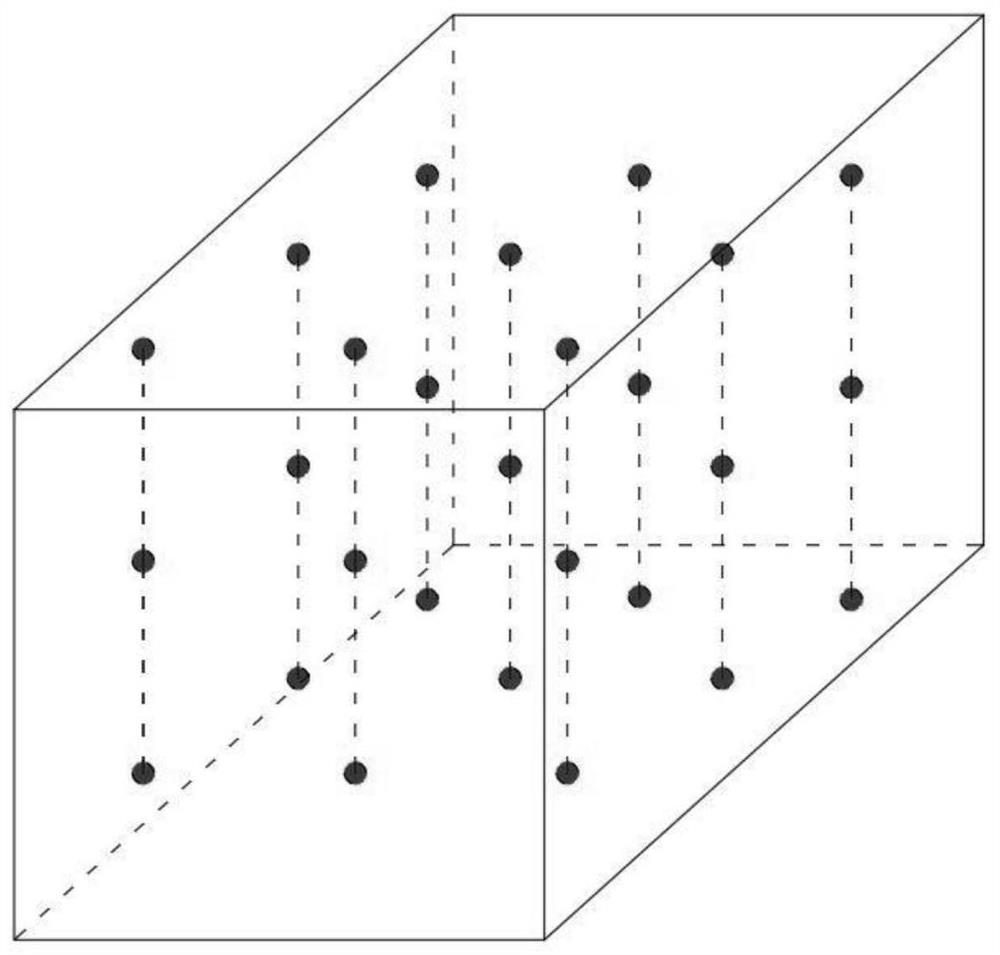

[0037] First of all, temperature and humidity sensors are arranged at different positions of the grain pile to regularly read the data factors affecting the humidity of the grain pile during the storage process; refer to figure 2 As shown in the figure, the black dots in the figure are the arrangement points of the temperature and humidity measuring sensors. The position and quantity of the arrangement points can be adjusted according to the position where the warehouse is prone to condensation and the size of the warehouse; Read and record temperature and humidity data. The data includes: grain temperature, grain moisture, and humidity in the grain pile at each position of the grain pile; then these data are preprocessed and classif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com