Preparation method of all-solid-state battery, and all-solid-state battery

An all-solid-state battery and solid-state electrolyte technology, applied in the manufacture of electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of insufficient contact between electrodes and electrolytes, difficulty in industrialized production, and large internal resistance of batteries, and avoid environmental dew point. restrictions, avoid the use of highly toxic solvents, and the effect of a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

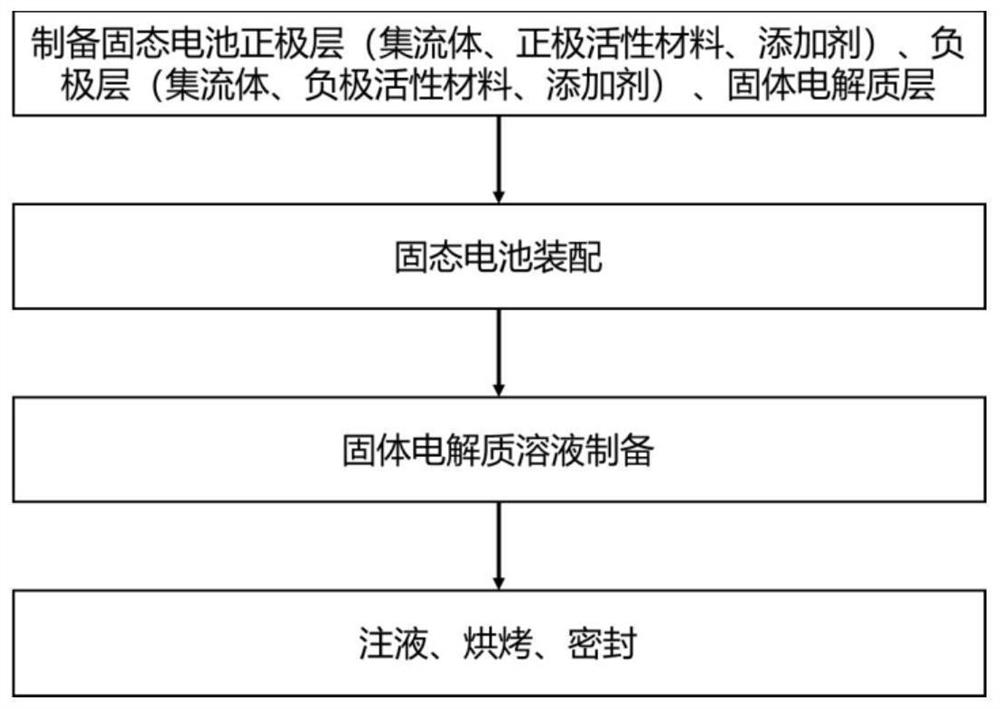

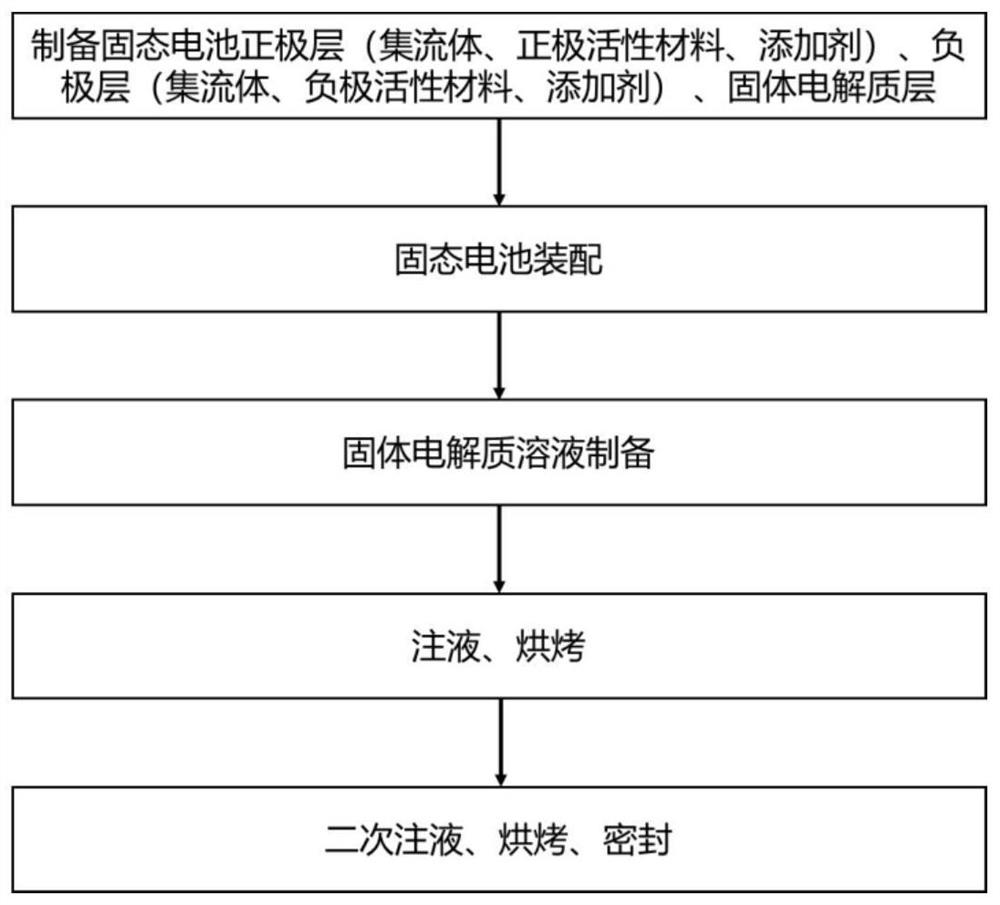

[0048] This embodiment provides a method for preparing an all-solid-state battery, such as figure 1 As shown, the preparation method specifically includes the following steps:

[0049] (Ⅰ) The positive electrode, negative electrode and 75Li 2 S-25P 2 S 5 Assembled into an all-solid-state battery assembly;

[0050] (II) configure the second solid electrolyte solution under nitrogen atmosphere, the second solid electrolyte solution includes Li 6 P.S. 5 Cl and ethanol, the mass fraction of ethanol is 70%, adopt the mode of vacuum liquid injection to inject the second solid electrolyte solution into the all-solid-state battery assembly, the vacuum degree of vacuum injection liquid is 70kPa, inject the second solid electrolyte solution after 100 ℃ Under vacuum drying;

[0051] (Ⅲ) Sealing after drying to obtain an all-solid-state battery.

Embodiment 2

[0053] This embodiment provides a method for preparing an all-solid-state battery, such as figure 1 As shown, the preparation method specifically includes the following steps:

[0054] (I) The positive electrode, negative electrode and Li 10 GeP 2 S 12 Assembled into an all-solid-state battery assembly;

[0055] (II) configure the second solid electrolyte solution under nitrogen atmosphere, the second solid electrolyte solution includes Li 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 and methanol, the mass fraction of methanol is 60%, and the second solid electrolyte solution is injected into the all-solid-state battery assembly by means of vacuum injection, and the vacuum degree of vacuum injection is 40kPa; after injecting the second solid electrolyte solution, at 50 ° C carry out vacuum drying;

[0056] (Ⅲ) Sealing after drying to obtain an all-solid-state battery.

Embodiment 3

[0058] This embodiment provides a method for preparing an all-solid-state battery, such as figure 1 As shown, the preparation method specifically includes the following steps:

[0059] (I) Assemble the positive electrode, negative electrode and the first solid electrolyte into an all-solid battery assembly, and the first solid electrolyte is 75Li 2 S-25P 2 S 5 and Li 10 GeP 2 S 12 combination of 75Li 2 S-25P 2 S 5 and Li 10 GeP 2 S 12 The mass ratio is 1:1;

[0060] (II) configure the second solid electrolyte solution under nitrogen atmosphere, the second solid electrolyte solution includes Li 6 P.S. 5 Br and ethanol, the mass fraction of ethanol is 90%, and the second solid electrolyte solution is injected into the all-solid-state battery assembly by means of vacuum injection, and the vacuum degree of vacuum injection is 90kPa; Under vacuum drying;

[0061] (Ⅲ) Sealing after drying to obtain an all-solid-state battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com