Waste incineration fly ash high-temperature melting balling device and balling compatibility method

A technology of waste incineration fly ash, high temperature melting, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc. problems such as ball formation to achieve the effect of improving performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

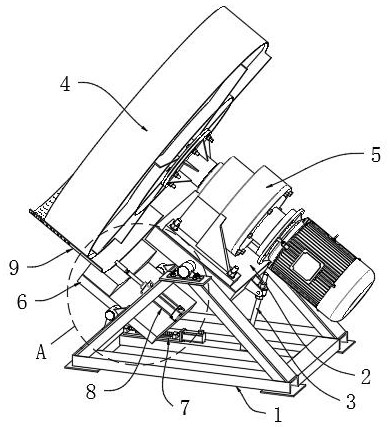

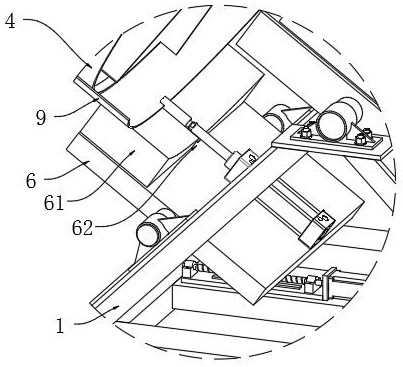

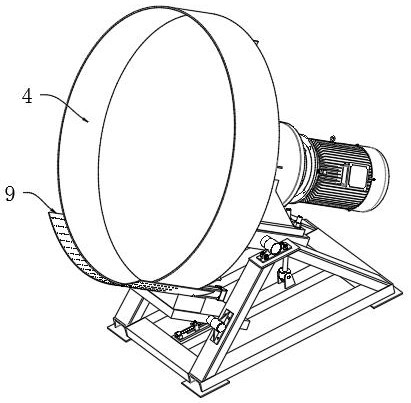

[0034] see Figure 1-3 , a device for high-temperature melting of waste incineration fly ash into balls provided by the present invention, comprising a trapezoidal support 1, a first base 2, a first turning mechanism 3, a granulation disc 4, and a rotating drive device 5, the first base 2 Rotately connected with the top of the trapezoidal support 1, the first base 2 is inclined, and the first turning mechanism 3 is connected between the lower end of the first base 2 and the bottom surface of the trapezoidal support 1 for adjusting the first base 2 and the trapezoidal support. The included angle of the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com