Movable soil vapor extraction treatment device

A gas-phase extraction and processing device technology, which is applied in the field of mobile soil gas-phase extraction and processing devices, can solve the problems of inconvenient transportation of gas-phase extraction devices, and achieve the effect of improving convenience and device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

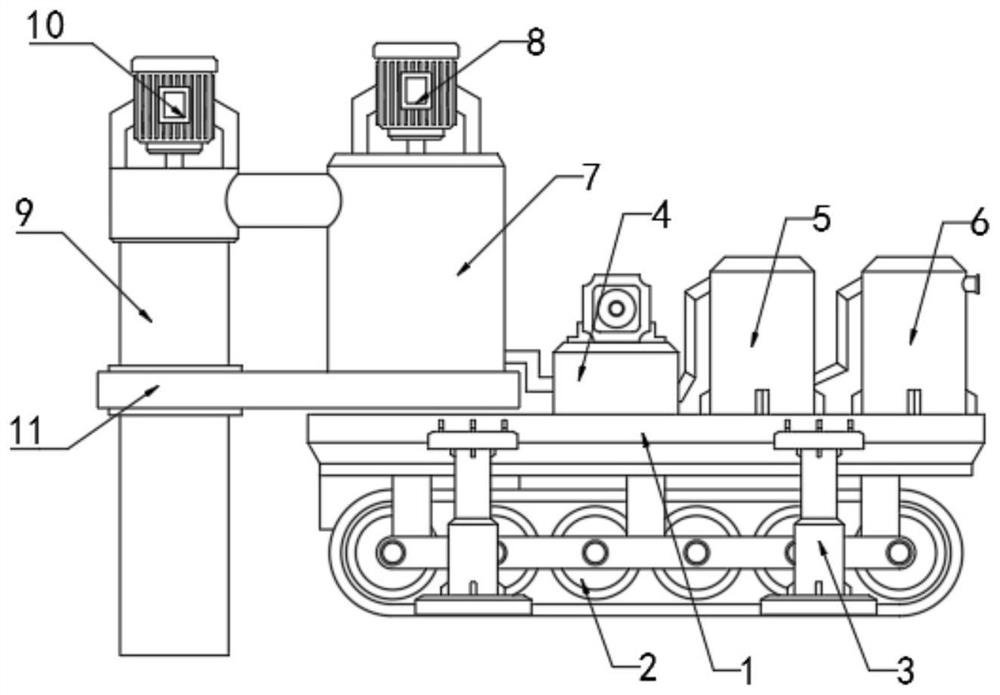

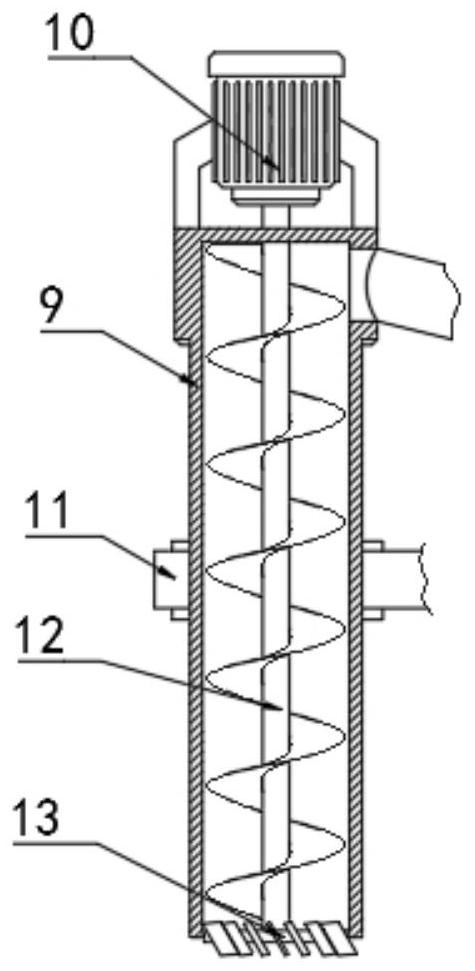

[0028] refer to Figure 1-6 , the present embodiment provides a mobile soil gas phase extraction treatment device, which includes: a car body 1, crawler belts 2 are provided on both sides of the car body 1, and the crawler belts 2 are controlled by the control system of the car body 1, and at the same time , the top of the car body 1 is fixedly connected with an air extraction system 4, a gas-liquid separation system 5, and an exhaust gas treatment system 6 in sequence from left to right, and between the air extraction system 4 and the gas-liquid separation system 5, the gas-liquid separation system 5 communicate with each other with the tail gas treatment system 6;

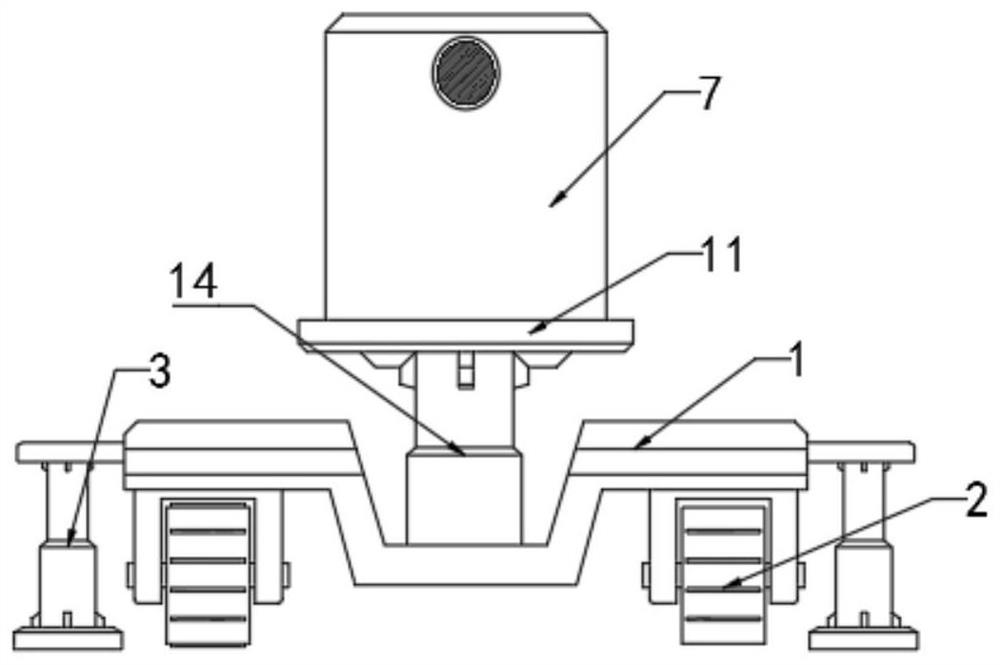

[0029] The air extraction system 4, the gas-liquid separation system 5 and the exhaust gas treatment system 6 adopt the existing technology, and the front end of the car body 1 is fixedly connected with a hydraulic cylinder 14, so that the bottom end of the hydraulic cylinder 14 is lower than the level of the car...

Embodiment 2

[0032] The only difference between this embodiment and Embodiment 1 is that the bottom end of the processing cylinder 7 is fixedly connected with an anti-seepage membrane mechanism to ensure that the gas in the air extraction system 4 will not flow back.

Embodiment 3

[0034] The only difference between this embodiment and Embodiment 1 is that, as Figure 1-3 As shown, the output end of the hydraulic cylinder 14 is fixedly connected to the connecting plate 11, and the top of the connecting plate 11 is fixedly connected to the processing cylinder 7. The lifting cylinder 9 and the processing cylinder 7 are transported synchronously to ensure a stable connection between the two, and at the same time ensure that the maximum downward transmission distance of the hydraulic cylinder 14 can reach the joint between the connecting plate 11 and the vehicle body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com