Metal workpiece welding position reinforcing device and implementation method thereof

A technology for reinforcing devices and metal workpieces, applied in metal processing, metal processing equipment, welding equipment, etc., can solve the problems of adaptive adjustment, poor overall practicability, inconvenient operation, etc., and achieve clamping effect and practicability Good, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] A method for implementing a reinforcement device at a welded part of a metal workpiece, comprising the following steps:

[0040] Step 1: First use a caliper to measure the diameter of the metal pipe to be welded, and remove the debris on the outer wall of the metal pipe to be welded. The purpose of measuring the diameter of the metal pipe to be welded is to confirm which clamping method is used and to remove the outer wall of the metal pipe to be welded The purpose of debris is to reduce the error and improve the clamping effect at the same time;

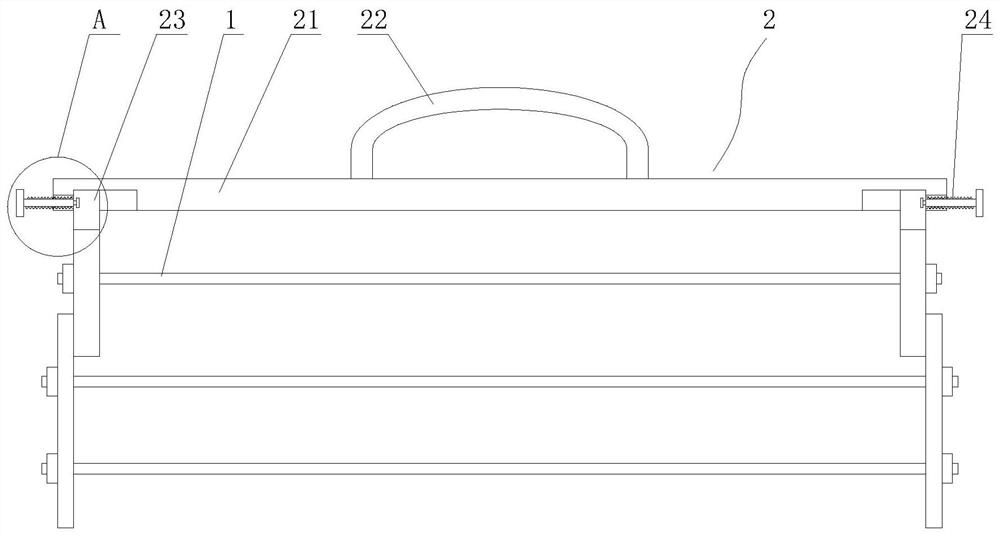

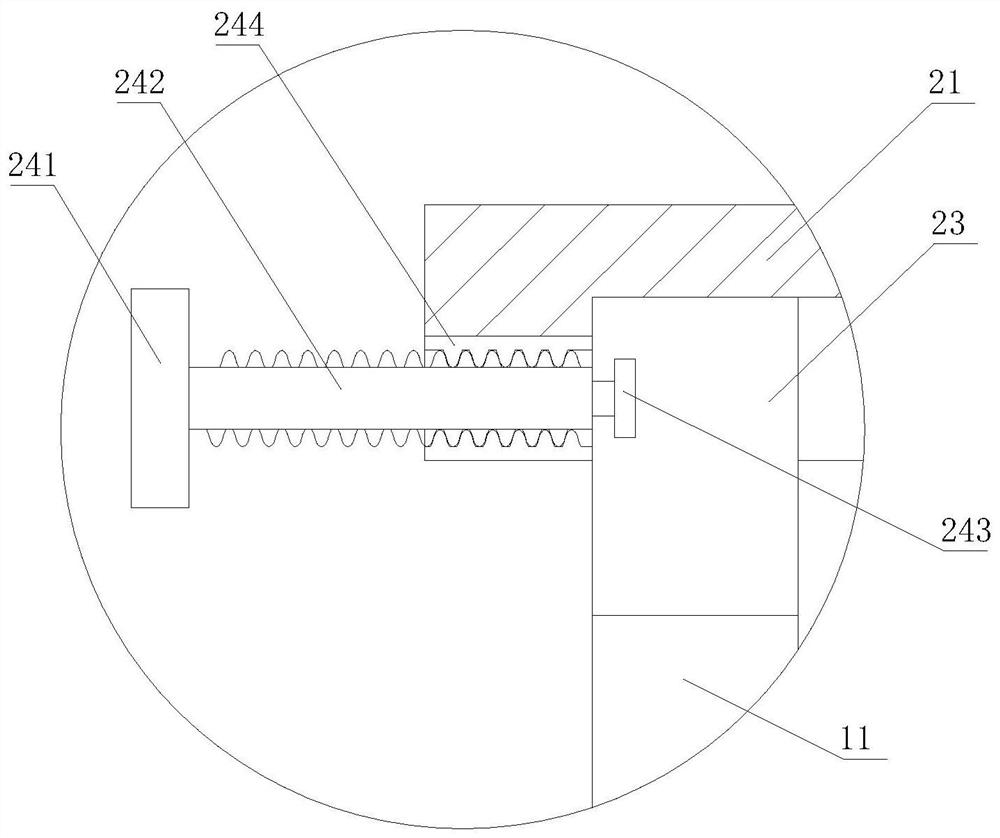

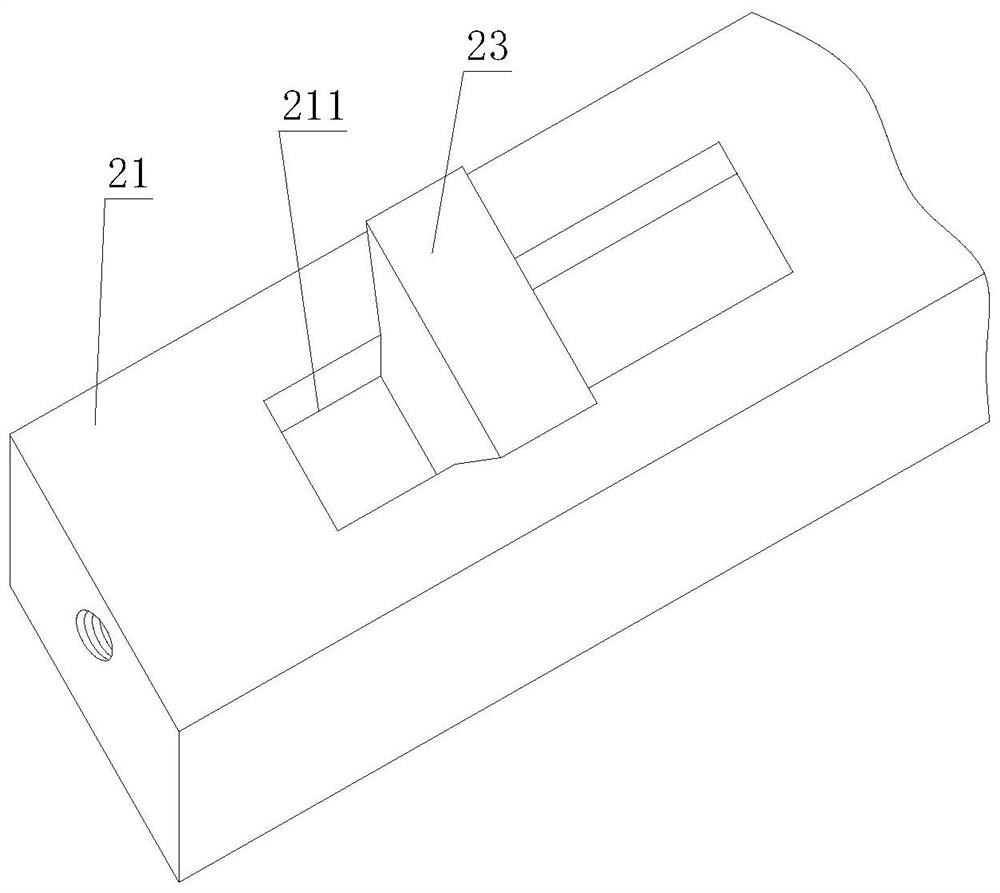

[0041] The second step: then move the entire reinforcement device to the top of the position to be welded, wherein the entire device can be easily moved by picking up the handle 22, wherein the welding end surface is located directly below the base plate 21, so as to ensure that the two groups of base splints 11, movable The distance between splint 12 and welding end face is the same;

[0042] Step 3: Then align the welding ...

Embodiment 2

[0046] A method for implementing a reinforcement device at a welded part of a metal workpiece, comprising the following steps:

[0047] Step 1: First use a caliper to measure the diameter of the metal pipe to be welded, and remove the debris on the outer wall of the metal pipe to be welded. The purpose of measuring the diameter of the metal pipe to be welded is to confirm which clamping method is used and to remove the outer wall of the metal pipe to be welded The purpose of debris is to reduce the error and improve the clamping effect at the same time;

[0048] The second step: then move the entire reinforcement device to the top of the position to be welded, wherein the entire device can be easily moved by picking up the handle 22, wherein the welding end surface is located directly below the base plate 21, so as to ensure that the two groups of base splints 11, movable The distance between splint 12 and welding end face is the same;

[0049] Step 3: Then align the welding ...

Embodiment 3

[0053] A method for implementing a reinforcement device at a welded part of a metal workpiece, comprising the following steps:

[0054] Step 1: First use a caliper to measure the diameter of the metal pipe to be welded, and remove the debris on the outer wall of the metal pipe to be welded. The purpose of measuring the diameter of the metal pipe to be welded is to confirm which clamping method is used and to remove the outer wall of the metal pipe to be welded The purpose of debris is to reduce the error and improve the clamping effect at the same time;

[0055] The second step: then move the entire reinforcement device to the top of the position to be welded, wherein the entire device can be easily moved by picking up the handle 22, wherein the welding end surface is located directly below the base plate 21, so as to ensure that the two groups of base splints 11, movable The distance between splint 12 and welding end face is the same;

[0056] Step 3: Then align the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com