Automatic keyboard elastic piece assembling machine

An automatic assembly machine and assembly mechanism technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high product defect rate, high labor intensity, and unsmooth feeding, so as to reduce the product defect rate and the degree of automation High and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

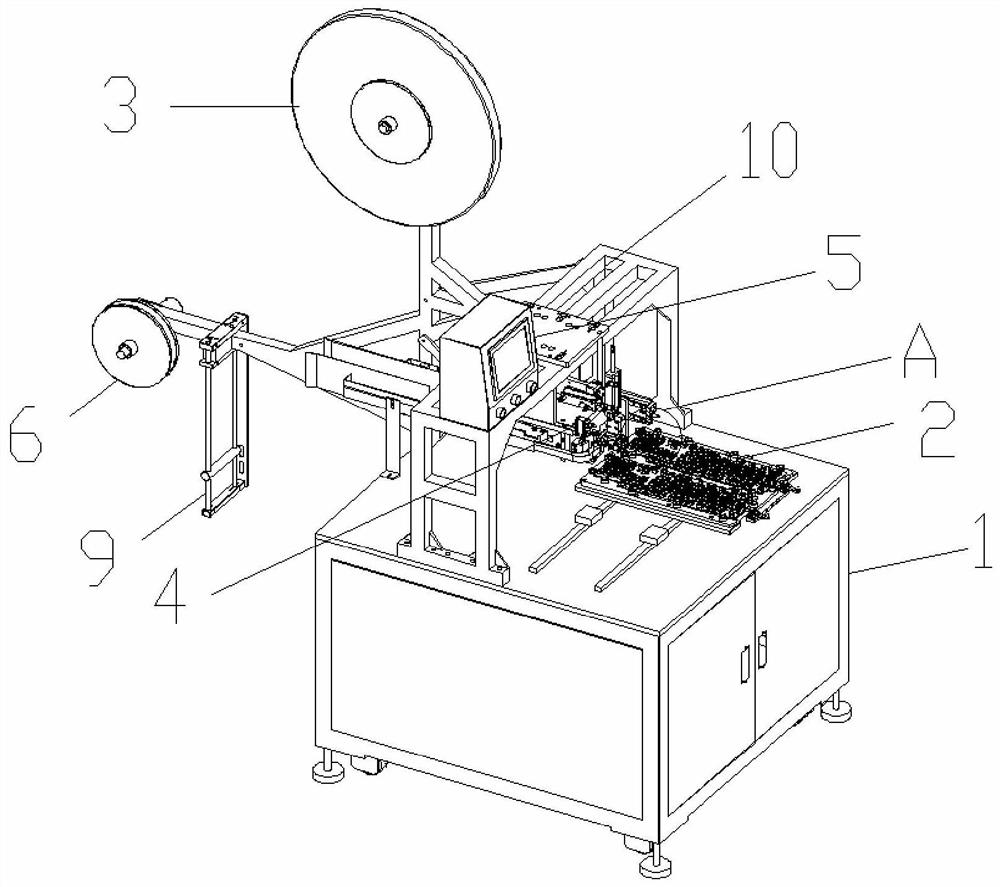

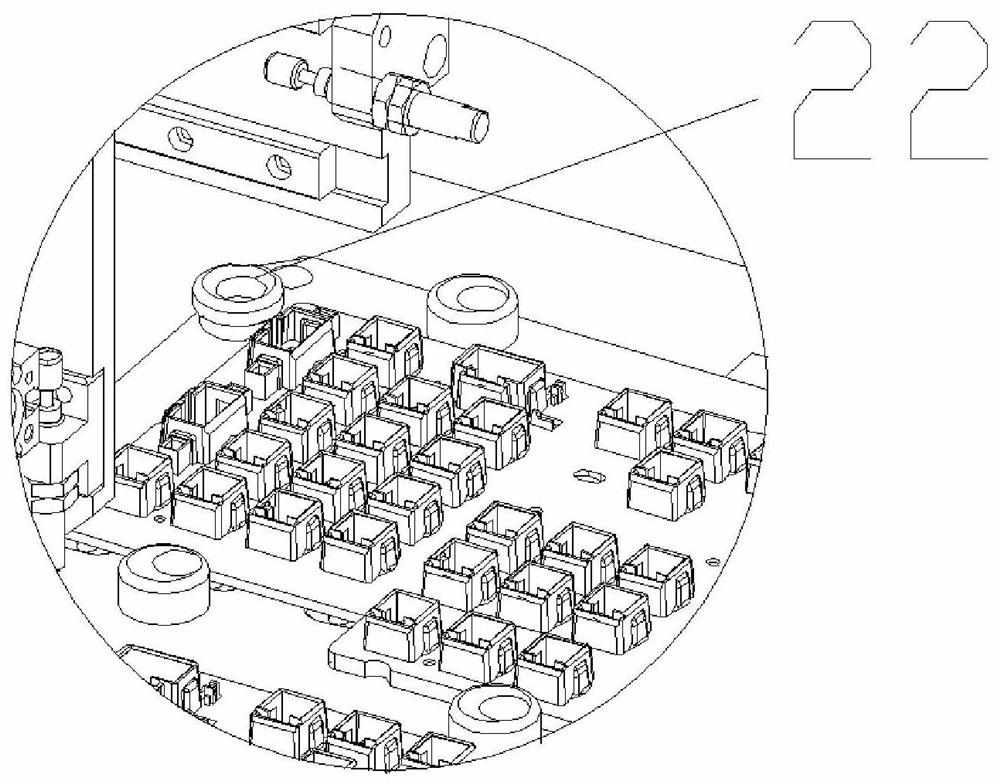

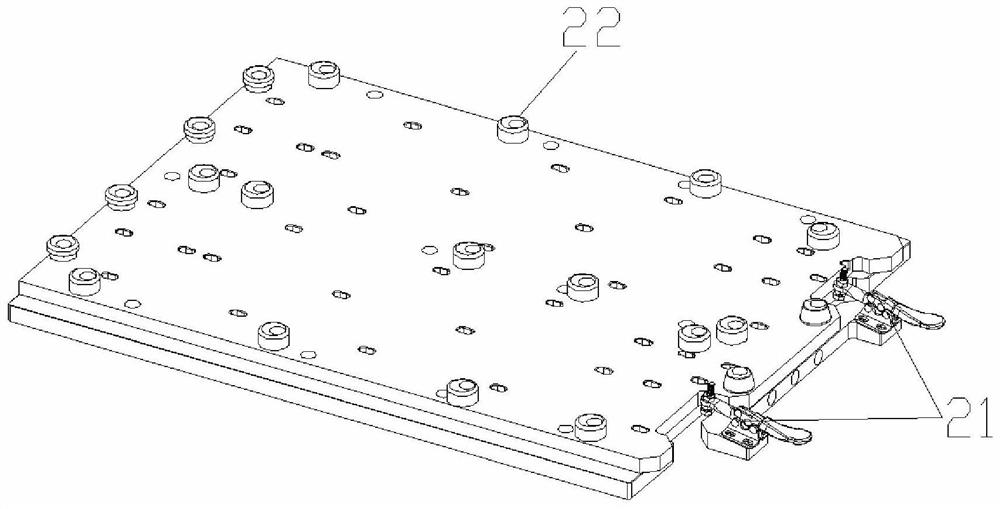

[0030] see Figure 1-14 As shown, the present invention relates to an automatic assembly machine for keyboard shrapnel, including a machine platform 1, on which a sliding platform carrier 2, a shrapnel material tape guide mechanism 3, a shrapnel assembly mechanism 4 and a paper tape recovery mechanism are arranged. , the slide table carrier 2 is arranged on the top surface of the machine table 1 and is used for middle plate positioning, a bracket 10 is arranged on the top of the slide table carrier 2, and a shrapnel assembly mechanism 4 is arranged on the top of the bracket 10, and the shrapnel assembly mechanism The rear of the 4 is provided with a shrapnel material belt guide mechanism 3, and the rear side of the shrapnel material belt guide mechanism 3 is provided with a paper tape recovery mechanism, and after the shrapnel material belt carried on the paper tape passes through the shrapnel material belt guide mechanism 3, The paper tape is recovered by the paper tape recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com