Optical lens high-precision polishing machine and its power transmission device

A technology of power transmission device and optical lens, which is applied in the direction of grinding drive device, grinding device, optical surface grinder, etc. It is convenient for production, processing and replacement, low precision requirements for assembly, and the effect of easy reclaiming and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

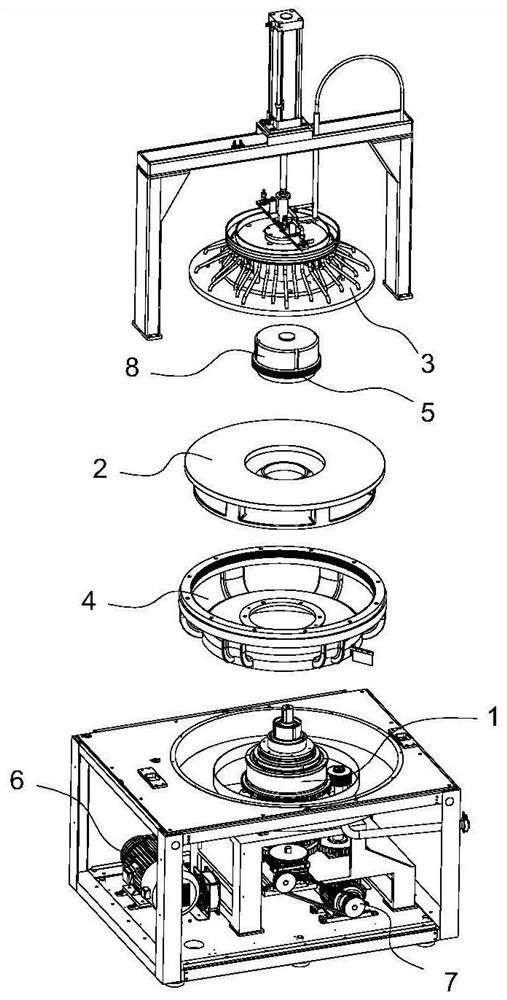

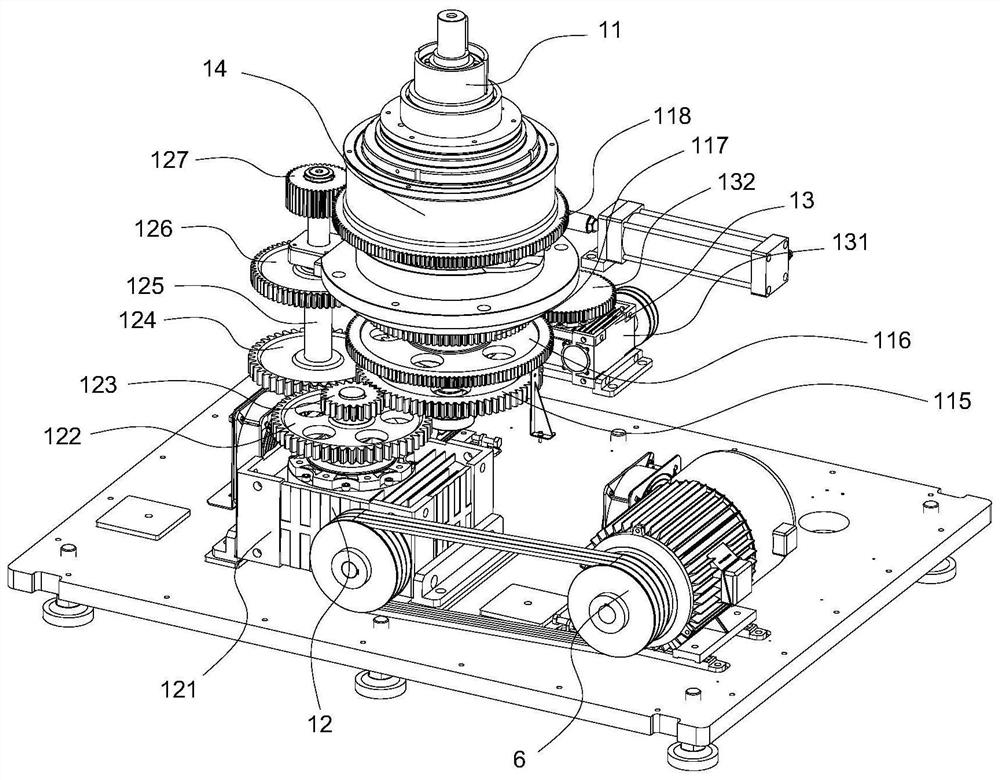

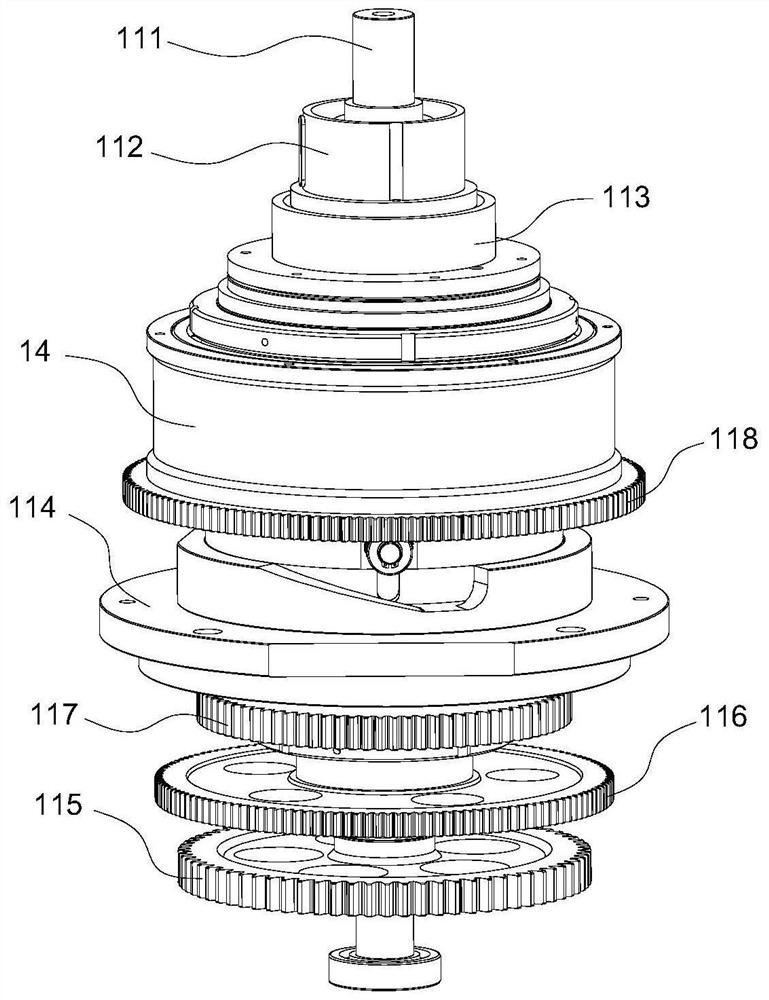

[0037] Such as figure 1As shown, a high-precision polishing machine for optical lenses, the processing equipment includes a frame and a power transmission device 1 installed on the frame, a lower grinding device 2, an upper grinding device 3, an upper grinding clutch device 8, a large ring gear device 4, A pinion gear arrangement 5 , a first motor 6 and a second motor 7 . The power transmission device 1 is arranged below the frame, and the upper grinding clutch device 8, the small ring gear device 5, the lower grinding device 2 and the large ring gear device 4 are installed on the power transmission device 1 sequentially from top to bottom. The upper grinding device 3 is vertically lifted and arranged on the top of the frame, and the upper grinding device 3 is positioned directly above the lower grinding device 2 . The bottom of the upper grinding device 3 cooperates with the upper grinding clutch device 8, and the upper grinding clutch device 8 controls the upper grinding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com