A kind of supergravity centrifugal 3D printed lunar soil concrete and its preparation method

A 3D printing and concrete technology, which is applied in the fields of aerospace, aviation, and space base station construction, can solve problems such as the impact of lunar soil concrete, and achieve the effect of CNC machining efficiency, structural force rationality, and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

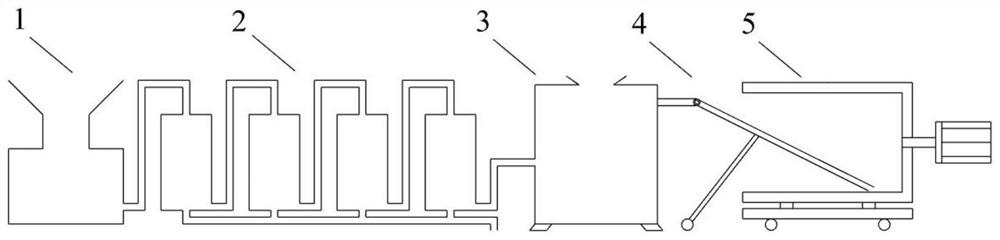

[0036] The supergravity centrifugal 3D printed lunar soil concrete and its preparation method provided by the present invention comprise the following steps:

[0037] (1) Screen and select lunar soil components suitable for 3D printing, and select suitable activators and lunar soil to configure lunar soil concrete.

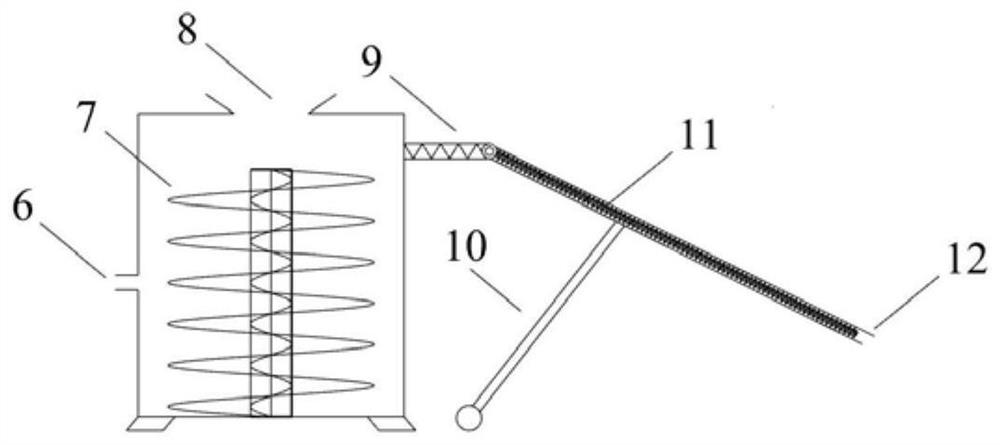

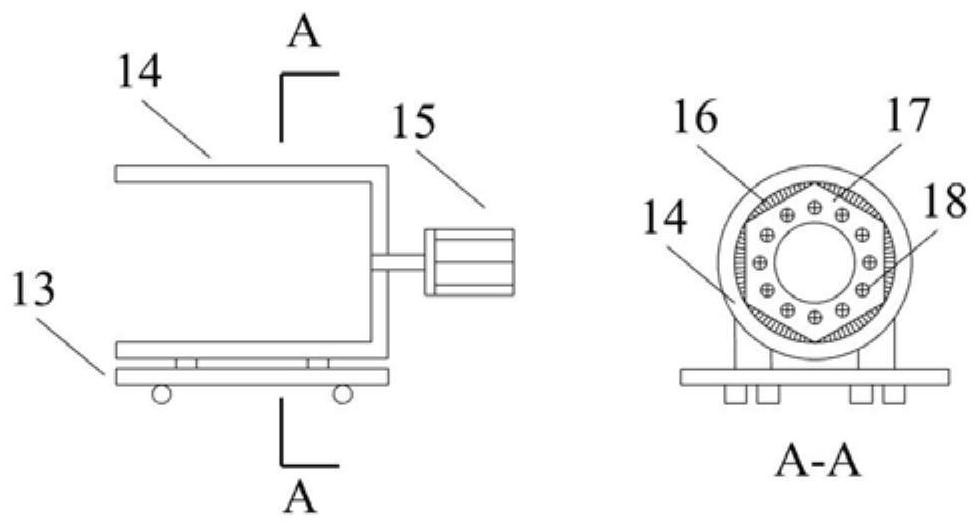

[0038] (2) Stir and mix the lunar soil concrete to a flow-plastic state, extrude and print it in the centrifugal cylinder, turn on the centrifugal cylinder to rotate at a uniform speed and horizontally position and move the printing to form a structure, so as to solve the difficulty that the lunar soil environment cannot be stacked and formed under weightlessness.

[0039](3) After the printing is completed, increase the centrifugal speed to a stable molding speed r 1 , select the centrifugation time to be 3-10 minutes according to the excitation method and composition ratio of the lunar soil;

[0040] (4) Enter the compaction stage of the 3D printed lunar soil c...

Embodiment 1

[0043] Embodiment 1 Preparation method of honeycomb hollow structure

[0044] 1. Put the mined lunar loam into the lunar soil import device 1, and obtain the raw materials of the lunar soil concrete through the refining and screening device 2: lunar soil highland sand 340, amorphous volcanic soil 60, JCS-1 soil 70, plain soil and sand 30 ;

[0045] 2. After calcining and cooling the raw materials of lunar soil concrete at high temperature in the batching and mixing device, mix them with water 150 (the material processing temperature is 1350-1450 degrees Celsius, and the hydration temperature is 20-80 degrees Celsius), sodium metasilicate 30, and sodium hydroxide 25. , fully stirred to form flow-plastic lunar soil concrete as printing ink (with the proportion of raw material similar to that of the earth, the concrete strength after excitation and mixing by the same process is greater than 35Mpa, and the fluidity is 183, which is suitable for 3D printing);

[0046] 3. Arrange t...

Embodiment 2

[0050] Embodiment 2 Capsule type hollow structure preparation method

[0051] 1. Put the mined lunar loam into the lunar soil import device 1, and obtain the raw materials of the lunar soil concrete through the refining and screening device 2: lunar soil highland soil sand 150, amorphous volcanic soil 160, JCS-1 soil 170, plain soil sand 20 ;

[0052] 2. After calcining and cooling the raw materials of lunar soil concrete at high temperature in the batching and mixing device, mix fully with water 190 (material processing temperature is 1350-1450 degrees Celsius, hydration temperature is 20-80 degrees Celsius) and polycarboxylate superplasticizer 1.5 Stir to form flow-plastic lunar soil concrete as printing ink (with the proportion of materials similar to the earth, the strength of the concrete mixed by the same process is greater than 45Mpa, and the fluidity is 179, which is suitable for 3D printing);

[0053] 3. According to the shape of the preset structure, a variable-diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com