Method for directly producing n-valeryl chloride and preparation method

A n-valeryl chloride, direct technology, applied in the field of direct production of n-valeryl chloride, can solve the problems of low efficiency of raw material processing and reaction, high energy consumption of production equipment operation, increase of production cost of n-valeryl chloride, etc., and achieve reduction of raw material use cost and The effect of energy consumption of processing equipment operation, reduction of production costs and environmental pollution, and improvement of comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

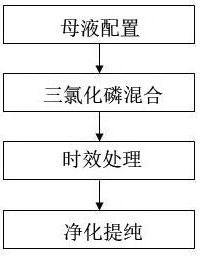

[0022] A method for directly producing n-valeryl chloride, comprising the following steps:

[0023] S1, mother liquor configuration, first select n-valeric acid with a water content of wei 20%, and add the selected n-valeric acid to the reactor, then reduce the pressure in the reactor to 0.02MPa, and after completing the air pressure adjustment, turn the reactor The internal temperature is raised to 45°C at a uniform speed within 120 seconds, and kept warm for 5 minutes;

[0024] S2, mix phosphorus trichloride, after completing step S1, adjust the temperature of n-valeric acid in the reactor to 45°C while keeping the pressure in the reactor constant, and then drop it into the n-valeric acid in the reactor at a constant speed within 10 minutes Add phosphorus trichloride, and when the phosphorus trichloride is added dropwise, the temperature of the n-valeric acid drops by no more than 1°C, and during the dropwise addition of the phosphorus trichloride, the mixed solution in the ...

Embodiment 2

[0034] A method for directly producing n-valeryl chloride, comprising the following steps:

[0035] S1, mother liquor configuration, firstly select n-valeric acid with a water content of 0, and add the selected n-valeric acid into the reactor, then reduce the air pressure in the reactor to 0.05MPa, and reduce the temperature in the reactor after completing the air pressure adjustment Raise the temperature to 40°C at a uniform speed within 30 seconds, and keep it warm for 3 minutes;

[0036] S2, mix phosphorus trichloride, after completing step S1, adjust the temperature of n-valeric acid in the reactor to 48°C while keeping the pressure in the reactor constant, and then drop it into the n-valeric acid in the reactor at a constant speed within 30 minutes Add phosphorus trichloride, and when the phosphorus trichloride is added dropwise, the temperature of the n-valeric acid drops by no more than 1°C, and during the dropwise addition of the phosphorus trichloride, the mixed solut...

Embodiment 3

[0045] A method for directly producing n-valeryl chloride, comprising the following steps:

[0046] S1, mother liquor configuration, first select the n-valeric acid with a water content of 10%, and add the selected n-valeric acid into the reactor, then reduce the air pressure in the reactor to 0.03MPa, and after the air pressure adjustment is completed, the reactor The internal temperature is raised to 43°C at a constant speed within 100 seconds, and kept for 4 minutes;

[0047] S2, mix phosphorus trichloride, after completing step S1, adjust the temperature of n-valeric acid in the reactor to 46°C while keeping the pressure in the reactor constant, and then drop it into the n-valeric acid in the reactor at a constant speed within 15 minutes Add phosphorus trichloride, and when the phosphorus trichloride is added dropwise, the temperature of the n-valeric acid drops by no more than 1°C, and during the dropwise addition of the phosphorus trichloride, the mixed solution in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com