Preparation method of PDMS super-hydrophobic flexible membrane capable of being opened and closed in transparent/opaque state

A transparent state, water-flexible technology, applied in the field of preparation of super-hydrophobic flexible smart window materials, can solve the problems of reduced light scattering, decreased light transmittance, enhanced light scattering, etc., and achieves low production cost, good flexibility, and optical stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

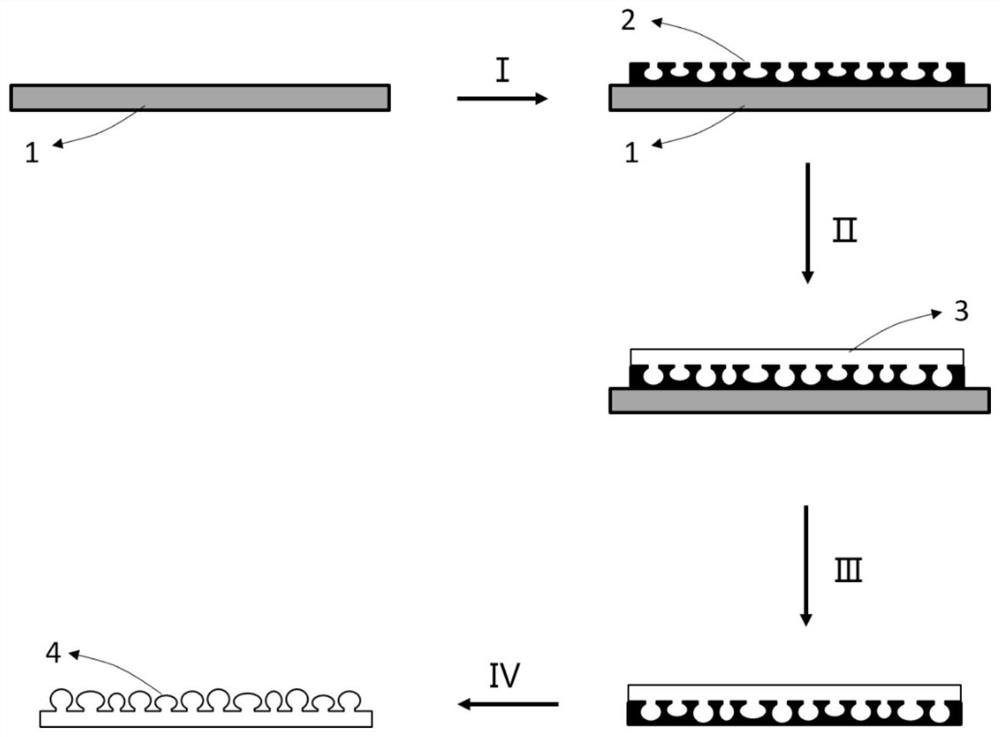

[0035] Embodiment 1: a kind of preparation method of the PDMS superhydrophobic flexible film that can switch in transparent / opaque state, specifically comprises the following steps:

[0036] 1. Prepare the solution: prepare a sodium acetate ethanol solution with a concentration of 2wt%, stir well to dissolve the sodium acetate. The PDMS precursor solution was prepared by mixing the basic components and the curing agent in a mass ratio of 10:1, stirred evenly, and left to stand for 30 minutes until all the bubbles were eliminated before use. The curing agent is commercially available PDMS supporting SYLGARD 184 curing agent.

[0037] II. Spraying: Use a spray gun to evenly spray the prepared sodium acetate ethanol solution onto the glass substrate to obtain a sodium acetate porous template; the size of the nozzle is 0.2mm, and the distance between the nozzle and the substrate is 7cm. The substrate temperature was controlled at 40°C during spraying. The thickness of the spraye...

Embodiment 2

[0043] Embodiment 2: a kind of preparation method of the PDMS superhydrophobic flexible film that transparent / opaque state can switch, specifically comprises the following steps:

[0044] 1. Prepare the solution: prepare a sodium acetate ethanol solution with a concentration of 2wt%, stir well to dissolve the sodium acetate. The PDMS precursor solution was prepared by mixing the basic components and the curing agent in a mass ratio of 10:1, stirred evenly, and left to stand for 30 minutes until all the bubbles were eliminated before use.

[0045] II. Spraying: Use a spray gun to evenly spray the prepared sodium acetate ethanol solution onto the glass substrate to obtain a sodium acetate porous template; the size of the nozzle is 0.2 mm, and the distance between the nozzle and the substrate is 7 cm. The substrate temperature was controlled at 70°C during spraying. The thickness of the sprayed layer is controlled at 30-50 microns.

[0046] Ⅲ. Curing: Pour the prepared PDMS pre...

Embodiment 3

[0048] Embodiment 3: a kind of preparation method of the PDMS superhydrophobic flexible film that can switch in transparent / opaque state, specifically comprises the following steps:

[0049] 1. Prepare the solution: prepare a sodium acetate ethanol solution with a concentration of 5wt%, stir well to dissolve the sodium acetate. The PDMS precursor solution was prepared by mixing the basic components and the curing agent in a mass ratio of 10:1, stirred evenly, and left to stand for 30 minutes until all the bubbles were eliminated before use.

[0050] II. Spraying: Use a spray gun to evenly spray the prepared sodium acetate ethanol solution onto the glass substrate to obtain a sodium acetate porous template; the size of the nozzle is 0.2 mm, and the distance between the nozzle and the substrate is 7 cm. The substrate temperature was controlled at 70°C during spraying. The thickness of the sprayed layer is controlled at 30-50 microns.

[0051] Ⅲ. Curing: Pour the prepared PDMS ...

PUM

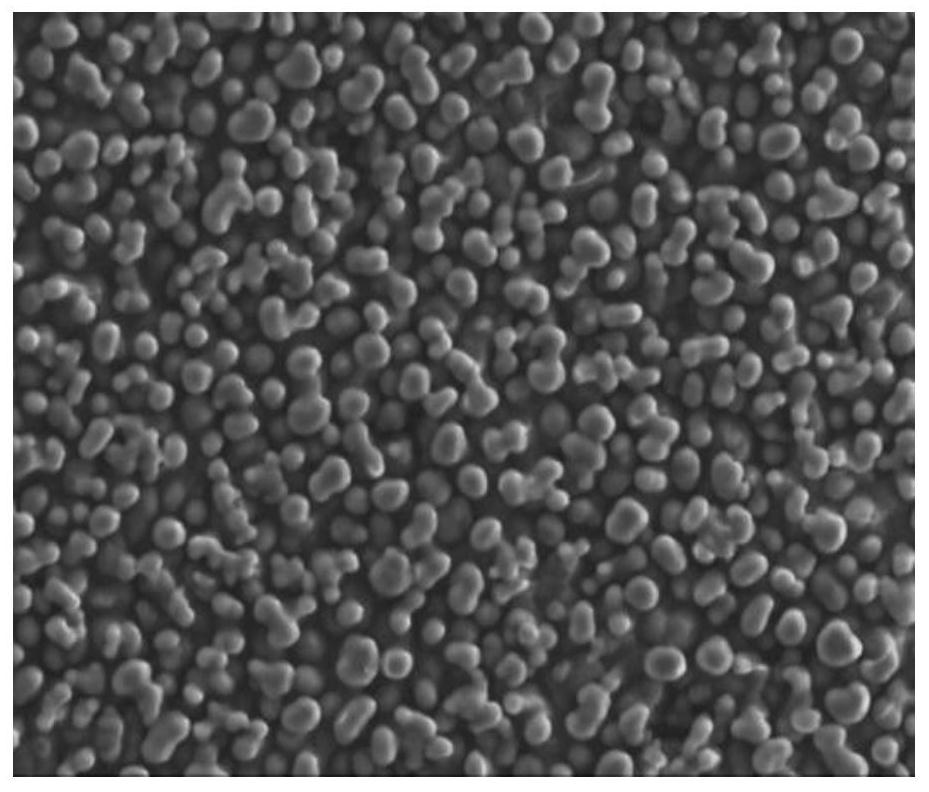

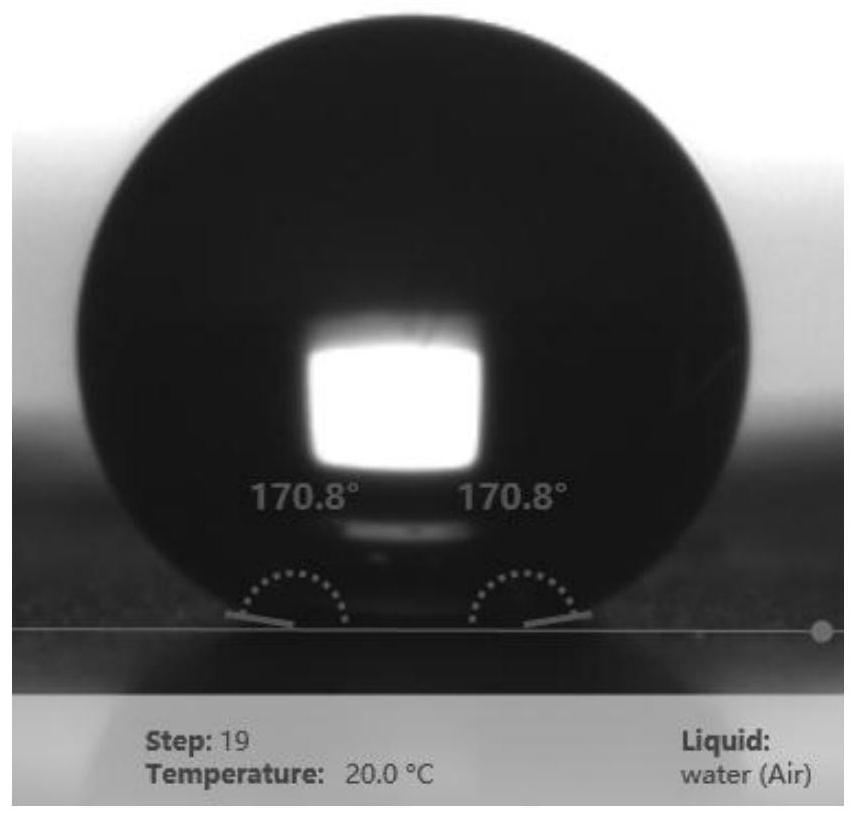

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com