Garbage cracking gasification device

A technology for pyrolysis gasification and garbage, which is applied in gasification process, fixed bed gasification, production of combustible gas, etc. It can solve the problems of low pyrolysis gasification efficiency, difficult to control reaction state, limited amount of combustible gas, etc., and achieve stable output. , high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

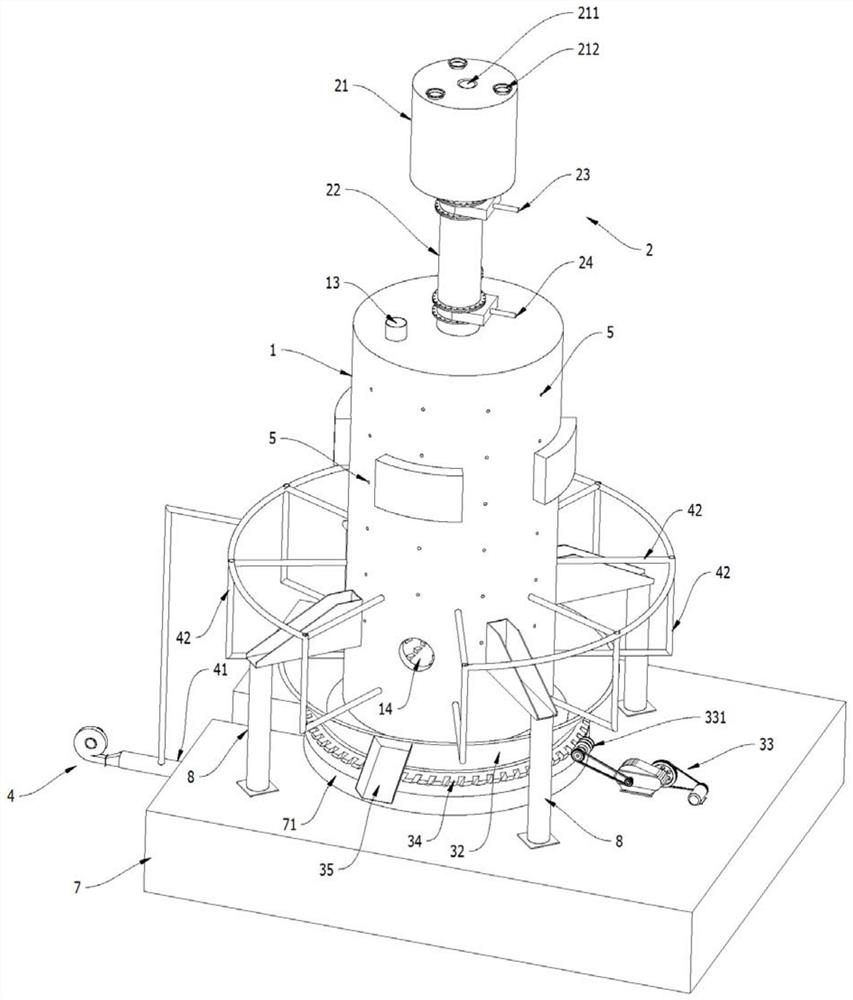

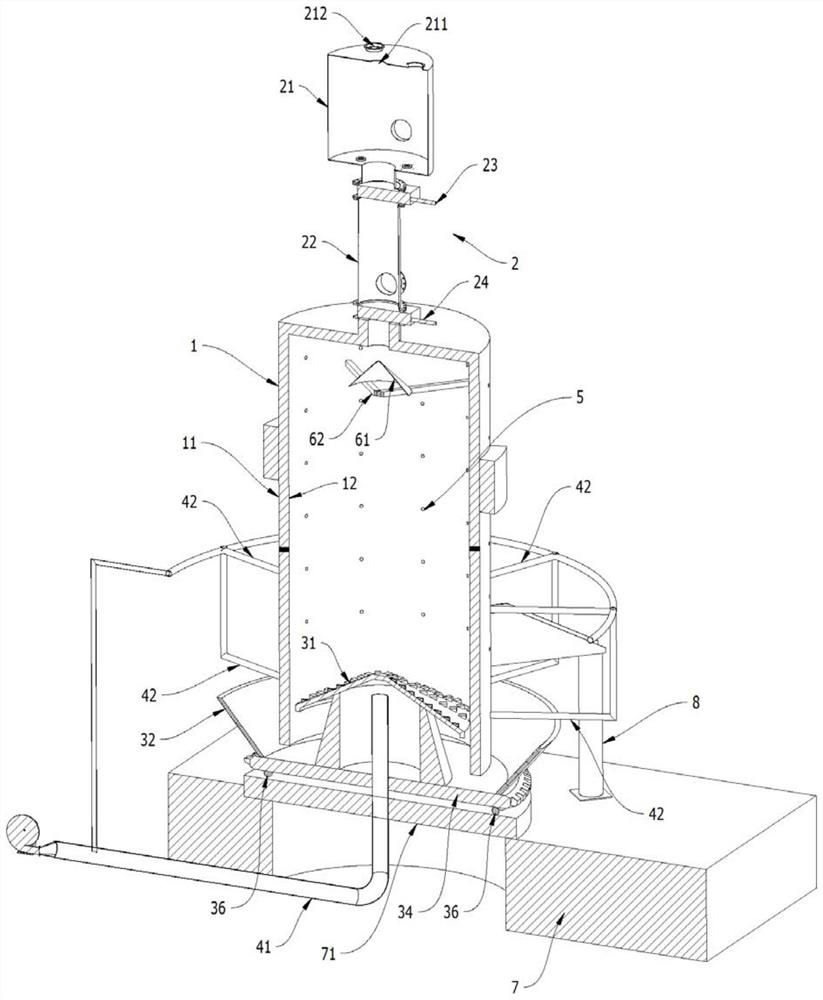

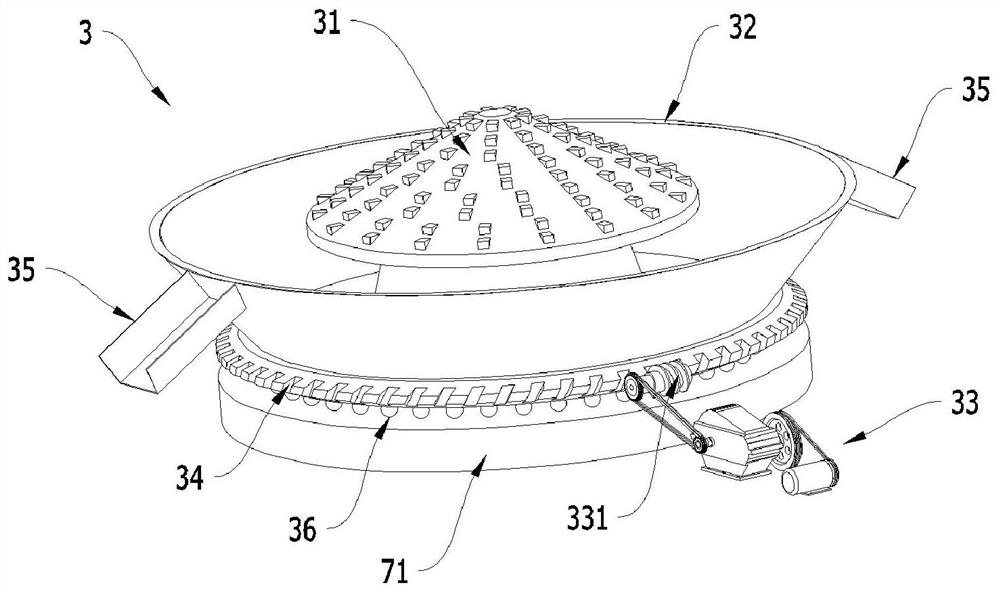

[0046] refer to figure 1 As shown, this embodiment provides a garbage cracking gasification device, including: a furnace body 1, a feeding device 2, a slag removal device 3, a wind pressure system 4, a temperature sensor 5, a material distribution mechanism 6, a base 7 and a column 8 .

[0047] Furnace body 1 ; the furnace wall of the furnace body 1 includes an outer cylinder 11 and an inner cylinder 12 . Both the outer cylinder 11 and the inner cylinder 12 are welded with steel plates, and the inside is smooth. A transverse partition is also provided between the outer cylinder 11 and the inner cylinder 12 to divide the space between the outer cylinder 11 and the inner cylinder 12 into upper and lower water jackets. Both the upper and lower water jackets are filled with cooling water, and water inlet pipes and water outlet pipes (not shown in the figure) are provided in the upper and lower water jackets. The inner wall of the conventional garbage cracking gasifier is cut wi...

Embodiment 2

[0060] This embodiment provides a control method for a control system of a garbage cracking and gasification device. The control system of the garbage cracking and gasification device includes: a feeding control unit, a furnace temperature control unit, a wind pressure control unit, and a slag removal control unit; The method includes the following steps:

[0061] S1, obtain the garbage block to be fed, and put it into the feeding device 2;

[0062] Specifically, the garbage block in step S1 is a compressed block after dehydration, and the length of the garbage block is 4-6 cm, preferably 5 cm; the width is 3-5 cm, preferably 4 cm; the height is 3-6 cm. 5cm, preferably 4cm. After the pre-treatment, the garbage block has been dehydrated and compressed into a block, which is beneficial to the controllability of the feeding of the garbage and the uniformity of the burning, cracking and gasification of the garbage.

[0063] S2, start the feeding control unit, put the garbage blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com