Preparation method of spectrum blue shift noctilucent fiber

A luminous fiber and blue-shifting technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, and single-component polyester rayon, can solve problems such as monotonous luminous color, achieve good washing resistance, and expand the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

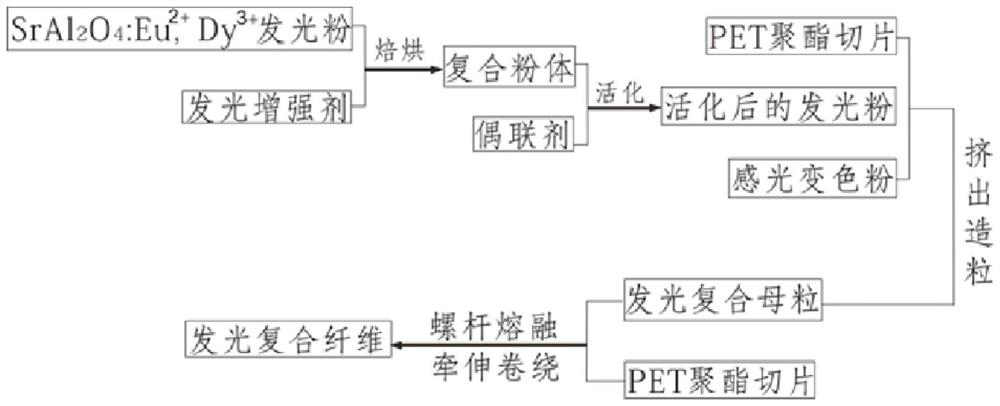

[0021] This embodiment discloses a preparation method of a luminous fiber with a blue-shifted spectrum, comprising the following steps:

[0022] (1) Activation treatment: SrAl 2 o 4 : Eu 2+ , Dy 3+ The luminescent powder and the luminescence enhancer are mixed according to the weight ratio of 0.5:1, and the composite powder is obtained after baking in a microwave calciner, and then the relative SrAl 2 o 4 : Eu 2+ , Dy 3+ 5% of the coupling agent by weight of the luminescent powder is used to activate the composite powder to obtain activated SrAl 2 o 4 : Eu 2+ , Dy 3+ glow powder.

[0023] Specifically, the baking temperature in the microwave calciner is 300° C., and the baking time is 1 h. The luminescence enhancer is rice husk carbon powder, and the particle size of the luminescence enhancer is 50nm. The coupling agent is silane coupling agent KH550.

[0024] (2) Preparation of luminescent composite masterbatch: 10 parts by weight of PET polyester chips, 1 part b...

Embodiment 2

[0029] This embodiment discloses a preparation method of a luminous fiber with a blue-shifted spectrum, comprising the following steps:

[0030] (1) Activation treatment: SrAl 2 o 4 : Eu 2+ , Dy 3+ The luminescent powder and the luminescence enhancer are mixed according to the weight ratio of 3:1, and the composite powder is obtained after baking in a microwave calciner, and then the relative SrAl 2 o 4 : Eu 2+ , Dy 3+ 10% of the coupling agent by weight of the luminescent powder is used to activate the composite powder to obtain activated SrAl 2 o 4 : Eu 2+ , Dy 3+ glow powder.

[0031] Specifically, the baking temperature in the microwave calciner is 400° C., and the baking time is 2 hours. The luminescence enhancer is volcanic powder, and the particle size of the luminescence enhancer is 500nm. The coupling agent is silane coupling agent KH560.

[0032] (2) Preparation of luminescent composite masterbatch: 50 parts by weight of PET polyester chips, 10 parts by ...

Embodiment 3

[0037] This embodiment discloses a preparation method of a luminous fiber with a blue-shifted spectrum, comprising the following steps:

[0038] (1) Activation treatment: SrAl 2 o 4 : Eu 2+ , Dy 3+ The luminescent powder and the luminescent enhancer are mixed according to the weight ratio of 5:1, and the composite powder is obtained after baking in a microwave calciner, and then the relative SrAl 2 o 4 : Eu 2+ , Dy 3+ 20% of the coupling agent by weight of the luminescent powder is used to activate the composite powder to obtain activated SrAl 2 o 4 : Eu 2+ , Dy 3+ glow powder.

[0039]Specifically, the baking temperature in the microwave calciner is 500° C., and the baking time is 3 hours. The luminescence enhancer is coconut shell carbon powder, and the particle size of the luminescence enhancer is 1000nm. The coupling agent is silane coupling agent KH570.

[0040] (2) Preparation of luminescent composite masterbatch: 90 parts by weight of PET polyester chips, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com