Construction technology of equal-thickness cement-soil stirring continuous wall

A technology of cement-soil mixing and construction technology, which is applied in sheet pile wall, foundation structure engineering, earth mover/shovel and other directions to achieve the effects of good construction quality, reduced cutting construction difficulty, and low wall fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

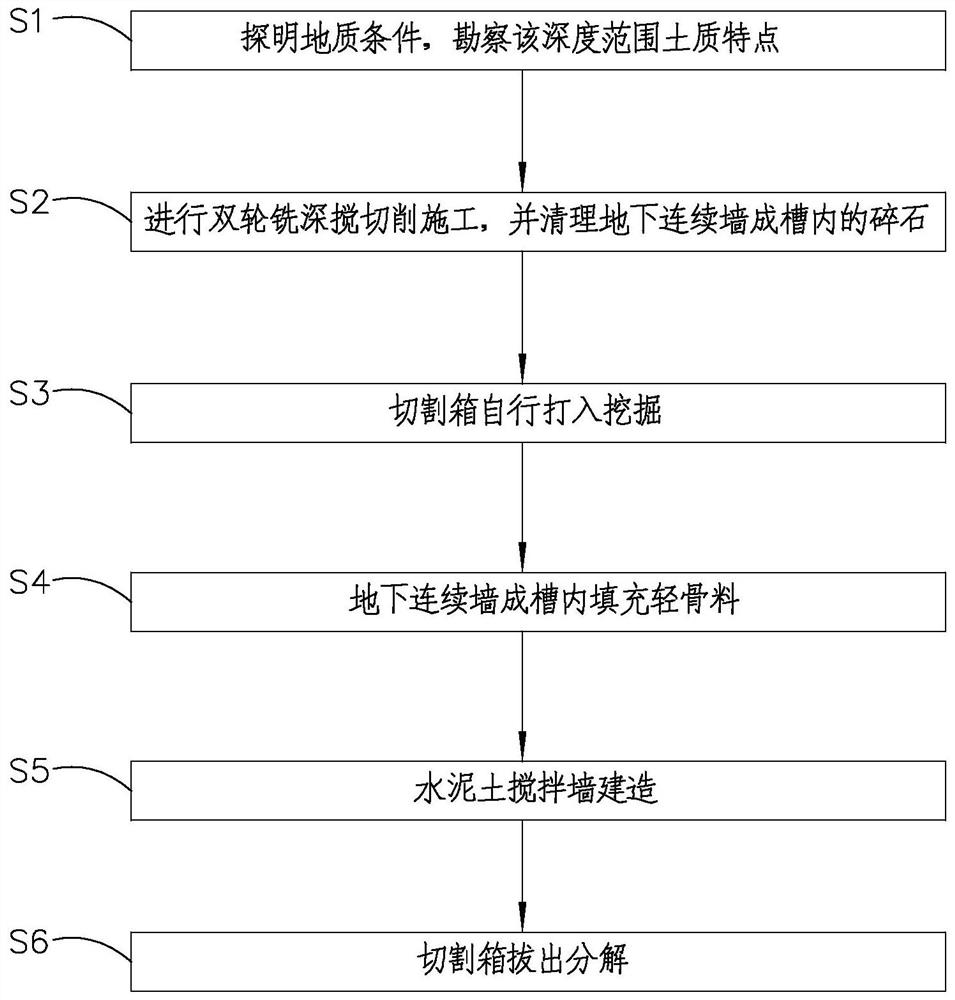

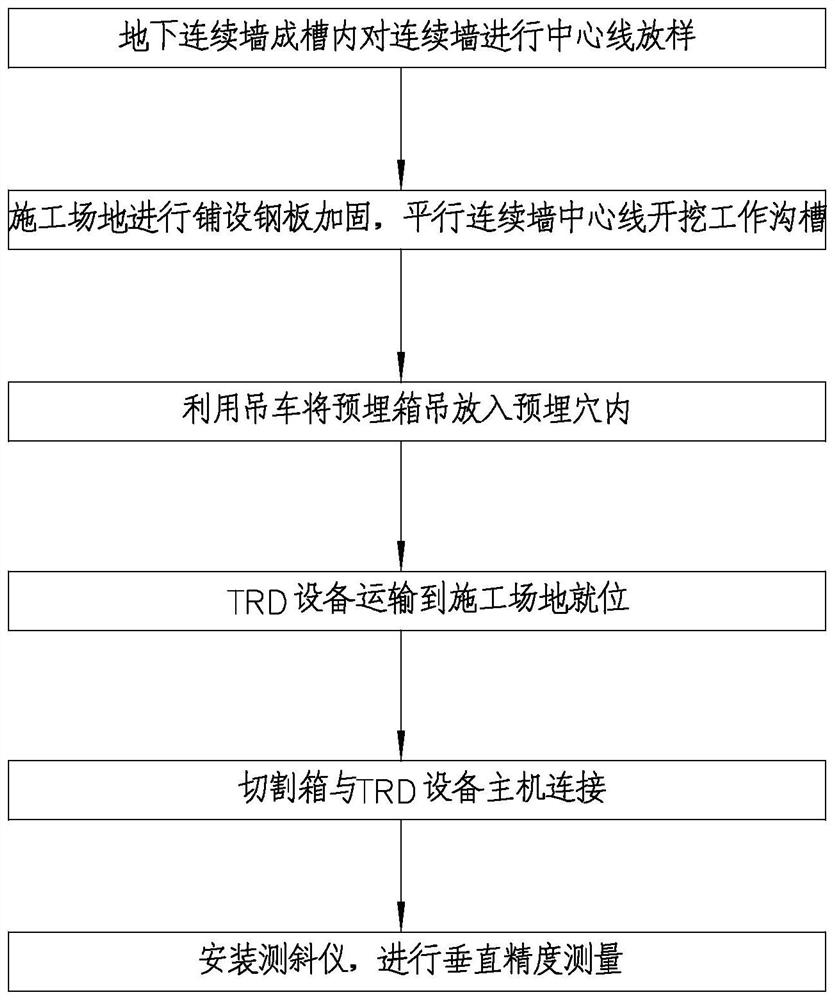

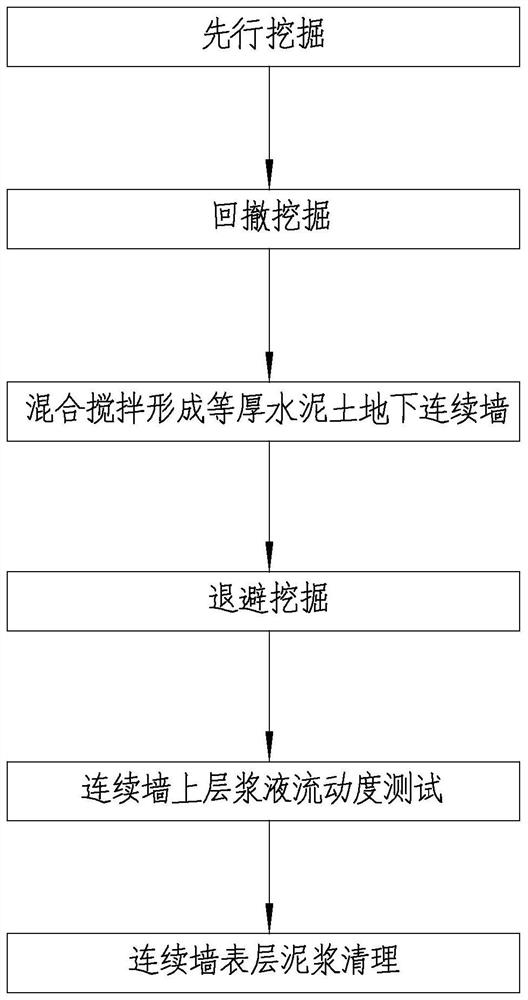

[0047] The following is attached Figure 1-3 The application is described in further detail.

[0048] The embodiment of the present application discloses a construction process of a constant-thickness cement-soil mixing continuous wall. refer to figure 1 , the construction process includes the following steps;

[0049]S1. Ascertain the geological conditions and survey the soil characteristics in the depth range;

[0050] When the geological conditions are verified, the depth of the rock layer is verified, the construction plan is designed according to the verified results, and the excavation plan is determined according to the characteristics of the soil.

[0051] S2. Carry out double-wheel milling and deep stirring cutting construction, and clean up the gravel in the groove of the underground diaphragm wall;

[0052] Choose the double-wheel milling and deep stirring equipment with strong cutting performance for cutting. Before cutting, dig out the soil layer and place it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com