Environment-friendly plastic floor

A kind of plastic floor, environment-friendly technology, applied in the field of plastic floor, can solve the problems of affecting the flatness of the floor, damaging electronic components, wasting time, etc., to achieve the effect of enhancing structural strength, improving flame retardancy, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

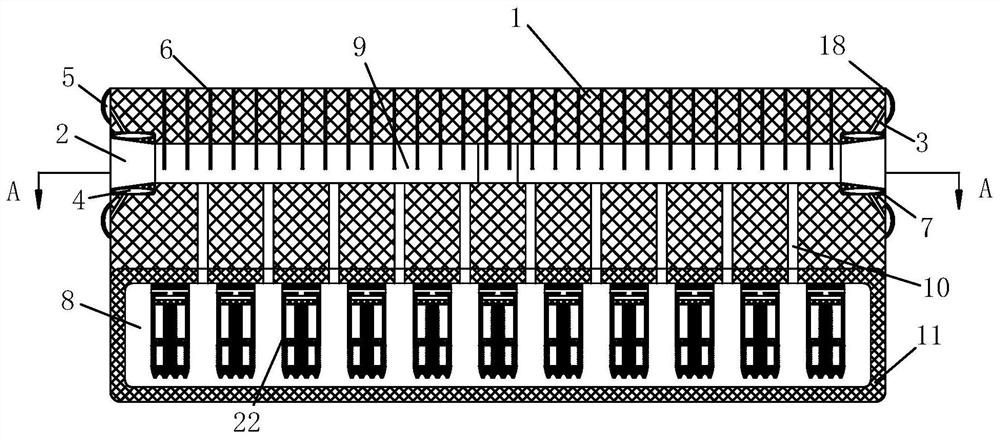

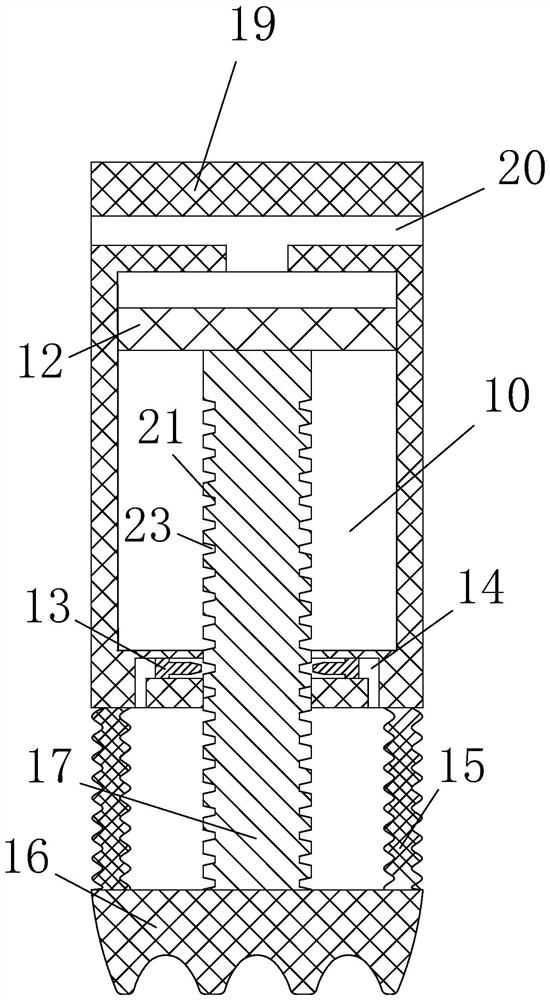

[0023] As an embodiment of the present invention, the support unit 19 includes a fixed rod 22, a support rod 17, a support pad 16 and an elastic film 15; the upper end of the fixed rod 22 is fixedly connected to the top inner wall of the rubber layer 11, and the fixed rod 22 A water pressure chamber is opened inside; a blocking plate 12 is sealed and slidably connected in the water pressure chamber; the upper end of the support rod 17 is fixedly connected to the lower surface of the blocking plate 12, and the lower end of the support rod 17 passes through the fixing rod 22 through a perforation and is placed on the The lower side of the fixed rod 22 is fixedly connected to the upper surface of the support pad 16, and the support rod 17 is slidably connected to the fixed rod 22; the lower surface of the fixed rod 22 is fixedly connected to the upper surface of the support pad 16 with an elastic film 15; the elastic film 15 has a ring design , and the elastic membrane 15 wraps th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com