Flexible connecting device for IV-type tube bundle bottle and container frame

A flexible connection and container technology, applied in the installation device of the container structure, the geometry/arrangement/size of the container structure, packaging, etc., can solve the problems that have not been considered, achieve a large amount of thermal deformation, and improve the overall stress and deformation status , Improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

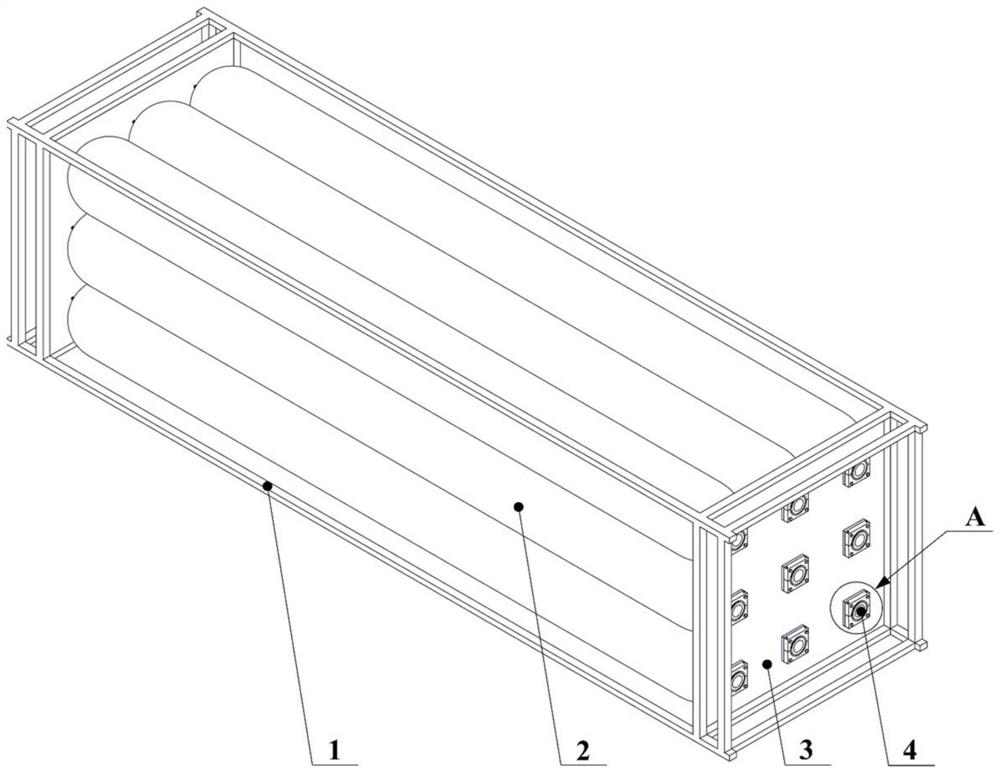

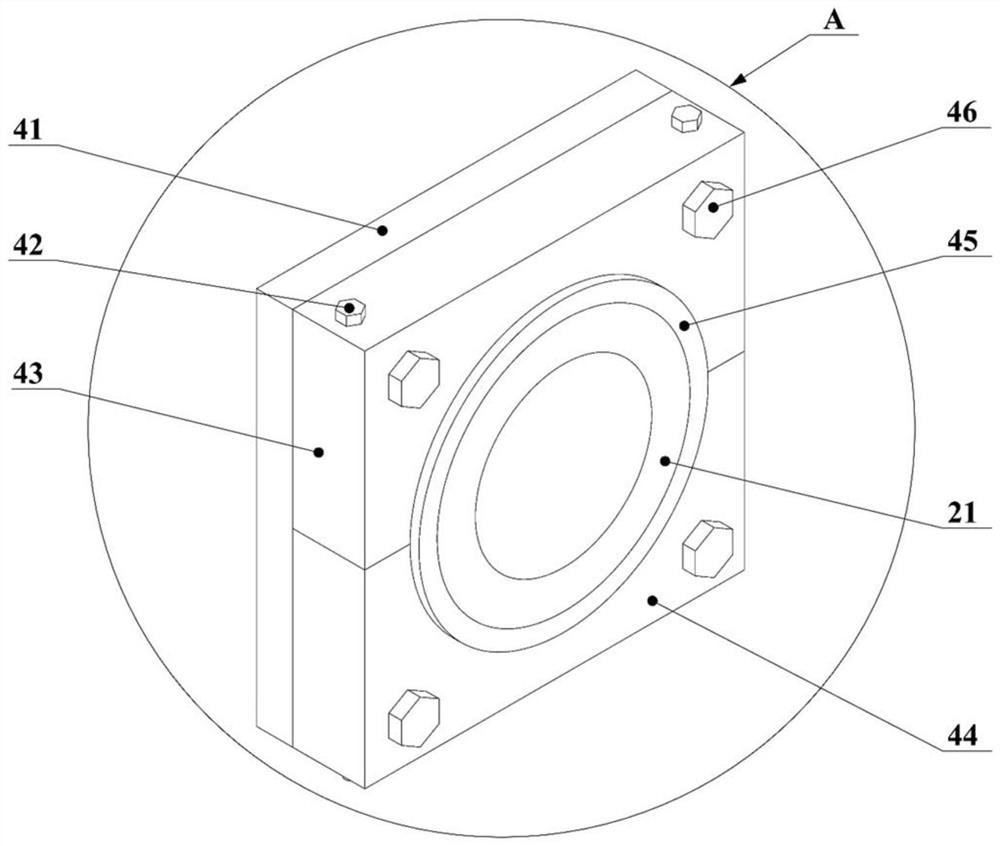

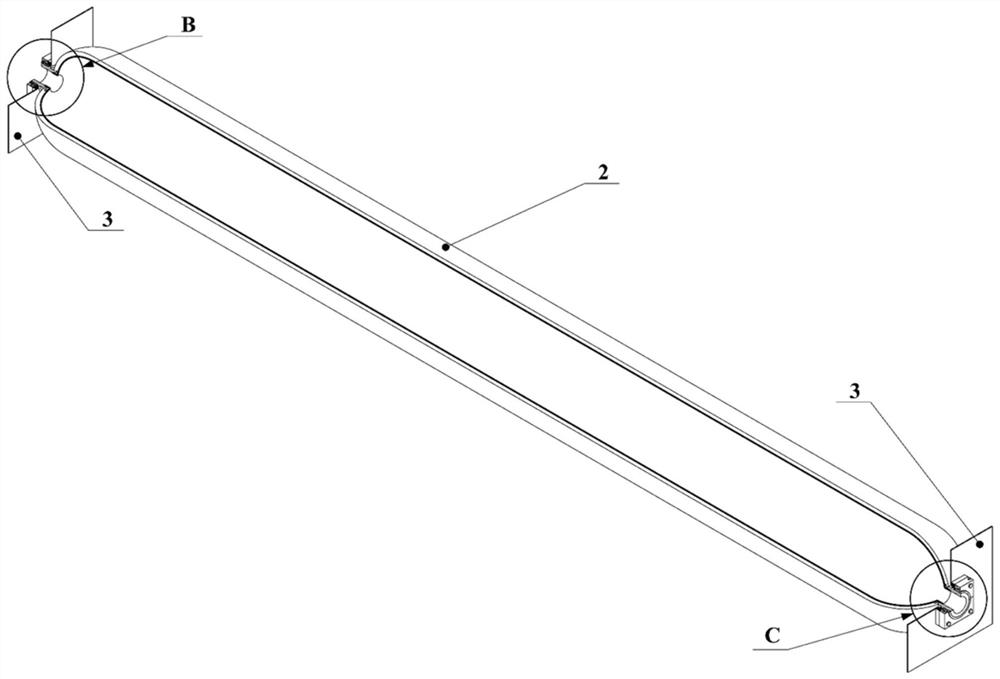

[0041] figure 1 The shown embodiment 1 is a container composed of nine large-capacity IV-type tube bundle bottles 2 placed horizontally, and a 3×3 tube bundle bottle arrangement is adopted. Wherein, the support plate 3 is fixedly connected with the container frame 1 by welding. On the basis of not changing the container frame structure and tube bundle arrangement, the present invention provides a flexible connection device for type IV tube bundle bottle and container frame, such as Figure 2-Figure 17 As shown, it is arranged between the bottle mouth of the tube bundle boss structure 21 and the support plate 3, including a damping block 41, an anti-rotation block 47, a bushing 45, an upper clamping block 43, a lower clamping block 44, and an adjusting gasket 48 , hoop long bolt 421 and nut 422 and fastening bolt 461 and nut 462 etc.

[0042] Such as image 3 As shown, in this embodiment, the flexible connection device at the left end of the IV-type tube bundle bottle 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com