Slewing bearing fault diagnosis method and device and storage medium

A technology of fault diagnosis device and slewing bearing, which is applied in the direction of measuring device, complex mathematical operation, instrument, etc., to achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The invention is further described in detail below with reference to the accompanying drawings and examples. It is particularly pointed out that the following examples are intended to illustrate the invention, but are not limited thereto. Similarly, the following examples are only the various embodiments of the invention, and all other embodiments obtained by those of ordinary skill in the art without all other embodiments obtained without creative labor premise.

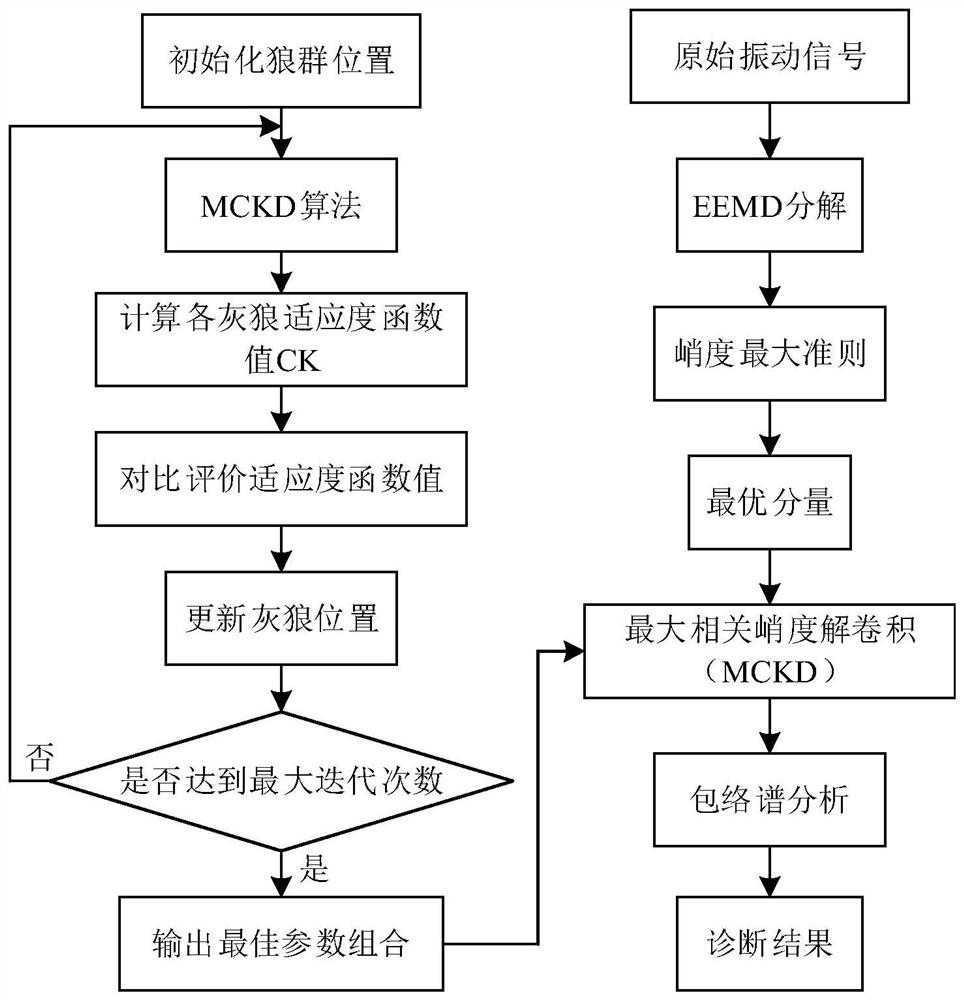

[0054] reference figure 1 As shown, the rotary support fault diagnosis method of the present embodiment employs the EEMD and GWO-MCKD binding method for low speed heavy-load door crane rotation support fault feature extraction, the specific steps are as follows:

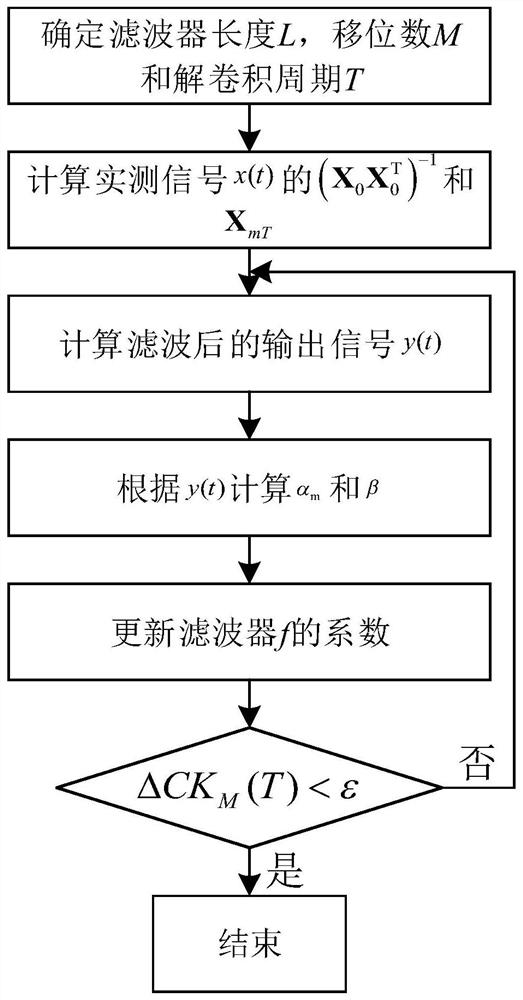

[0055] (1) Determine the parameters of the EEMD algorithm. There are two parameters that require human settings in EEMD: the standard deviation of Gaussia white noise and the number of additional noise. The standard difference is determined according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com