Large-angle liquid crystal optical phased array scanning assembly

A liquid crystal optics and phased array technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of narrow beam scanning range, high cost, large beam insertion loss, etc., and achieve the effect of solving the narrow field of view.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

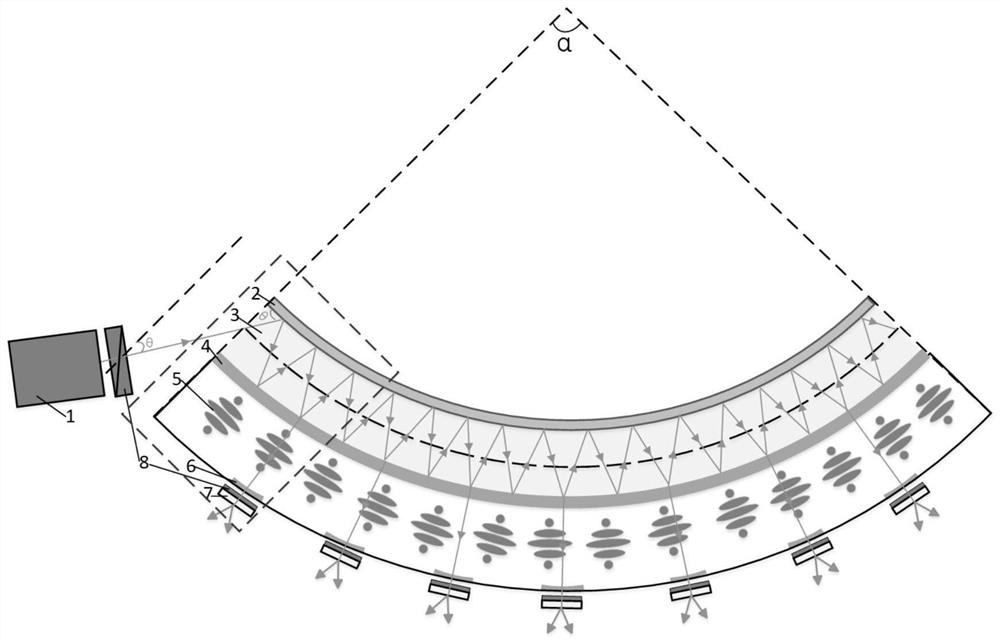

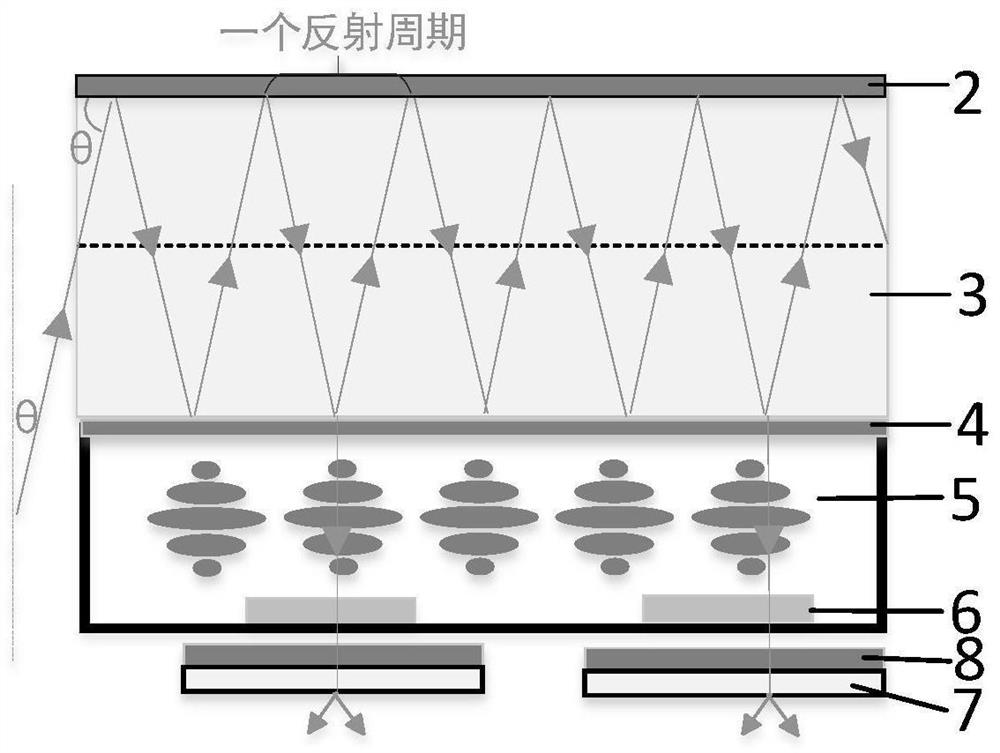

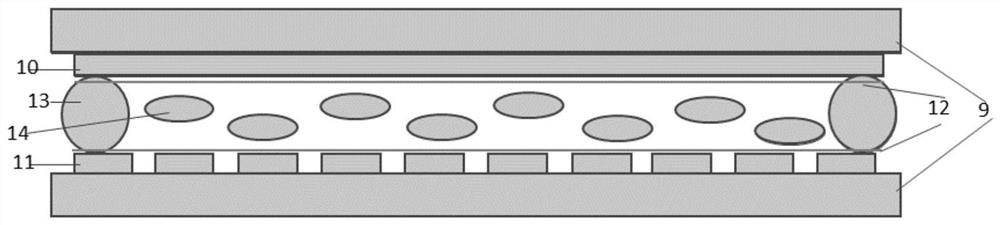

[0020] Such as figure 1 As shown, a large-angle liquid crystal optical phased array scanning assembly of the present invention includes a laser 1, a quarter wave plate, an optical waveguide 3, a cholesteric liquid crystal device 5 and a liquid crystal optical phased array 7; the laser 1 emits The laser is coupled into the optical waveguide 3 after passing through a quarter wave plate, and propagates along the optical waveguide; the optical waveguide 3 is in an arc-shaped structure, and the inner side of the optical waveguide 3 is provided with a metal reflective layer 2, and the outer side is provided with an ITO film layer 4 The outside of the ITO film layer 4 is provided with a plurality of cholesteric liquid crystal devices 5, and the outside of the cholesteric liquid crystal device 5 is successively provided with an ITO electrode 6, a quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com