Intelligent factory industrial internet system architecture

A technology of industrial Internet and architecture, applied in the field of industrial Internet system architecture of smart factories, can solve the problems of untimely response of sensor data, achieve the effect of reducing the transmission of repeated data, increasing the speed of data reading and writing, and avoiding delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

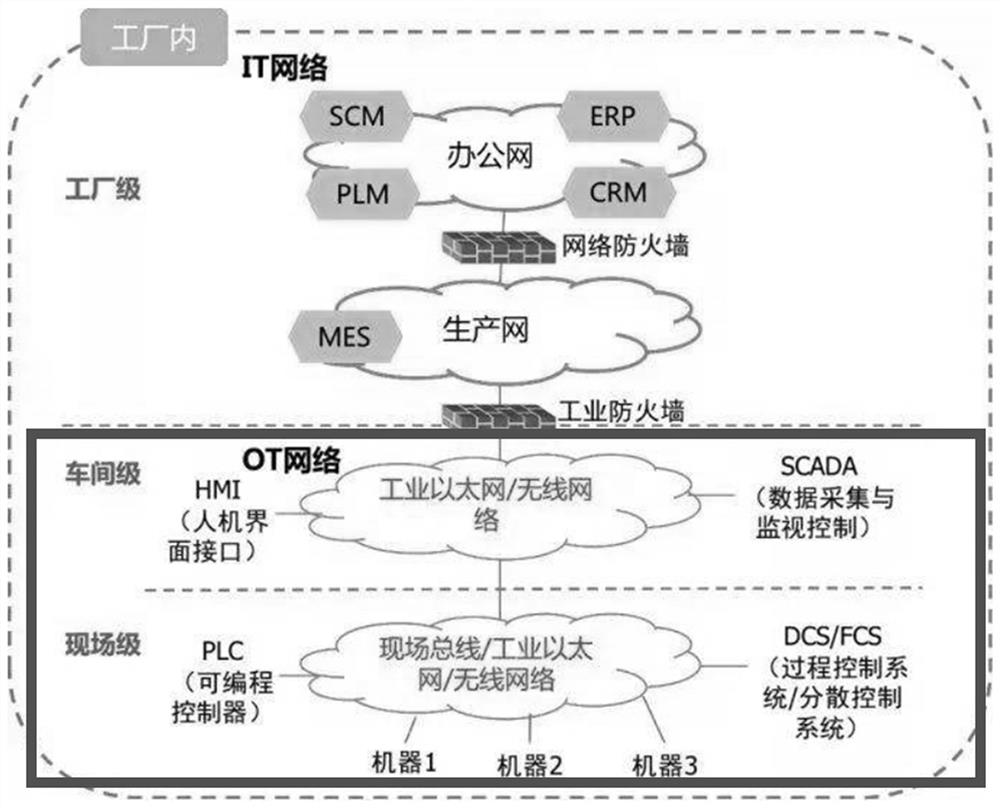

[0017] Such as figure 1 As shown, a schematic diagram of a traditional three-level industrial network is given, which consists of a factory-level network, a workshop-level network, and a field-level network. The factory-level network includes an office network and a production network. The workshop-level network consists of industrial Ethernet and / or wireless Network composition, with human-machine interface interface, to realize data acquisition and monitoring control; field-level network is composed of field bus, industrial Ethernet and / or wireless network, which can be used in process controllable system (DCS) and distributed control system (FCS) Under the control of the programming controller PLC, the on-site machines and other equipment are controlled. Among them, the first-level network (factory-level network) and the second-level network (works...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com