New energy automobile battery heat dissipation mechanism

A technology of new energy vehicles and heat dissipation mechanism, which is applied in the direction of secondary battery, battery cover/end cover, battery pack parts, etc. Impact ability, unable to improve the cooling effect of the heat dissipation mechanism on the battery pack, etc., to achieve the effect of improving the cooling effect, improving the use effect, and ensuring normal heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

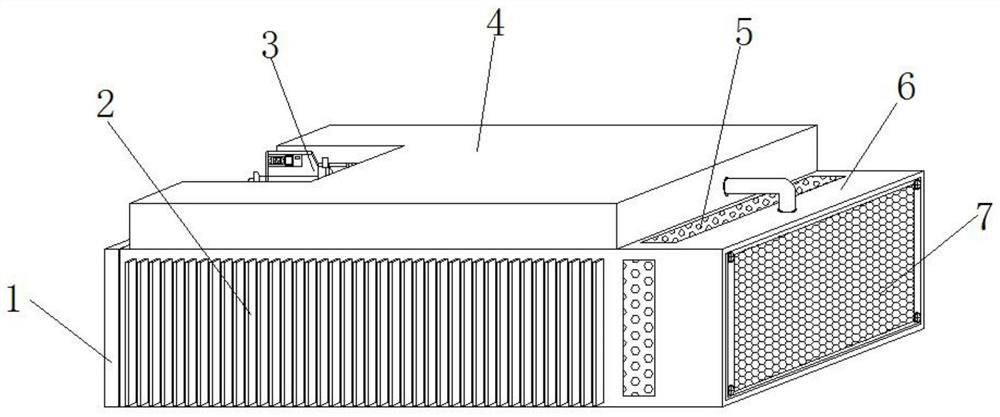

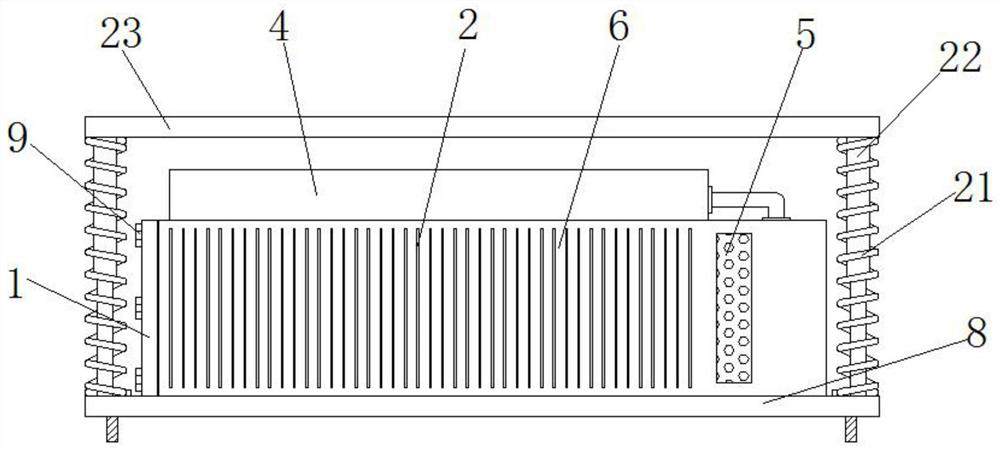

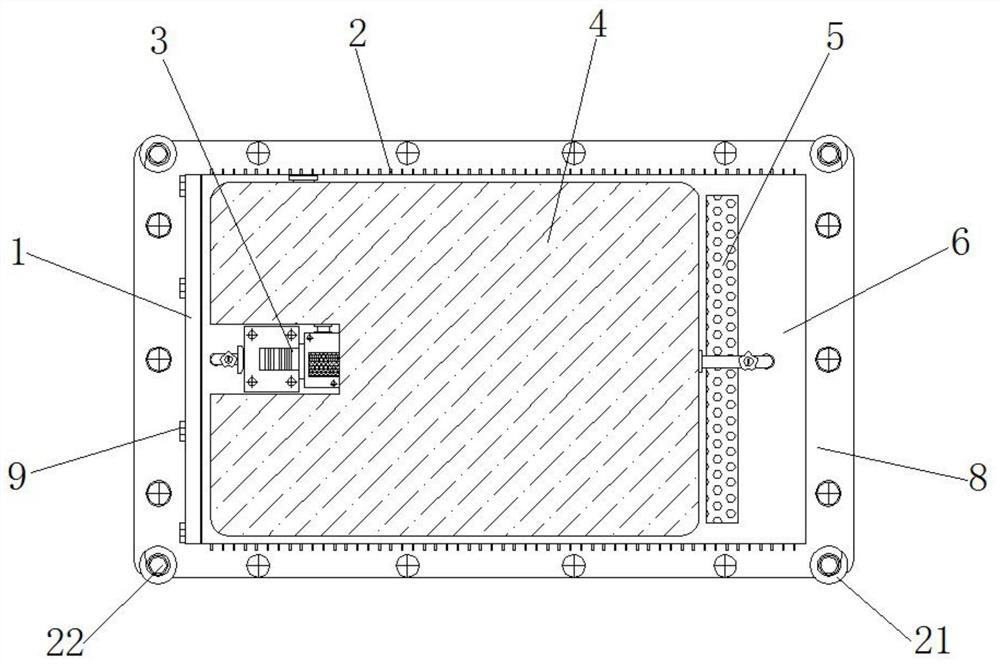

[0039] Example 1, such as Figure 1-5 As shown, when the top of the heat dissipation mechanism is hit, the telescopic rod 22 is shortened, the buffer spring 21 is shortened by force and stores elastic potential energy, and the impact force at the top of the heat dissipation mechanism is buffered. If the bottom of the top plate 23 continues to descend and squeeze to The coolant tank 4, the coolant tank 4 can be used as the second step of buffer protection, and finally the car battery pack 10 can be finally protected through the main body compartment 6, so that when the top of the vehicle is hit, the use of three sets of protective structures can greatly improve the performance of the main body. The safety of the car battery pack 10 inside the compartment 6.

Embodiment 2

[0040] Example 2, such as Figure 1-7 As shown, when the automobile battery pack 10 generates heat during operation, the water pump 3 is controlled by an external control panel to transport the coolant inside the coolant tank 4 to the inside of the heat exchange tube 12, and the coolant passes through the heat exchange tube 12 to enter the cooling In the process inside the tube 14, since the heat exchange tube 12 surrounds the car battery pack 10, the coolant can fully absorb the heat generated by the car battery pack 10, and the heat generated at the end of the car battery pack 10 away from the mounting cover 1 passes through the heat conducting plate 18 is passed to the heat dissipation rod 16, and then two groups of fans 15 are controlled to blow the outside air into the cavity between the filter screen 7 and the partition 17. The group of cooling rods 16 is blown to cool down, and the air with heat is discharged to the external environment through the exhaust hole 5 outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com