Resistance reduction device based on negative pressure type sliding plasma discharge

A plasma and drag reduction device technology, applied in the direction of plasma, electrical components, etc., can solve the problems of single induced jet direction, small discharge area, low induction speed, etc., and achieve good adaptability, increase kinetic energy, and increase instantaneous electromotive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

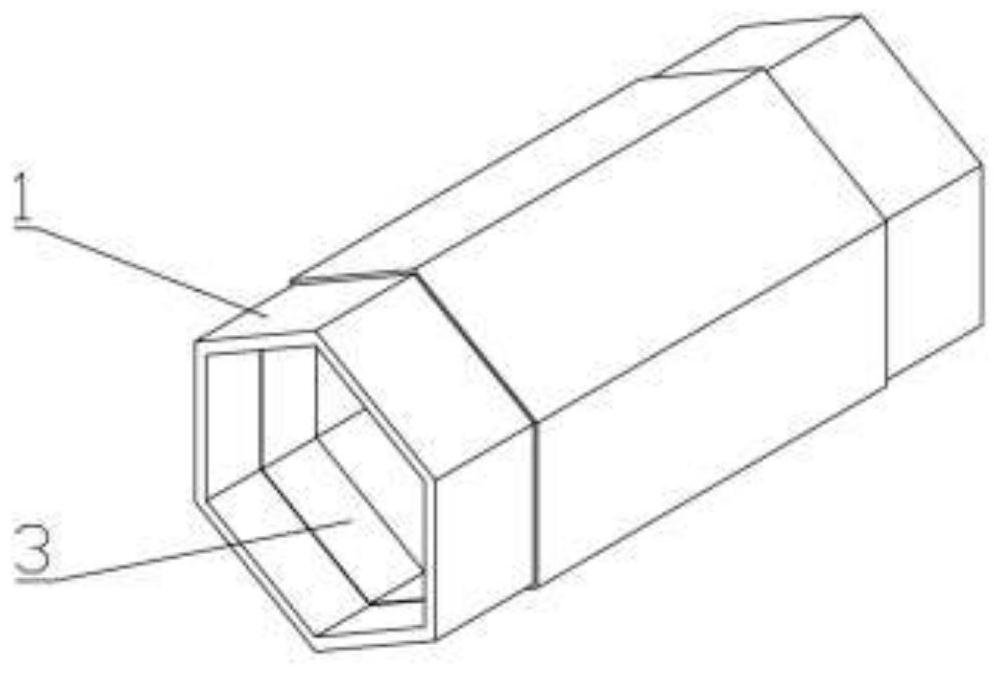

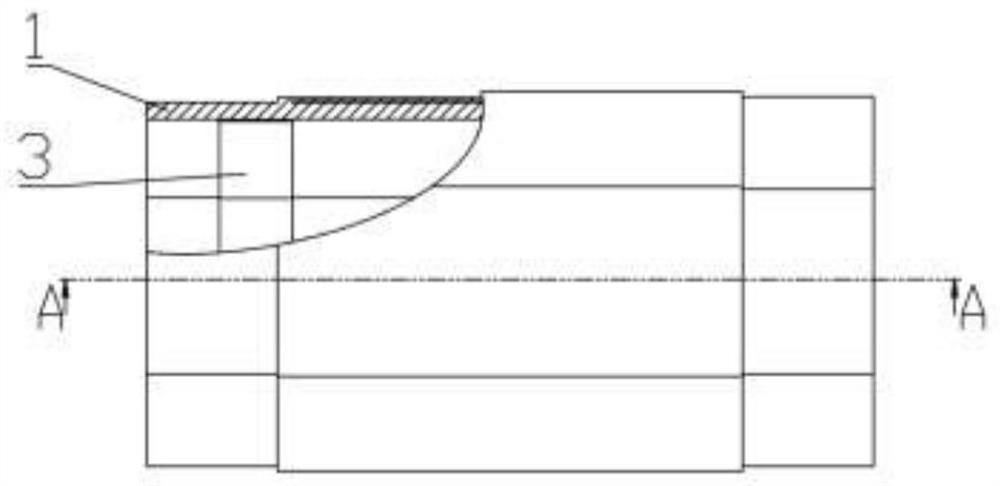

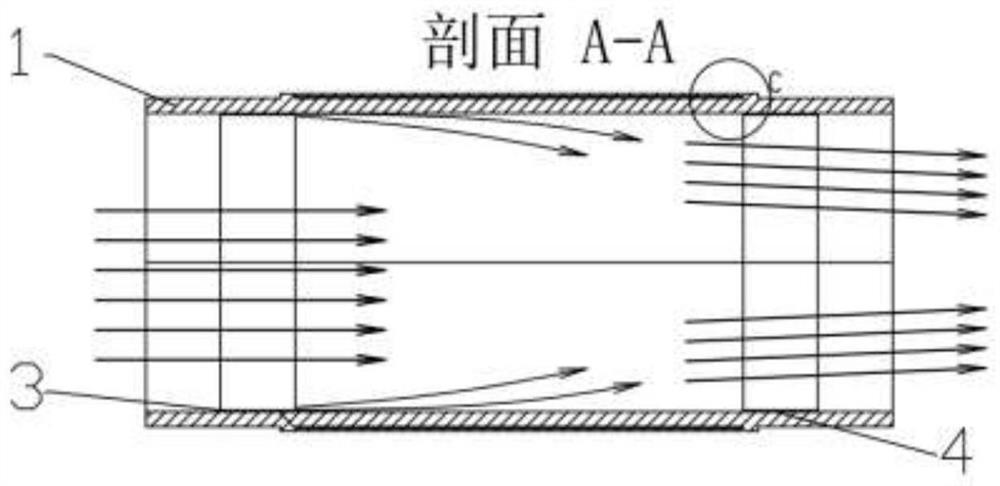

[0029] The present invention is a drag reducing device based on negative pressure sliding plasma discharge, such as Figure 1-7 As shown, it includes a mounting plate 5, and several plasma discharge units arranged in an array without gaps are installed on the mounting plate 5. When in use, the plasma discharge units are arranged perpendicular to the surface of the plate; the plasma discharge unit includes positive six The ribbed tubular dielectric layer 1 is provided with an AC electrode 3 and a pulsed DC electrode 4 along the inner wall surface of the regular hexagonal tubular dielectric layer 1, and a buried electrode is embedded in the regular hexagonal tubular dielectric layer 1 corresponding to the AC electrode 3 and the pulsed DC electrode 4. 2. The buried electrode 2, the AC electrode 3 and the pulsed DC electrode 4 are all regular hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com