Glass fiber reinforced concrete and preparation method thereof

A technology for reinforcing concrete and glass fiber, applied in the field of building materials, can solve problems such as cracking, and achieve the effects of improving crack resistance and impermeability, increasing stiffness, and enhancing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A kind of preparation method of above-mentioned glass fiber reinforced concrete, comprises the following steps:

[0060] mixing the cement, quartz sand, silane-based water repellent and acryl ether copolymer, and then adding the alkali-resistant glass fiber chopped strands to prepare cement mortar;

[0061] After pouring a part of the cement mortar, place the three-dimensional fabric, apply prestress to the three-dimensional fabric, and then continue pouring the remaining part of the cement mortar for curing.

[0062] Prestressing is applied to the three-dimensional fabric, and the pre-tensioning process is used to pre-stretch the three-dimensional fabric so that the fibers are stressed and compressed before being loaded, which can delay the development of cracks, increase the stiffness of the component, and improve the The utilization efficiency of materials facilitates the follow-up to better play the role of high-performance fabrics, improves the crack resistance and...

Embodiment 1

[0078] This embodiment provides a glass fiber reinforced concrete and a preparation method thereof, the steps are as follows:

[0079] 1) Take the following raw materials in parts by weight:

[0080]

[0081] 2) Preparation of glass fiber reinforced concrete

[0082] After installing the bottom film, get a template with length*width*height of 1200mm*1200mm*10mm, and apply the release agent.

[0083] mixing the cement, quartz sand, silane-based water-repellent and acryl ether copolymer, and then adding the alkali-resistant glass fiber chopped strands to prepare cement mortar.

[0084] In the formwork, a part of the above-mentioned cement mortar was poured to a height of 3 mm, and vibrated with a micro vibrator.

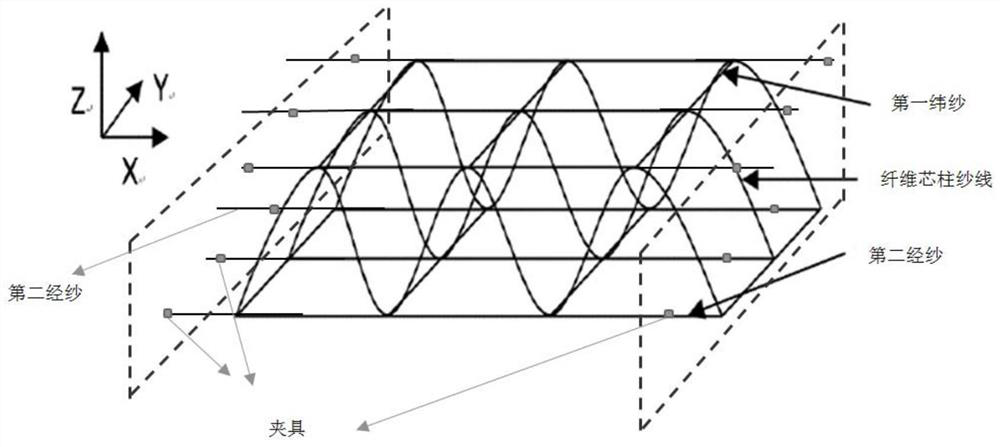

[0085] Place the 3D fabric provided by Changzhou Bolong 3D Composite Material Co., Ltd., such as figure 1 As shown, the first warp yarn of the first fabric layer of the three-dimensional fabric and the second warp yarn of the second fabric layer are respectively ...

Embodiment 2

[0089] This embodiment provides a glass fiber reinforced concrete and a preparation method thereof, which are basically the same as in Embodiment 1, the main difference being that the method of applying prestress is different, and the steps are as follows:

[0090] 1) Take the following raw materials in parts by weight:

[0091]

[0092] 2) Preparation of glass fiber reinforced concrete

[0093] After installing the bottom film, get a template with length*width*height of 1200mm*1200mm*10mm, and apply the release agent.

[0094] mixing the cement, quartz sand, silane-based water-repellent and acryl ether copolymer, and then adding the alkali-resistant glass fiber chopped strands to prepare cement mortar.

[0095] In the template, first pour a part of the above cement mortar to a height of 3mm, and vibrate with a micro vibrator.

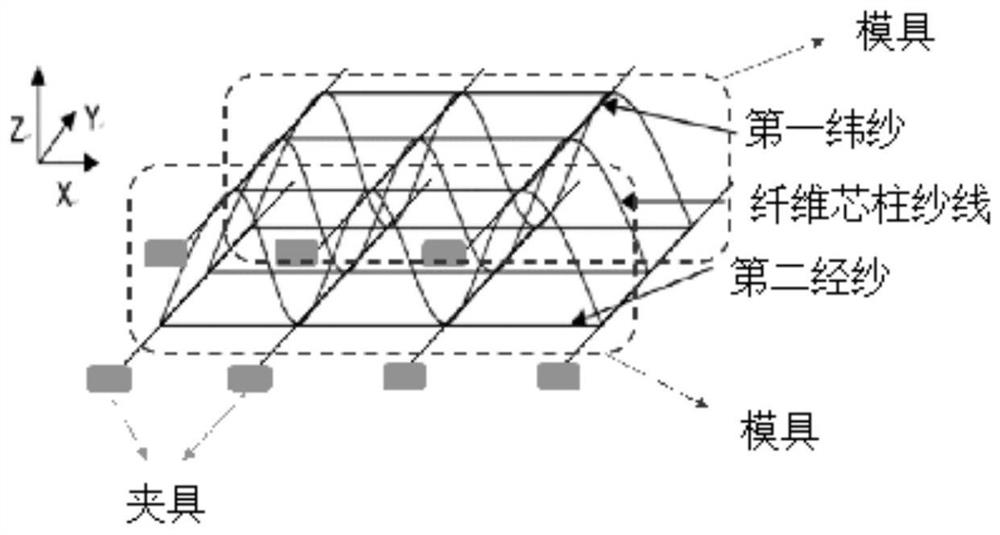

[0096] Place the 3D fabric provided by Changzhou Bolong 3D Composite Material Co., Ltd., such as figure 2 As shown, the first weft yarn of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com