A method for preparing polyurethane foam that can settle rapidly in water

A polyurethane foam and fast technology, which is applied in the field of polymer material preparation, can solve the problems of high cost and tediousness, and achieve the effects of good rebound, good physical strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

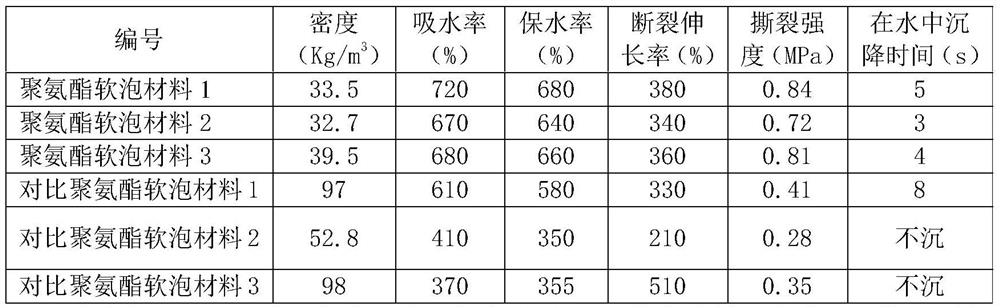

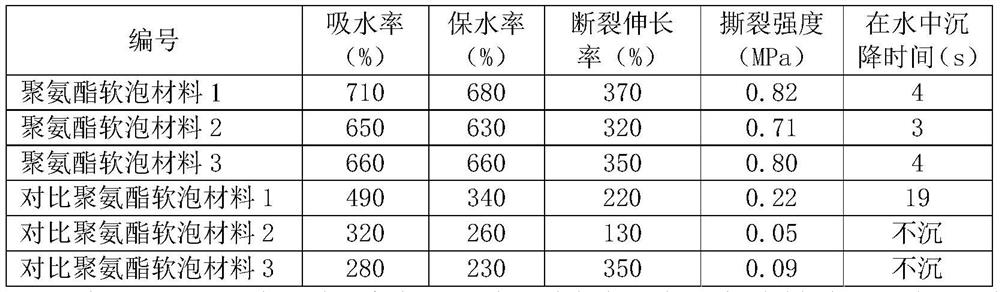

Examples

example 1

[0030] Polyurethane flexible foam material 1 is prepared by the following method:

[0031] (1) under the condition of 25 ℃, take 60 parts by weight of polyether polyol A, 25 parts by weight of polyether polyol B, 10 parts by weight of polyether polyol C and 5 parts by weight of polymer polyol D, fully stir;

[0032] (2) Under the condition of 25°C, in 100 parts by weight of the material obtained in step (1), add 3 parts by weight of water, 0.1 part by weight of catalyst A-1, 0.3 part by weight of catalyst A-33 and 1 part by weight of foam stabilizer L580, stir well;

[0033] (3) Add 50 parts by weight of modified MDI (Wannate 8019, purchased from Wanhua Chemical) to the mixture obtained in step (2) at 25°C, stir at a high speed for 3-5s, pour it into a mold for free foaming, and pass 24 hours After aging, polyurethane flexible foam material 1 was obtained.

[0034] Among them, polyether polyol A is prepared by polyaddition reaction with glycerin as the starting agent, and is...

example 2

[0036] Polyurethane flexible foam material 2 is prepared by the following method:

[0037] (1) under the condition of 22 ℃, take 65 parts by weight of polyether polyol A, 15 parts by weight of polyether polyol B, 5 parts by weight of polyether polyol C and 15 parts by weight of polymer polyol D, and stir well;

[0038] (2) Under the condition of 22°C, in 100 parts by weight of the material obtained in step (1), add 3.8 parts by weight of water, 0.1 parts by weight of catalyst A-1, 0.5 parts by weight of catalyst A-33, and 1.2 parts by weight of foam stabilizer L580 and 30 parts by weight of calcium carbonate are fully stirred;

[0039] (3) Add 60 parts by weight of modified MDI (Wannate8122B, purchased from Wanhua Chemical) to the mixture obtained in step (2) at 22°C, stir at high speed for 3-5s, pour it into the mold and foam freely, and after 24 hours After aging, polyurethane flexible foam material 2 was obtained.

[0040] The polyether polyol A is prepared by polyadditio...

example 3

[0042] Polyurethane flexible foam material 3 is prepared by the following method:

[0043](1) Under the condition of 26°C, take 65 parts by weight of polyether polyol A, 25 parts by weight of polyether polyol B and 10 parts by weight of polyether polyol C, and stir well;

[0044] (2) Under the condition of 26°C, in 100 parts by weight of the material obtained in step (1), add 3.2 parts by weight of water, 0.1 part by weight of catalyst A-1, 0.5 part by weight of catalyst A-33 and 1.0 part by weight of foam stabilizer B8285, stir well;

[0045] (3) Under the condition of 26°C, 15 parts by weight of T-80 (toluene diisocyanate, purchased from Mitsui Chemicals, Japan) and 40 parts by weight of Wannate8019 (purchased from Wanhua Chemical, modified MDI) were added to the mixture obtained in step (2). ), stirred at high speed for 3-5s, poured into the mold for free foaming, and matured for 24 hours to obtain polyurethane flexible foam material 3.

[0046] Among them, polyether poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com