Pulse tube refrigerator working condition prediction method and system based on machine learning

A pulse tube refrigerator and machine learning technology, applied in neural learning methods, special data processing applications, biological neural network models, etc., can solve problems such as insufficient monitoring of PTC operating conditions, reduce learning costs and manufacturing costs, and improve The effect of high monitoring accuracy and prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

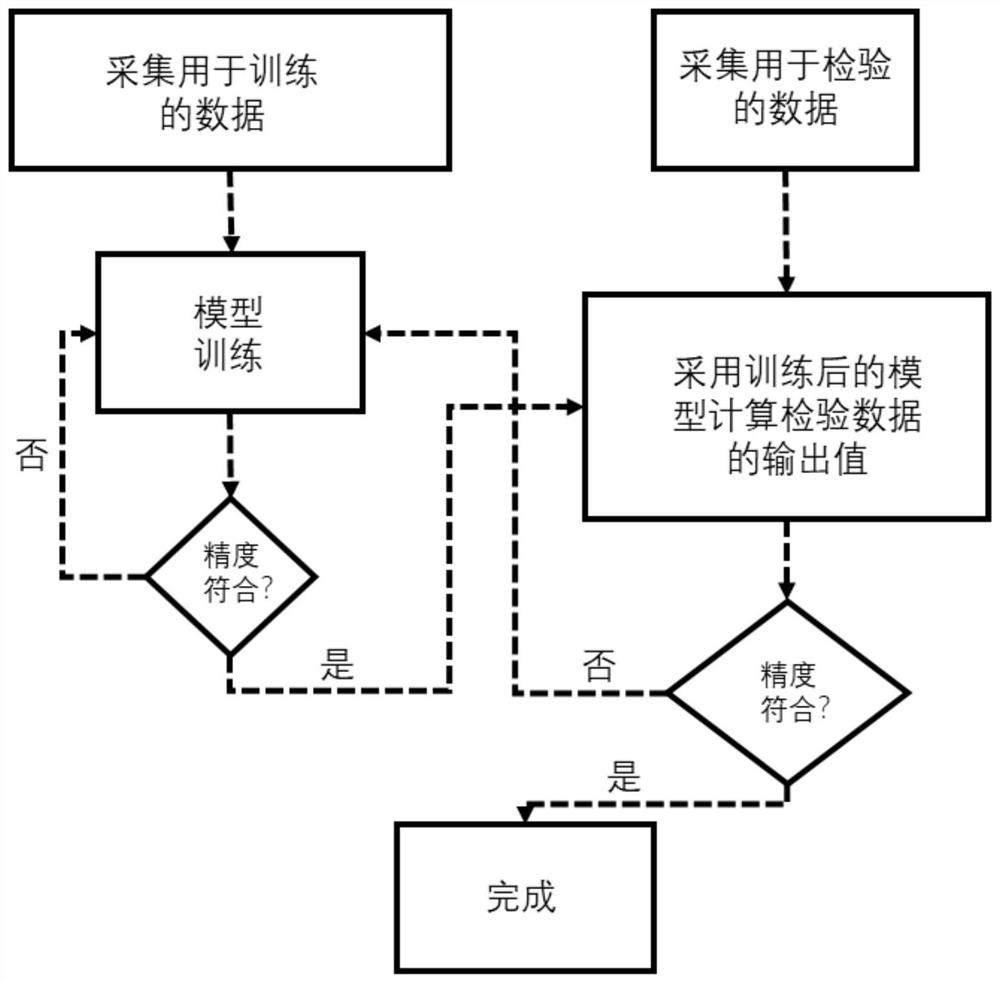

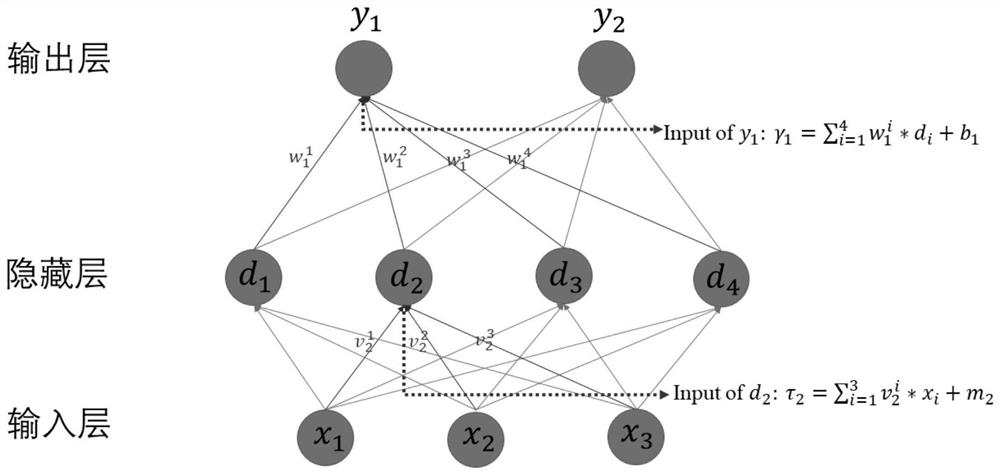

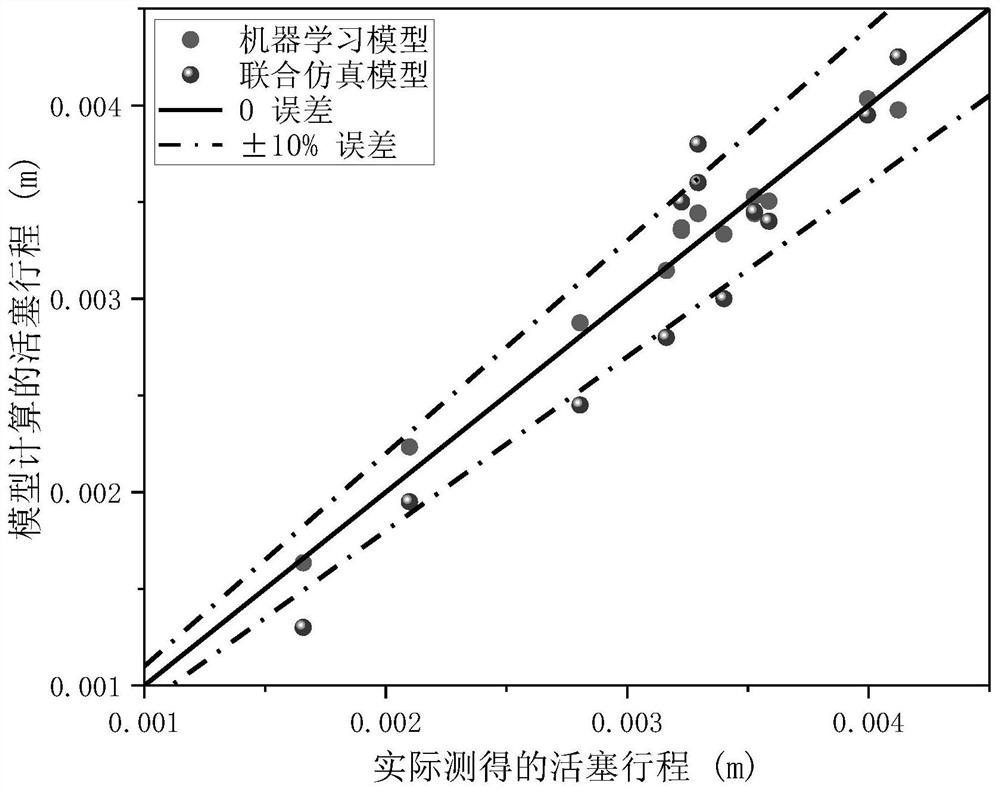

[0030] refer to figure 1 As shown, a method for predicting the working condition of a pulse tube refrigerator based on machine learning of the present invention includes the following steps: collecting the working condition parameter data of the pulse tube refrigerator during operation, and dividing the working condition parameter data into two parts: Training data and inspection data; based on the training data, the LM optimized backpropagation algorithm is used to build the working condition prediction model, and the accuracy of the working condition prediction model is continuously improved through iterative methods; the inspection data is input into the working condition prediction model, and will pass The predicted value calculated by the working condition prediction model is compared with the actual measured data to verify the accuracy of the working condition prediction model.

[0031] Specifically, the method is mainly divided into three stages: development stage, trai...

Embodiment 2

[0054] A system for predicting working conditions of a pulse tube refrigerator based on machine learning, including a data acquisition module, a learning and training module, and an inspection module. The data is divided into two parts: training data and test data; the learning and training module adopts the backpropagation algorithm of LM optimization based on the training data to build a working condition prediction model, and continuously improves the accuracy of the working condition prediction model through an iterative method; The inspection module inputs the inspection data into the working condition prediction model, and compares the predicted value calculated by the working condition prediction model with the actual measured data to verify the accuracy of the working condition prediction model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com