Pelletized coating method for improving emergence rate and seeding suitability of small and miniature grass seeds

A technology of pelletization and pelletization, which is applied in the field of pelletization coating to improve the emergence rate and suitability of sowing of small and micro grass seeds, and can solve the problems of low overall uniformity, low compressive strength, and long disintegration time , to achieve high overall uniformity, reduce seed waste, and highlight the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

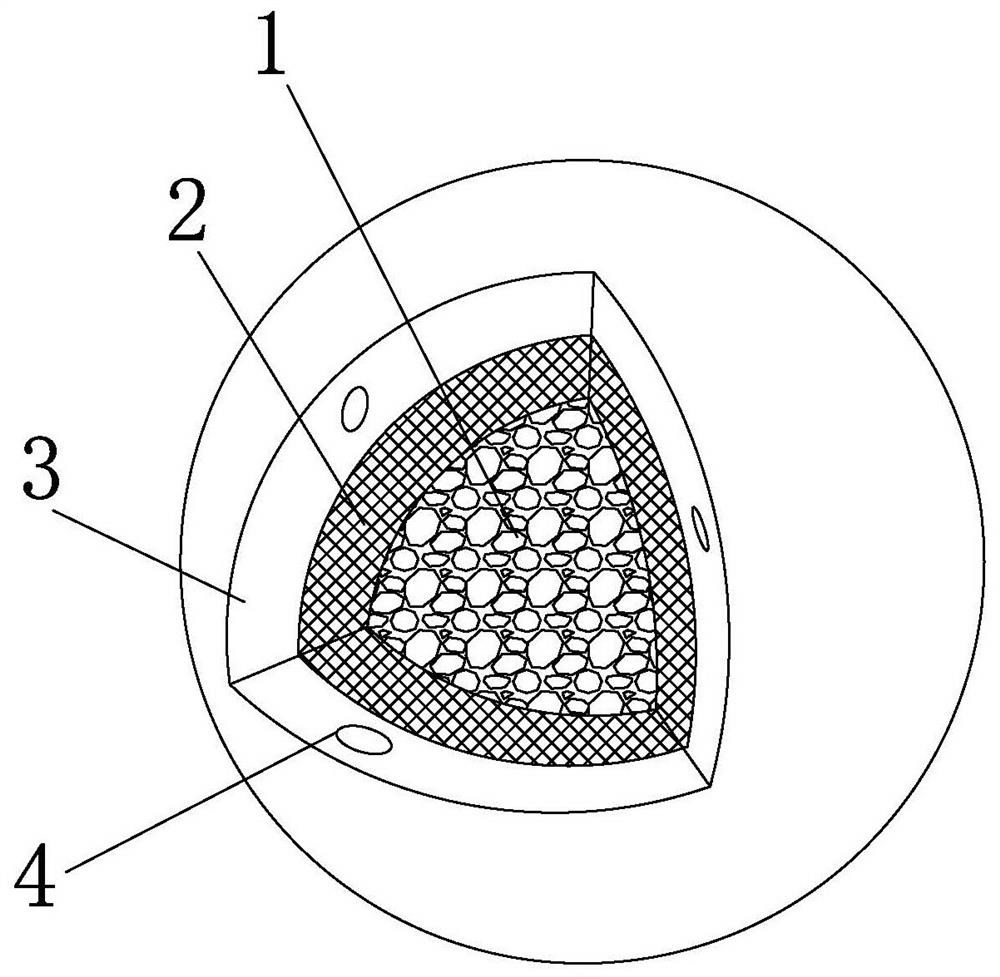

[0016] A kind of pelletized coating for improving the emergence rate and sowing performance of small and micro grass seeds, which contains 49% of pellet embryos, 49% of coating materials, and 2% of binding agent according to the weight of the components; the coating material Divided into primary coating and secondary coating. Such as figure 1 As shown, wherein the pellet embryo is composed of the pellet embryo core 1 and the primary coating 2 wrapped outside the core, the pellet embryo core 1 is divided by weight, and it contains 30% bentonite, 10% weathered coal, and 30% talcum powder , biogas residue 30%; the primary coating 2 is divided by weight, containing 20% of bentonite, and 80% of talcum powder; the pellet embryo is wrapped with a secondary coating 3, which contains 25% of bentonite , 75% talcum powder; the binder is polyvinyl formal adhesive, and each pelletized secondary coating 3 contains 3-5 grains of small grass seeds 4 . The small micrograss seed 4 is the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com