Automatic pest killing device, system and method

An automatic and pest-killing technology, applied to the device for catching or killing insects, animal traps, applications, etc., can solve the problems of environmental harm, trouble, human and animal poisoning, etc., and achieve low processing accuracy and assembly requirements, and place the place Flexibility, the effect of improving the efficiency of mouse catching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

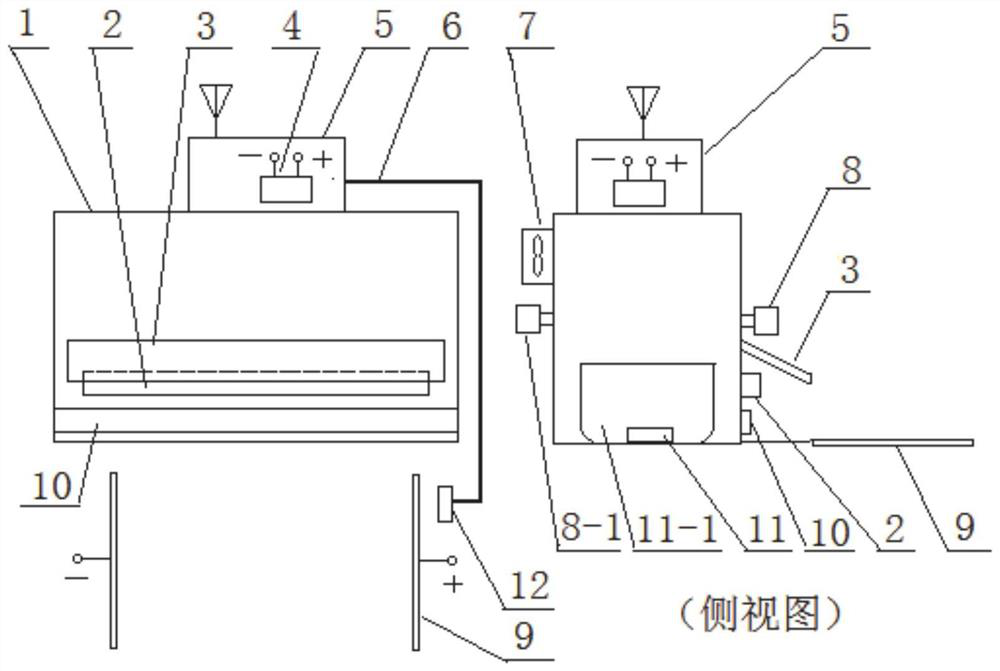

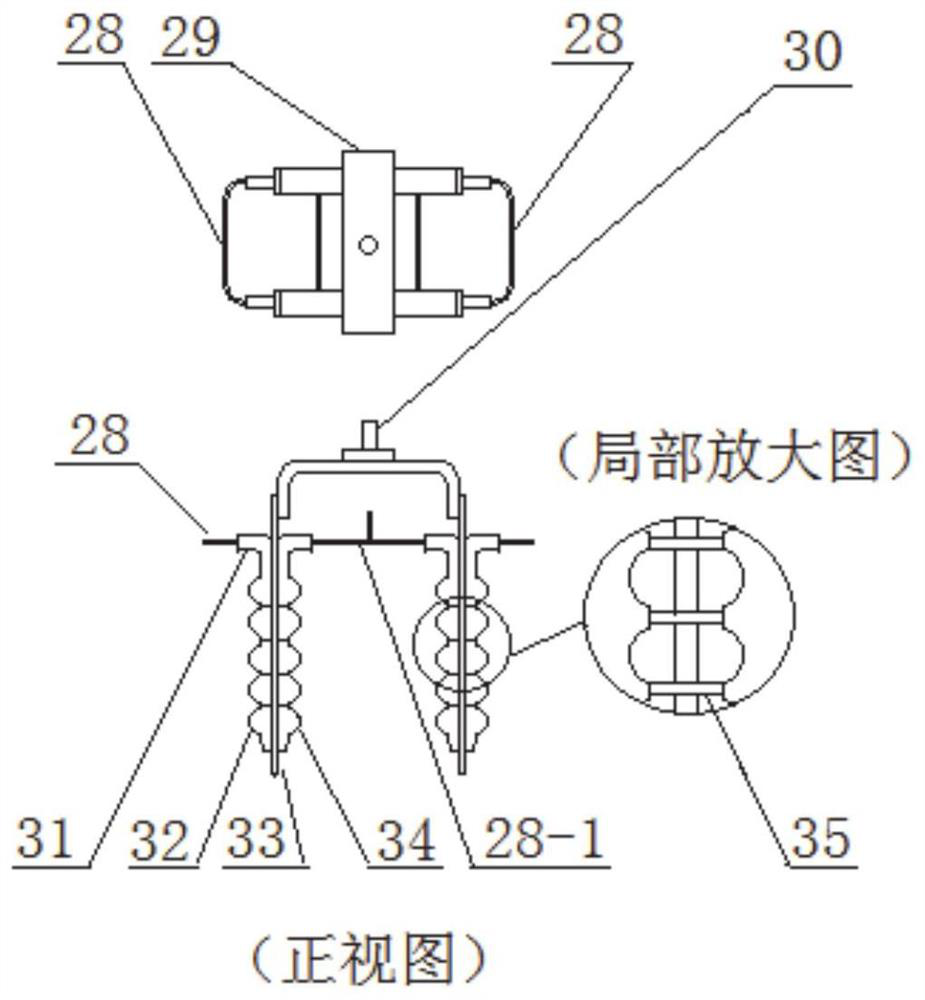

[0076] like Figure 1-7 As shown, Embodiment 1 of the present disclosure provides an automatic harm elimination device, including: a first control panel in the control box 5, a box body 1, an electrode plate 9 and a pyroelectric infrared sensor 8;

[0077] At least one spray port 2 is opened on the box body 1, and a liquid storage tank 11-1 with an opening is arranged inside the box body 1. The bottom of the liquid storage box 11-1 is provided with a first micro-controller on the first control board The ultrasonic atomizing element 11 connected to the device 44, the pyroelectric infrared sensor 8 is connected to the first microcontroller 44;

[0078] The first microcontroller 44 is connected to the electrode plate 9 through the high-voltage module 4, the electrode plate 9 includes a positive electrode plate and a negative electrode plate, and at least one spray guide plate 3 is fixed above the spray port 2, so that the spray range covers the positive electrode plate at least ...

Embodiment 2

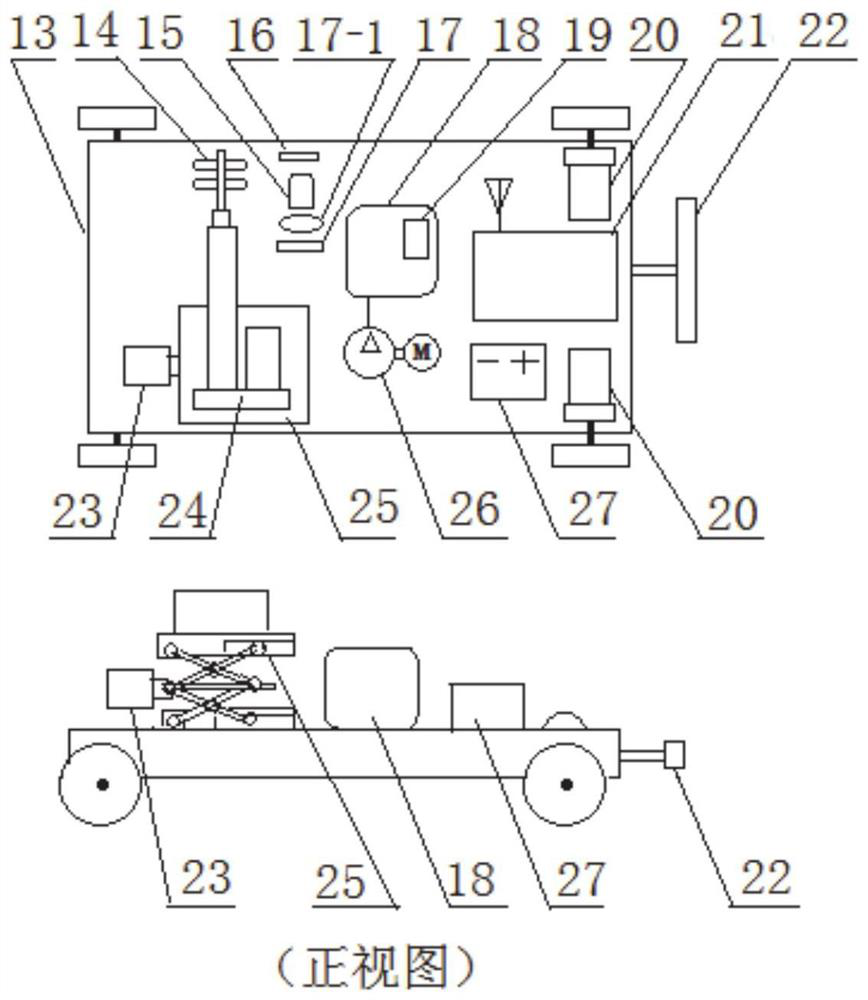

[0102] like Figure 8 As shown, Embodiment 2 of the present disclosure provides an automatic harm elimination system, including at least two sets of automatic harm elimination devices described in Embodiment 1 of the present disclosure. There is a car body guide mark on the direction, and the car body uses the on-board infrared sensor tracking module for motion navigation.

[0103] Concretely, on the ground, along the guide ropes 70 and the unit positioning marks 71 arranged along the electric shock field 72 of each unit, the head of the mouse catching vehicle 69 is provided with an infrared sensor tracking module 22 connected with the second micro-controller 52 for use To realize the navigation control of the mouse catcher along the guide rope 70.

Embodiment 3

[0105] Embodiment 3 of the present disclosure provides an automatic harm elimination method, using the automatic harm elimination device described in Embodiment 1 of the present disclosure, including the following steps:

[0106] Use the spray port of the box to spray water on the ground to form a planar water film in the area between the positive electrode plate and the negative electrode plate;

[0107] When the first control terminal receives that the mouse detected by the infrared pyroelectric sensing element enters the area of the planar water film, the positive electrode plate and the negative electrode plate are energized through the power supply module to form a planar electric field;

[0108] When the mouse enters the current field area, the distance between the feet of the mouse body is used to form a voltage difference between the feet, and the current passes through the mouse body, causing the mouse to get an electric shock. Under the action of high voltage, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com