Liquid-liquid extraction separation device and use method thereof

A separation device and extraction technology, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problems of complex structure, low efficiency, and poor applicability of extraction towers in centrifugal extractors, achieve rapid and efficient extraction and separation, increase the contact area between phases, and have multiple functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

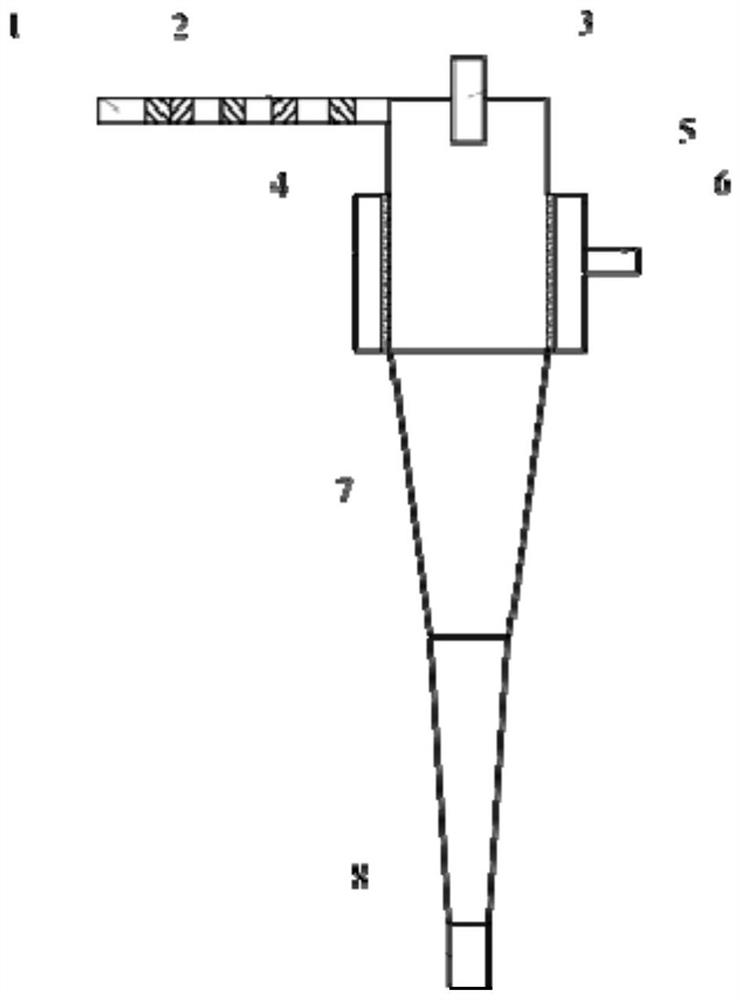

[0058] This embodiment provides a liquid-liquid extraction and separation device, the liquid-liquid extraction and separation device includes an inner casing, the upper part of the inner casing is externally connected to a liquid inlet pipe 1, and the liquid inlet pipe 1 rotates around its connection point with the inner casing , the angle between the liquid inlet pipe 1 and the axial direction of the inner casing is 10°, the extractant and the extracted liquid pass into the liquid inlet pipe 1, and inject into the inner casing obliquely upward at an incident angle of 10°, the liquid inlet pipe 1 The length is 50mm, and the diameter of the liquid inlet pipe 1 is 10mm. A light phase outlet 3 is provided on the top of the inner casing.

[0059] A static mixing part 2 is arranged inside the liquid inlet pipe 1, and the style of the static mixing part 2 is a corrugated plate. The length of the static mixer 2 is equal to the inner diameter of the liquid inlet pipe 1 .

[0060] A ...

Embodiment 2

[0066] This embodiment provides a liquid-liquid extraction and separation device, the liquid-liquid extraction and separation device includes an inner casing, the upper part of the inner casing is externally connected to a liquid inlet pipe 1, and the liquid inlet pipe 1 rotates around its connection point with the inner casing , the acute angle formed between the liquid inlet pipe 1 and the axial direction of the inner casing is 45°, the extraction agent and the extracted liquid pass into the liquid inlet pipe 1, and inject obliquely upward into the inner casing at an incident angle of 45°, and the liquid enters The length of the pipe 1 is 100 mm, and the diameter of the liquid inlet pipe 1 is 15 mm. A light phase outlet 3 is provided on the top of the inner casing.

[0067] Two static mixing parts 2 are arranged inside the liquid inlet pipe 1, and the two static mixing parts 2 are both corrugated plates. The length of the static mixing element 2 is 1.2 times the inner diame...

Embodiment 3

[0074] This embodiment provides a liquid-liquid extraction and separation device, the liquid-liquid extraction and separation device includes an inner casing, the upper part of the inner casing is externally connected to a liquid inlet pipe 1, and the liquid inlet pipe 1 is connected to the inner casing around it. When the connection point is rotated, the acute angle formed between the liquid inlet pipe 1 and the axial direction of the inner casing is 90°, the extraction agent and the extracted liquid are passed into the liquid inlet pipe 1, and injected horizontally into the inner casing, and the liquid inlet pipe The length of 1 is 150mm, and the diameter of liquid inlet pipe 1 is 20mm. A light phase outlet 3 is provided on the top of the inner casing.

[0075] Three static mixing elements 2 are arranged inside the liquid inlet pipe 1, and the patterns of the three static mixing elements 2 are corrugated plates, spiral sheets and X-shaped cross bars in sequence along the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com