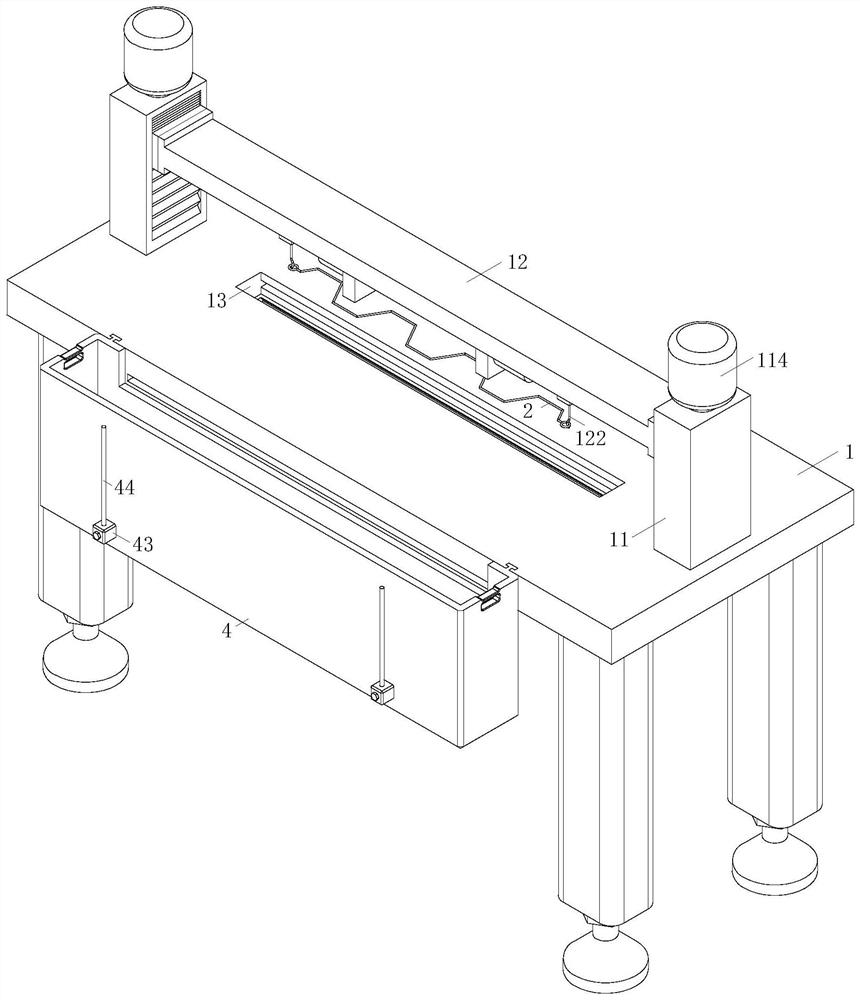

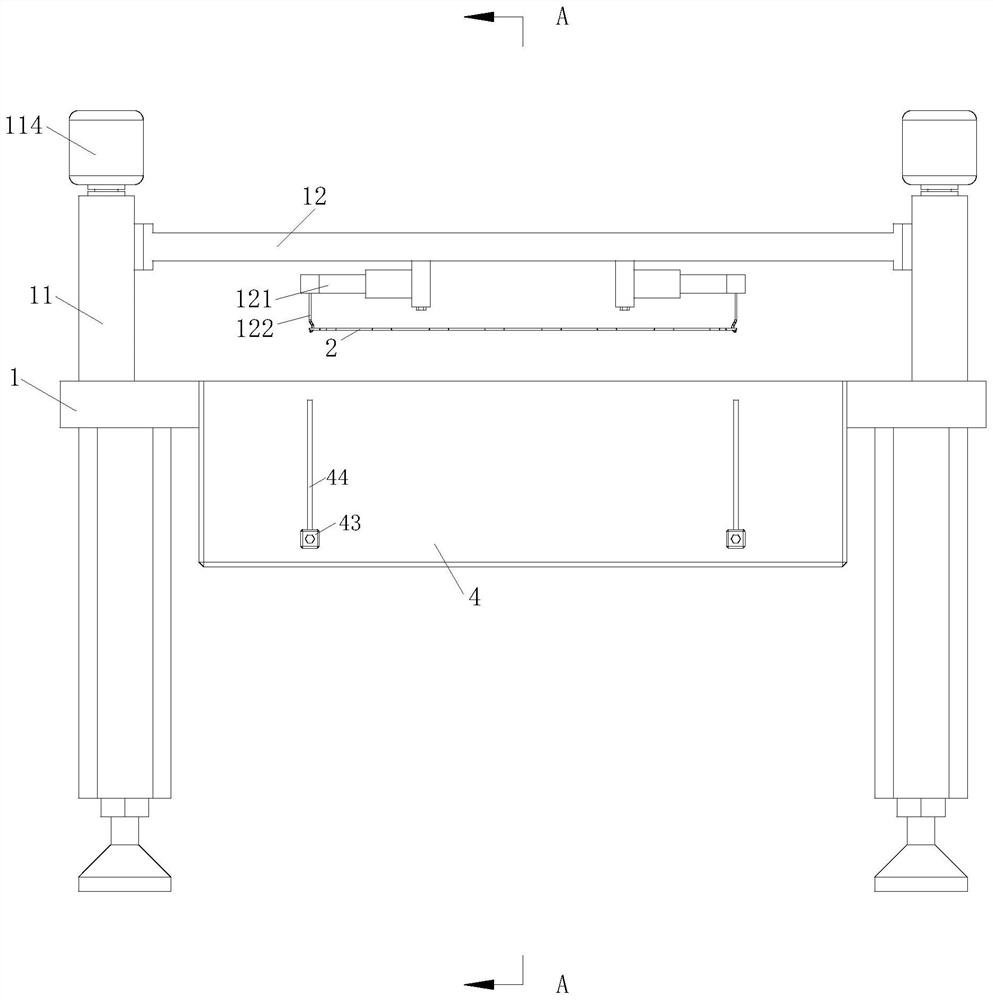

Denim processing system and processing technology

A processing system and denim technology, applied in compression water, textile and papermaking, fabric surface trimming, etc., can solve the problems of difficult control of stitching quality, affecting work efficiency, increasing production cost, etc., and achieve fast and efficient connection and separation. The effect of reducing production costs and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

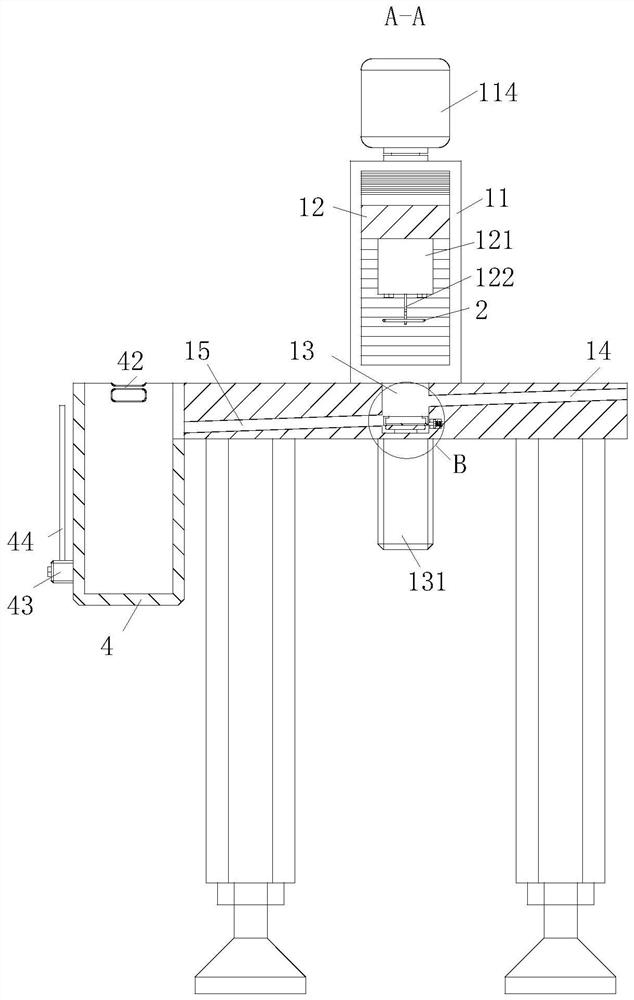

[0039] As an embodiment of the present invention, the workbench 1 is fixedly connected with a cylinder 131 near the bottom of the groove 13; the piston rod of the cylinder 131 runs through the groove 13, and the top of the cylinder 131 piston rod is fixedly connected with Push plate 132; the card slot 3 is placed on the top of the push plate 132; the first chute 14 is provided on one side of the groove 13; One end of 13 is lower than the other end, and the expansion and contraction of the piston rod of the cylinder 131 is controlled by the controller; when working, by setting the first chute 14, it is convenient to place a plurality of card slots 3, which is convenient for automatic loading of the card slots 3, and improves denim processing. Efficiency; when loading the card slot 3, select the appropriate card slot 3 according to the denim production requirements, and put the card slot 3 from the side with the higher opening of the first chute 14, and the card slot 3 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com