Titanium-containing magnesium fluxed pellet and manufacturing method thereof

A fluxing and pelletizing technology, which is applied in the field of titanium-containing magnesia fluxing pellets and its manufacturing, to achieve the effects of solving roasting and bonding and improving metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

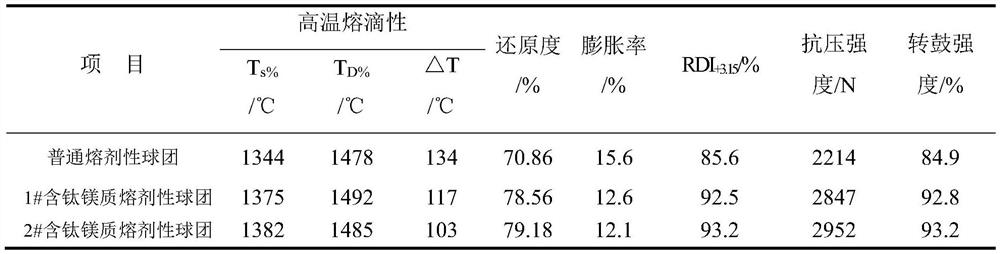

Examples

Embodiment 1

[0045] In this embodiment, the high-basicity sintered ore return is used as the pelletizing core to produce titanium-containing magnesium flux pellets with inner and outer layers and double alkalinity. The manufacturing process is as follows:

[0046] Iron concentrate, binder A and light pyroligne powder form primary mixture, wherein the mass fraction of iron concentrate powder is 95.8%; binder A is sodium carboxymethyl cellulose, and its mass fraction is 1.2%; The mass fraction of burnt magnesium powder is 3%; the mixture is made by adding quicklime to the initial mixture, and the amount of quicklime is adjusted so that the alkalinity of the mixture is 0.9; the mass fraction of MgO in the mixture is 2.1%.

[0047] The iron concentrate is composed of ilmenite concentrate A and high-iron and low-silicon iron concentrate. The mass ratio of ilmenite concentrate A to high-iron and low-silicon iron concentrate is 25:75; the total iron grade of the high-iron and low-silicon iron con...

Embodiment 2

[0053] In this embodiment, the high-basicity sintered ore return is used as the pelletizing core to produce titanium-containing magnesium flux pellets with inner and outer layers and double alkalinity. The specific manufacturing process is as follows:

[0054] Iron ore concentrate, binder A and burntite powder are used to form the initial mixture, wherein the mass fraction of iron concentrate is 93.5%; binder A is bentonite, and its mass fraction is 2%; the mass fraction of burntite powder is Fraction 4.5%; Add quicklime to the primary mixture to form a mixture, adjust the amount of quicklime added so that the alkalinity of the mixture is 1; the MgO mass fraction of the mixture is 2.4%.

[0055] The iron concentrate is composed of ilmenite concentrate A and high-iron and low-silicon iron concentrate. The mass ratio of ilmenite concentrate A to high-iron and low-silicon iron concentrate is 40:60; the total iron grade of the high-iron and low-silicon iron concentrate is 68 %, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com