Flow guide full-wrapping type oiling roller for chemical fiber production and processing

An oil roller and chemical fiber technology, which is applied in the field of chemical fiber production and processing, can solve the problems of decreased quality of chemical fiber, poor oiling effect on the side of chemical fiber, uneven oiling of chemical fiber, etc., so as to reduce friction, prevent breakage and damage, and improve oiling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

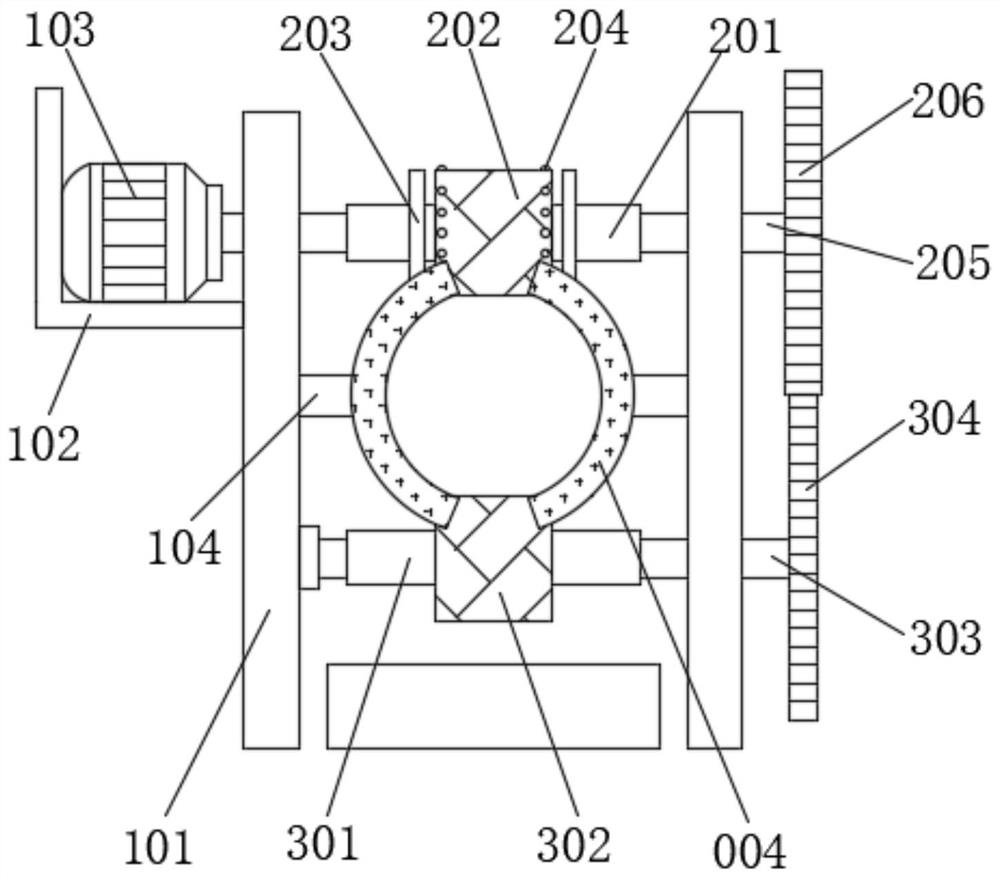

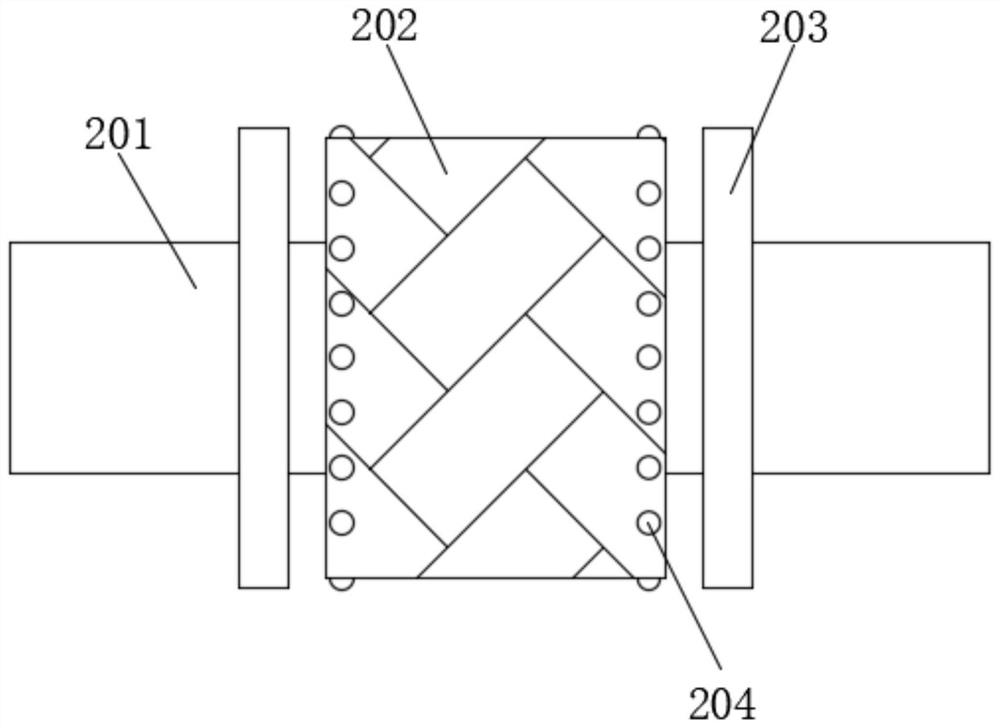

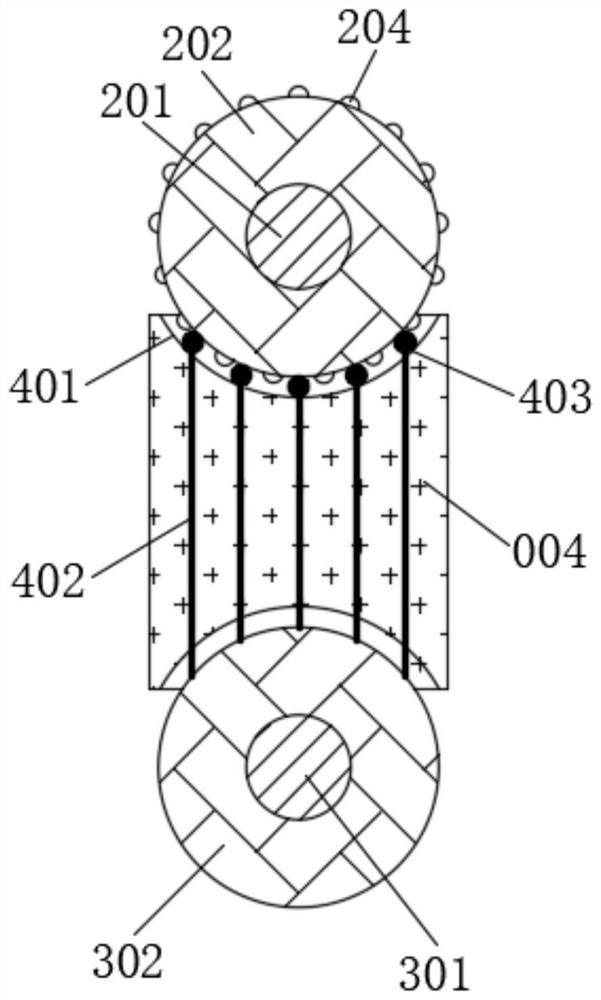

[0036] see Figure 1-6 , a diversion all-inclusive oiling roller for chemical fiber production and processing, including two supporting vertical plates 101 arranged in parallel, between the two supporting vertical plates 101, a main rotation oiling roller body and a main rotating oiling roller are arranged. The body is matched with the oil roller body of the slave rotation. The oil roller body of the main rotation is located above the oil roller body of the slave rotation. The oil roller body of the main rotation includes the main rotation roller 201, and the outer wall of the main rotation roller 201 is fixed. There is a main rotation upper oil cylinder brush 202, the outer walls of the main rotation upper oil cylinder brush 202 are fixedly connected with a plurality of extrusion bumps 204 which are evenly distributed in a ring shape, and the two ends of the main rotation roller 201 are fixedly connected with The main rotating shaft 205, the oil roller body from the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com