Small automatic loose sand barreling machine

A barrel loading machine and automatic technology, which is applied in the direction of motor vehicles, storage devices, loading/unloading, etc., can solve the problems of different convenience and work efficiency of sand removal devices, and achieve ingenious structural settings, high work efficiency, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

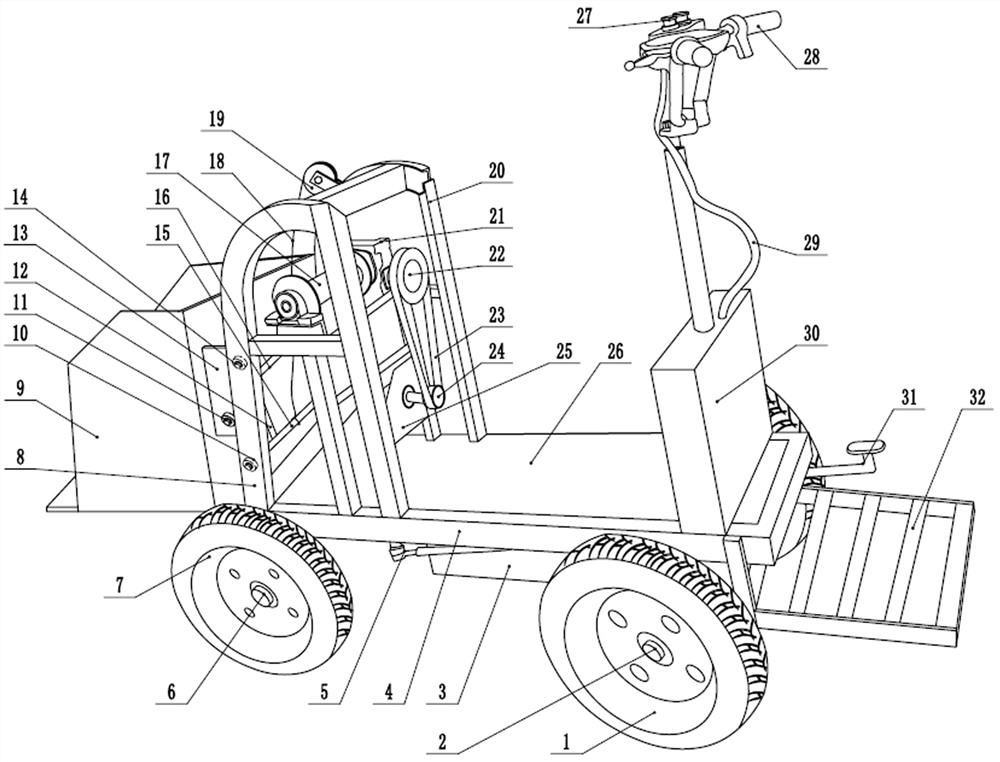

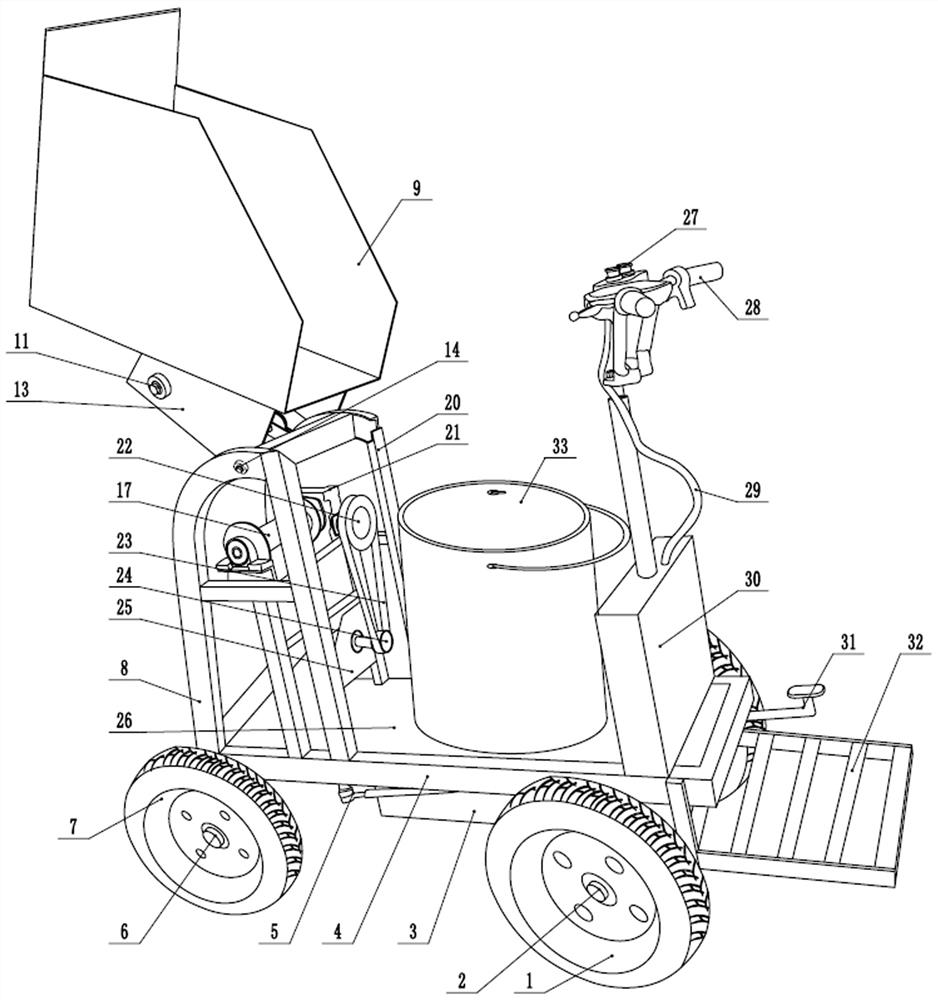

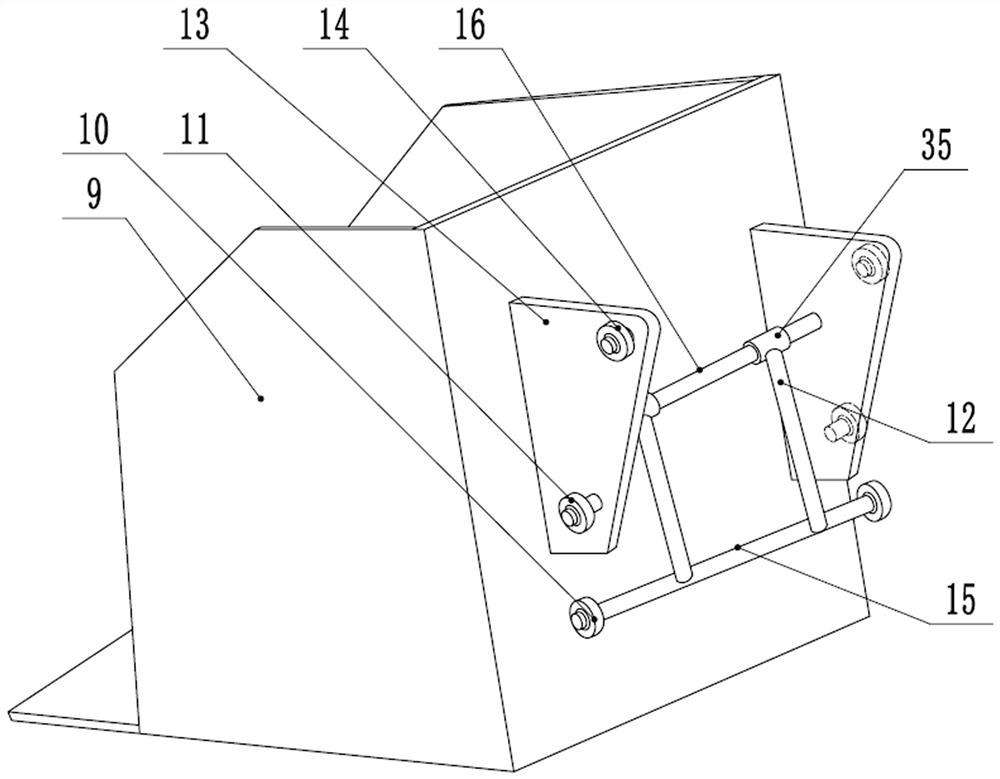

[0027] A small automatic loose sand barreling machine, which includes a frame 4 and a bucket 9, the lower part of the front end and the rear end of the frame 4 are correspondingly installed with a front axle 6 with a front wheel 7 and a rear wheel 1 The electric rear axle 2; the upper front end of the vehicle frame 4 is provided with a bracket 20, a slide rail 8 is respectively provided on both sides of the front end of the bracket 20, and a slide groove 34 is respectively provided on the opposite sides of the two slide rails 8; A fixed pulley 19 is installed on the upper front end of the bracket 20; a vertically arranged supporting connecting plate 13 is respectively arranged on both sides of the back of the bucket 9, and a supporting connecting rod 16 is fixedly connected between the two supporting connecting plates 13, Connecting sleeve 35 is sleeved on the supporting connecting rod 16, and connecting sleeve 35 is fixedly connected with mounting rod 15 by connecting rod 12. ...

Embodiment 2

[0029] A small automatic loose sand barreling machine, which includes a frame 4 and a bucket 9, the lower part of the front end and the rear end of the frame 4 are correspondingly installed with a front axle 6 with a front wheel 7 and a rear wheel 1 The electric rear axle 2; the upper front end of the vehicle frame 4 is provided with a bracket 20, a slide rail 8 is respectively provided on both sides of the front end of the bracket 20, and a slide groove 34 is respectively provided on the opposite sides of the two slide rails 8; A fixed pulley 19 is installed on the upper front end of the bracket 20; a vertically arranged supporting connecting plate 13 is respectively arranged on both sides of the back of the bucket 9, and a supporting connecting rod 16 is fixedly connected between the two supporting connecting plates 13, Connecting sleeve 35 is sleeved on the supporting connecting rod 16, and connecting sleeve 35 is fixedly connected with mounting rod 15 by connecting rod 12. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap