Plunger

A plunger and flow column technology, which is applied in the field of natural gas and oil exploitation, can solve the problems of the plunger not being able to go down, lower lifting efficiency, and increased plunger leakage, and achieve the goals of reduced resistance, high lifting efficiency, and reduced fluid leakage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

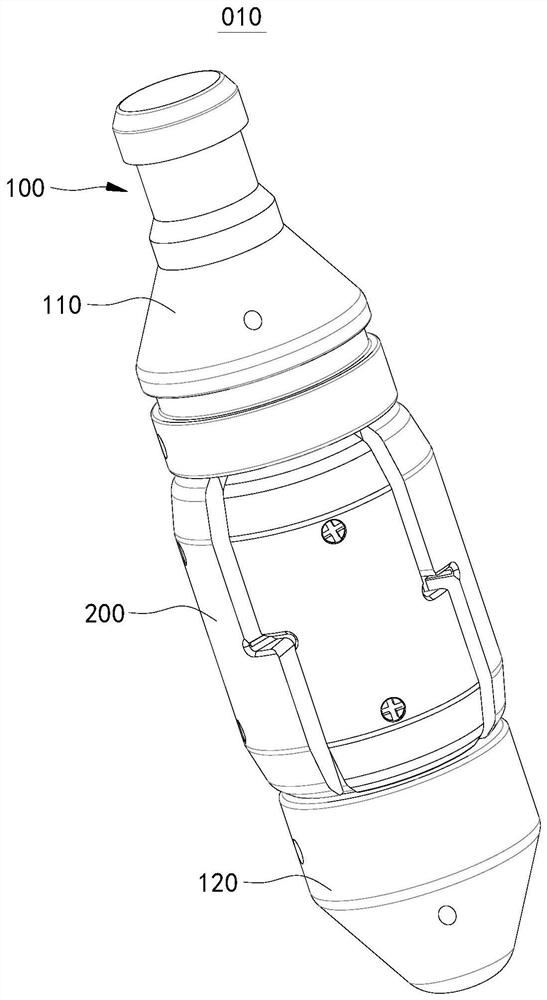

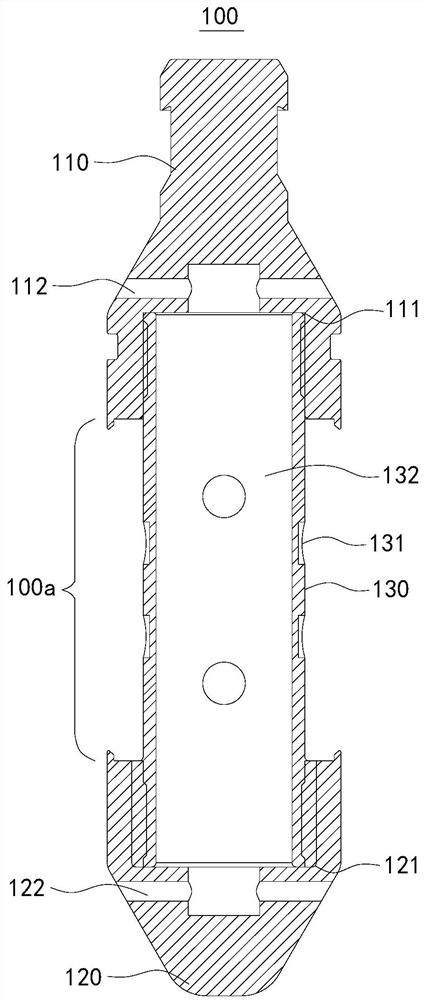

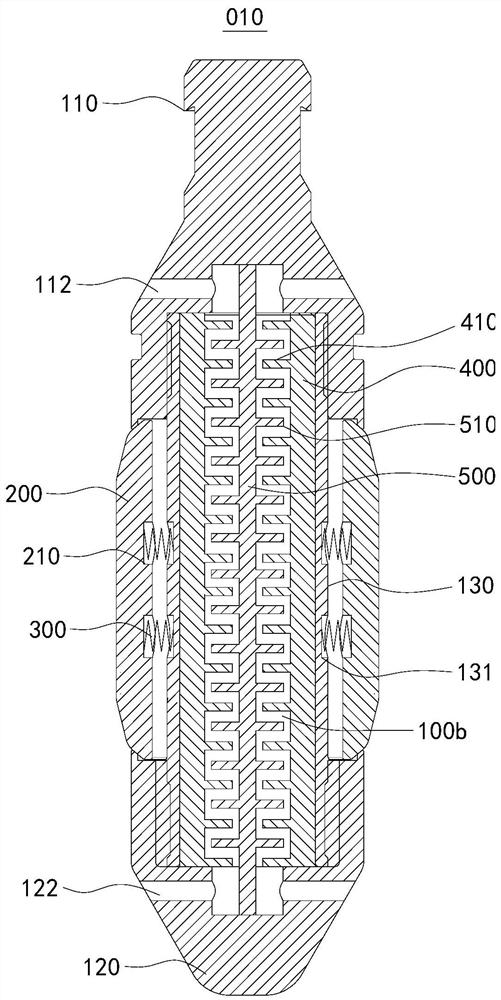

[0039] figure 1 A schematic diagram of the external structure of the plunger 010 provided in this embodiment. figure 2 A schematic structural diagram of the core body 100 in the plunger 010 provided in the embodiment of the present application. image 3 A schematic cross-sectional structure diagram of the plunger 010 provided in this embodiment. Please refer to figure 1 and figure 2, in this embodiment, the plunger 010 includes a core body 100 , a sealing gasket 200 , a first elastic reset member 300 , an outer restrictor tube 400 and an inner restrictor column 500 .

[0040] The core body 100 includes an upper end 110 , a lower end 120 and a core tube 130 . One end of the upper end 110 is provided with an upper connecting hole 111 , and an internal thread is arranged in the upper connecting hole 111 . An upper fluid hole 112 is defined on the side of the upper end 110 . The upper fluid hole 112 extends radially and communicates with the upper connecting hole 111 and th...

Embodiment 2

[0049] Figure 5 A schematic cross-sectional structure diagram of the plunger 010 provided in this embodiment. The plunger 010 provided in this embodiment is basically the same as that described in Embodiment 1, except that, in this embodiment, one of the inner restrictor column 500 and the outer restrictor tube 400 is fixedly arranged, and the other Axially movable setting.

[0050] Specifically, in this embodiment, the inner restrictor column 500 can be axially movable, and the outer restrictor tube 400 is fixedly arranged. The outer restrictor tube 400 is fixedly arranged in the manner described in Embodiment 1.

[0051] When the plunger 010 goes down in the shut-in state, if the fluid resistance is too large, it will push the inner restrictor column 500 to move axially, so that the inner restrictor ring 510 and the outer restrictor ring 410 are in contact, and the inner restrictor post 500 and the outer restrictor ring 410 are in contact. The tortuous flow channel 100b ...

Embodiment 3

[0055] Figure 6 A schematic cross-sectional structure diagram of the plunger 010 provided in this embodiment. The plunger 010 provided in this embodiment is basically the same as that described in Embodiment 1, except that, in this embodiment, one of the inner restrictor column 500 and the outer restrictor tube 400 is fixedly arranged, and the other Axially adjustable position setting.

[0056] Specifically, in this embodiment, the position of the inner restrictor column 500 can be adjusted axially, and the outer restrictor tube 400 is fixedly arranged. The outer restrictor tube 400 is fixedly arranged in the manner described in Embodiment 1.

[0057] The size of the gap between the inner restrictor ring 510 and the outer restrictor ring 410 can be adjusted freely by adjusting the axial position of the inner restrictor post 500 . The size of the gap between the inner restrictor ring 510 and the outer restrictor ring 410 is adjusted according to the energy condition at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com