High-frequency-response infinite-stiffness intelligent supporting rod piece based on semi-active control method

A support rod and high-frequency response technology, which is applied in the direction of vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problems of large amount of interaction with the upper controller, large mass of support rod system truss, and complex system control loop. , to achieve the effects of not being affected by external temperature changes, compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

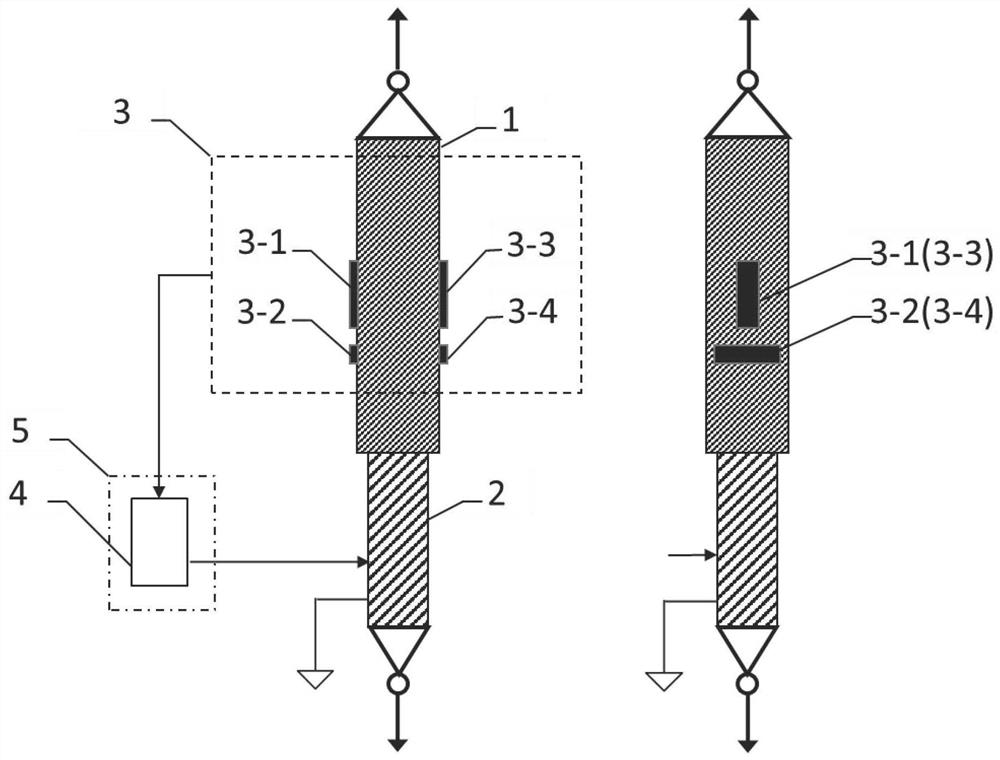

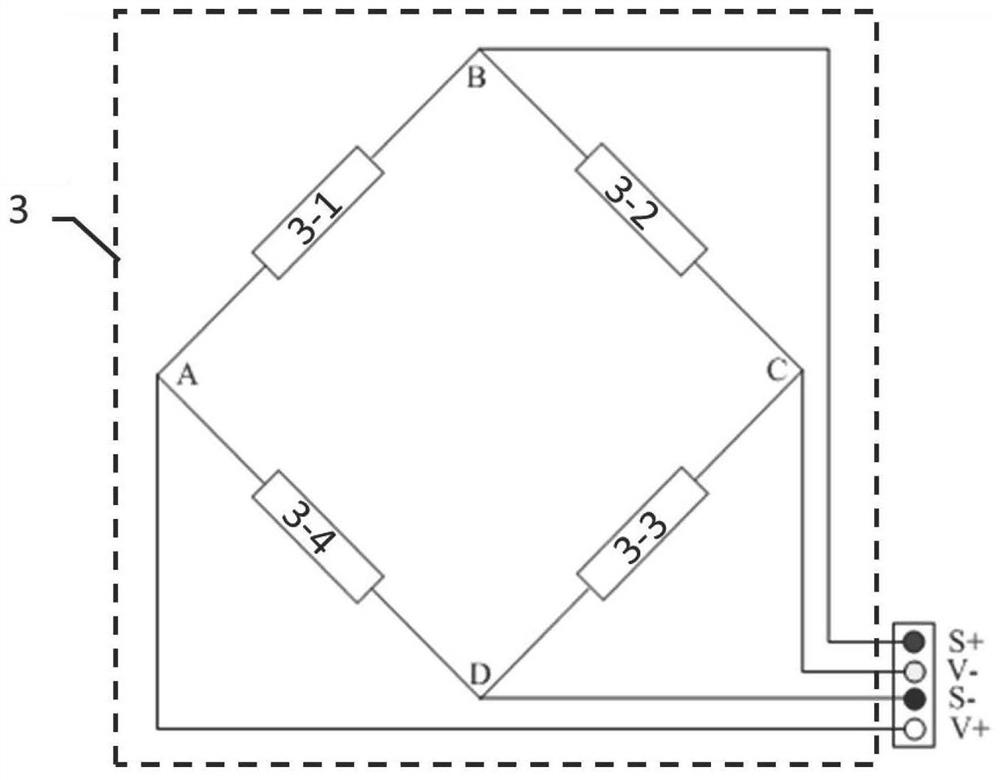

[0022] For two-force rods with two ends hinged, the commonly used support rod 1 of the present invention is installed in series with the series rod 2 made of electrostrictive material, and is measured by the upper strain measurement sensor group 3 pasted on the commonly used support rod 1 The force deformation of the commonly used strut member 1, because the strain measurement sensor group 3 is composed of the first strain sensor 3-1, the second strain sensor 3-2, the third strain sensor 3-3, and the fourth strain sensor 3-4 The Wheatstone full-bridge strain circuit is formed to ensure that the measurement results are basically not affected by changes in the external temperature environment.

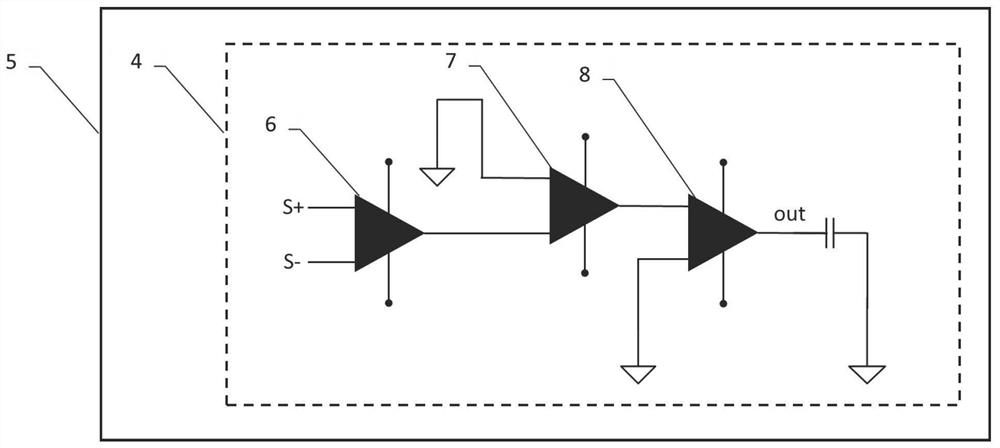

[0023] The highly integrated analog controller 4 is installed in the miniature constant temperature control box 5, and is composed of a differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com