Battery slurry stability detection method and device

A detection method and stability technology, applied in the field of battery slurry stability detection, can solve the problems of more than one hour, long solid content test time, high labor cost, etc., to achieve simple operation, avoid battery slurry settlement, and shorten the test the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

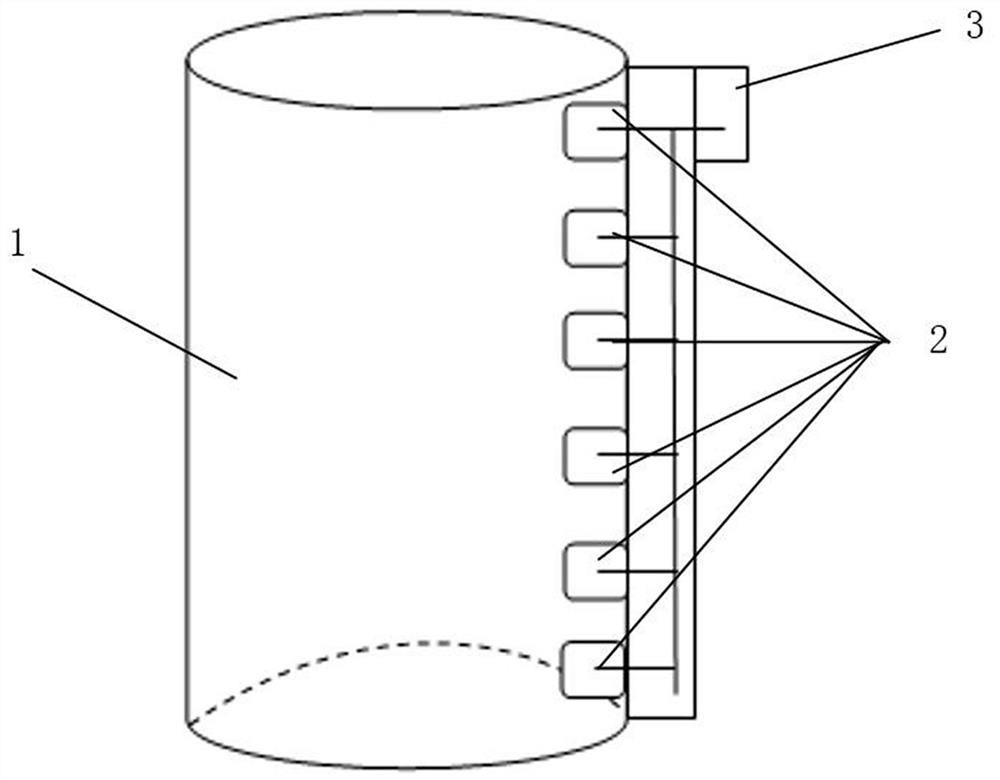

[0052] This embodiment provides a battery slurry stability detection device, such as figure 1 As shown, the device includes a container 1 for battery slurry, a detection unit 2 and a controller 3, the detection unit 2 is arranged on the inner side wall of the container 1, and the controller 3 communicates with the detection unit 2 to receive the detection unit 2 The values transmitted and calculated to obtain the solid content of each test point at different time points. In this embodiment, the controller 3 can be a centralized or distributed controller. For example, the controller 3 can be a single single-chip microcomputer, or it can be composed of distributed multi-block single-chip microcomputers. The control program can be run in the single-chip microcomputers, and then The detection unit 2 is controlled to realize its function.

[0053] The detection unit 2 is a pressure sensor or a pressure sensor, which can be selected according to actual needs. The detection unit ...

Embodiment 2

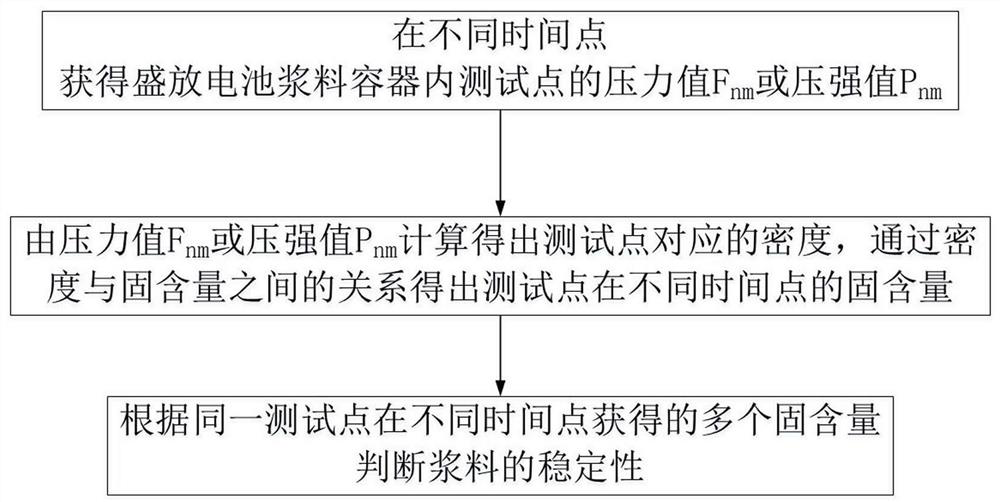

[0056] Such as figure 2 As shown, this embodiment provides a battery slurry stability testing method, which is applied to the battery slurry stability testing device provided in Example 1. The method provided in this example mainly includes the following steps:

[0057] Obtain the pressure value F of at least one test point below the liquid level of the battery slurry in the battery slurry container at different time points nm or pressure value P nm , where, n is the test point label, m is the time point label;

[0058] When the test point is one, the test point is located above the liquid bottom of the battery slurry;

[0059] By pressure value F nm or pressure value P nm Calculate the density corresponding to the test point, and obtain the solid content of the test point at different time points through the relationship between density and solid content;

[0060] The stability of the battery slurry was judged based on multiple solid contents obtained at different time ...

Embodiment 4

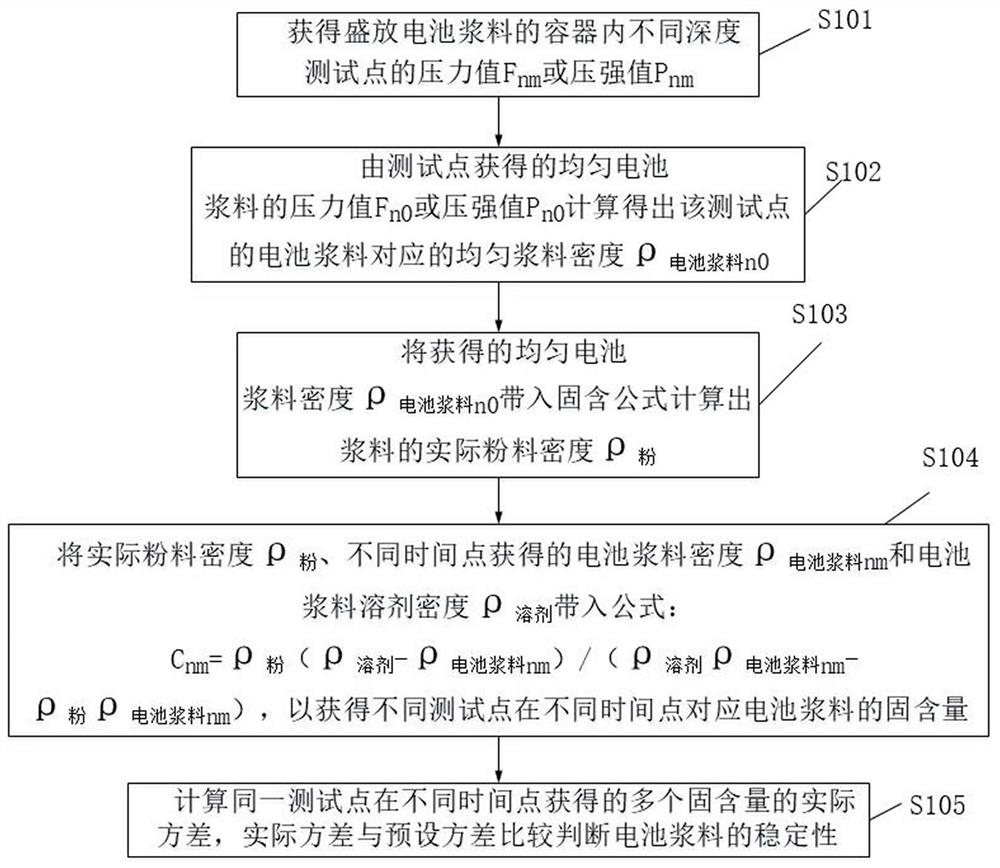

[0131] This embodiment provides a battery slurry stability testing method, which is applied to the battery slurry stability testing device provided in Example 1. The method provided in this example mainly includes the following steps:

[0132] Obtain the pressure value F of at least one test point below the liquid level of the battery slurry in the battery slurry container at different time points nm or pressure value P nm , where, n is the test point label, m is the time point label;

[0133] When the test point is one, the test point is located above the liquid bottom of the battery slurry;

[0134] By pressure value F nm or pressure value P nm Calculate the density corresponding to the test point, and obtain the solid content of the test point at different time points through the relationship between density and solid content;

[0135] The stability of the battery slurry was judged based on multiple solid contents obtained at different time points at the same test point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com