Calibration device for stress optical coefficient of transparent material

A technology of transparent materials and optical coefficients, applied in measuring devices, analyzing materials, adopting mechanical devices, etc., can solve problems such as large calibration errors, complicated calibration devices, and limited use scenarios, and achieve the effect of compact structure and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

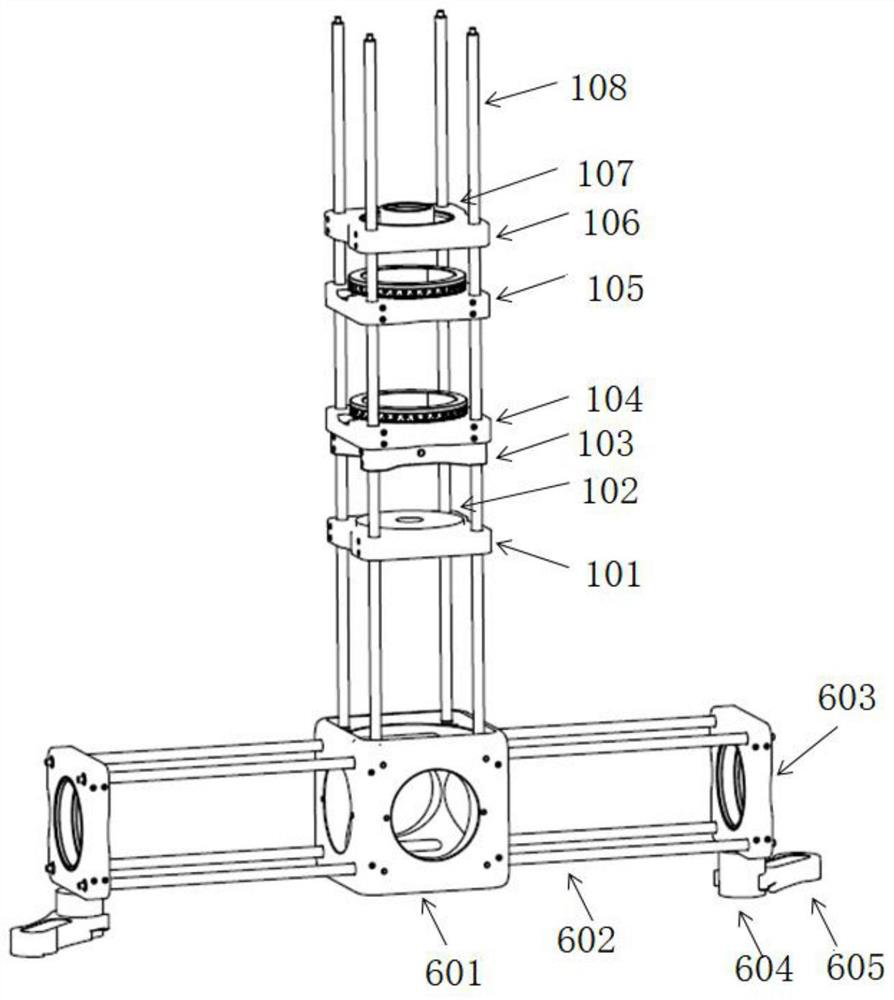

[0067] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

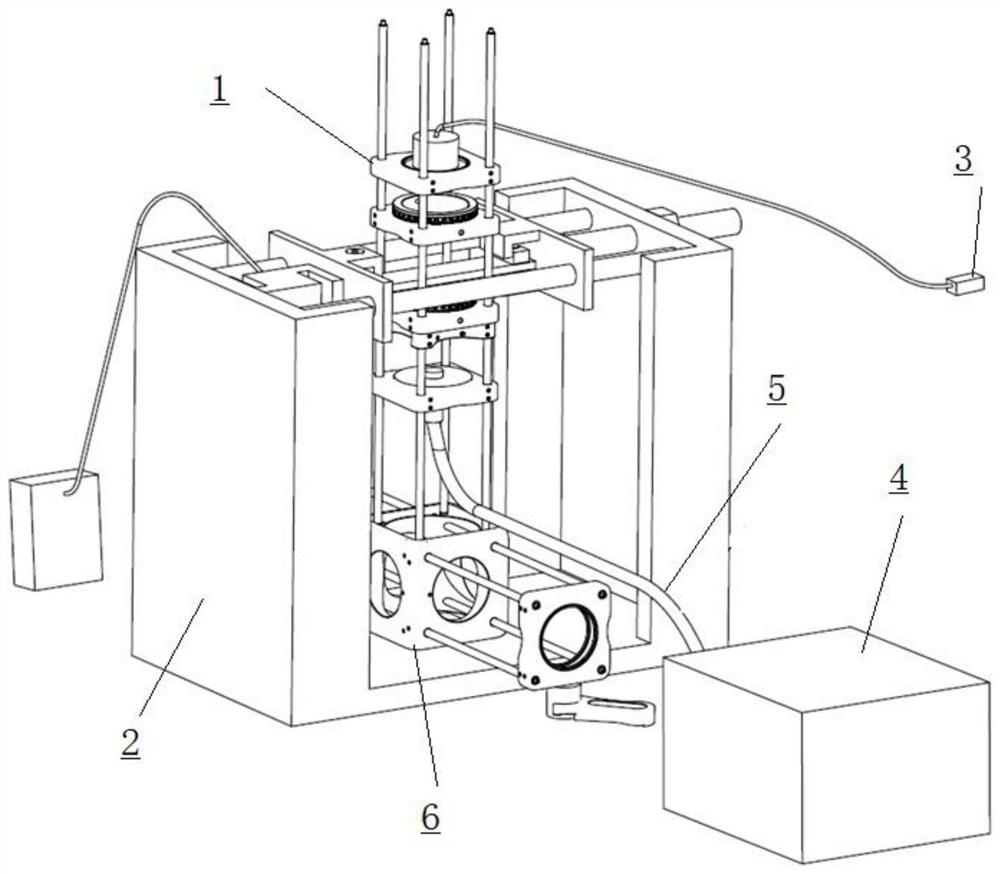

[0068] A specific embodiment of the present invention discloses a calibration device for stress optical coefficients of transparent materials. Such as figure 1 As shown, the device includes:

[0069] The tension mechanism 2 includes a sample slot for placing the standard piece of transparent material to be tested, and is used to apply axial pulling forces of different sizes to the standard piece of transparent material to be tested. Specifically, the transparent material standard to be tested refers to an isotropic material with no internal stress inside and isotropic in terms of optical per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com