Device and method for removing pollution particles on surface of mask protective film

A surface pollution and protective film technology, which is applied in the field of mask protective film surface pollution particle removal device, can solve the problems of exacerbating the risk of protective film rupture and unfavorable particle desorption, so as to prolong the normal service life, reduce the risk of membrane rupture, The effect of delaying relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

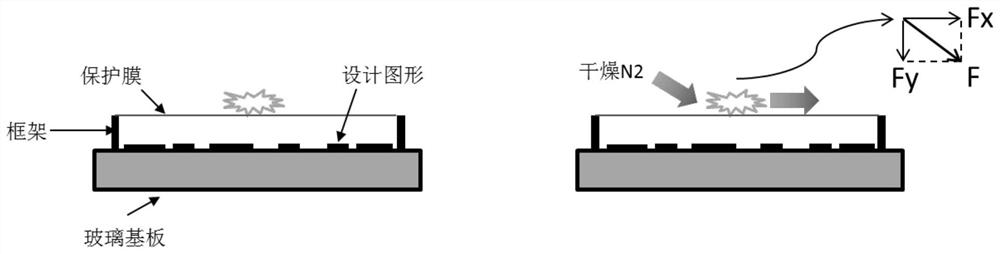

[0027] Figure 4 It is a schematic diagram of an embodiment of the device for removing contamination particles on the surface of the mask protection film of the present invention. The device for removing contamination particles on the surface of the mask protection film is disposed above the reticle carrying platform 500 .

[0028] The device for removing contamination particles on the surface of the mask protection film includes a charge generating device 100 and a charge eliminating device 102 . The charge generating device 100 can generate a large amount of charged airflow 101 , for example, the airflow is negatively charged to form a flow of negative oxygen ions with strong electron affinity. The direction of the airflow 101 is parallel to the reticle stage 500 . The generation of electric charge in gas, in addition to electrons attaching to the surface of gas molecules to form electronegative gas, can also be generated by the ionization of gas molecules themselves or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com