Device and method for diagnostic testing of COVID-19, viruses, antibodies and markers

A biodetector, bioassay technology, applied in biochemical equipment and methods, chemical instruments and methods, and microbial determination/inspection, etc., can solve the problems of analysis delay, low sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

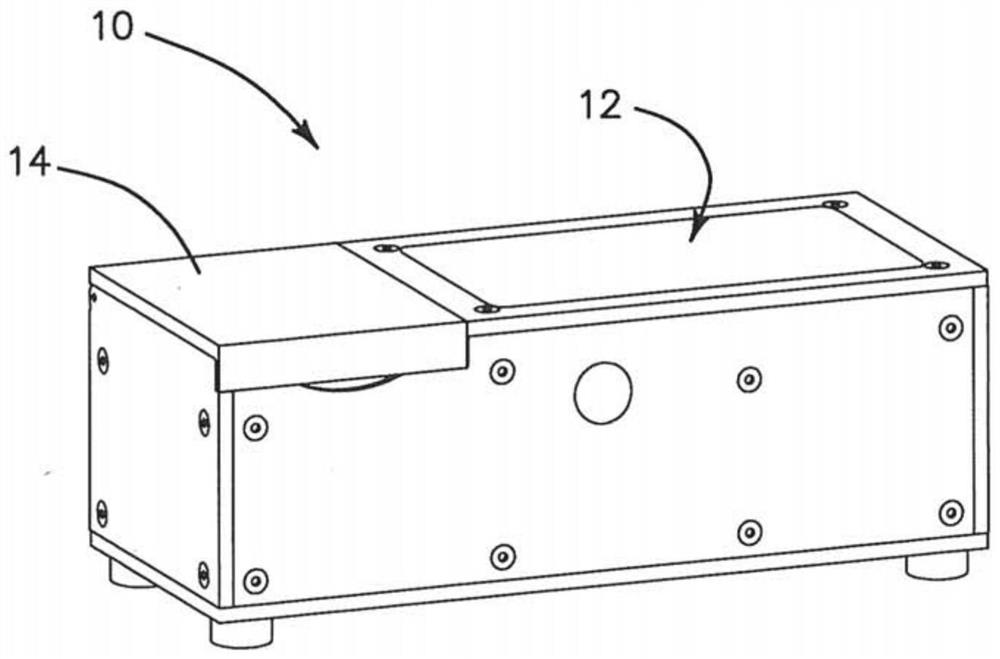

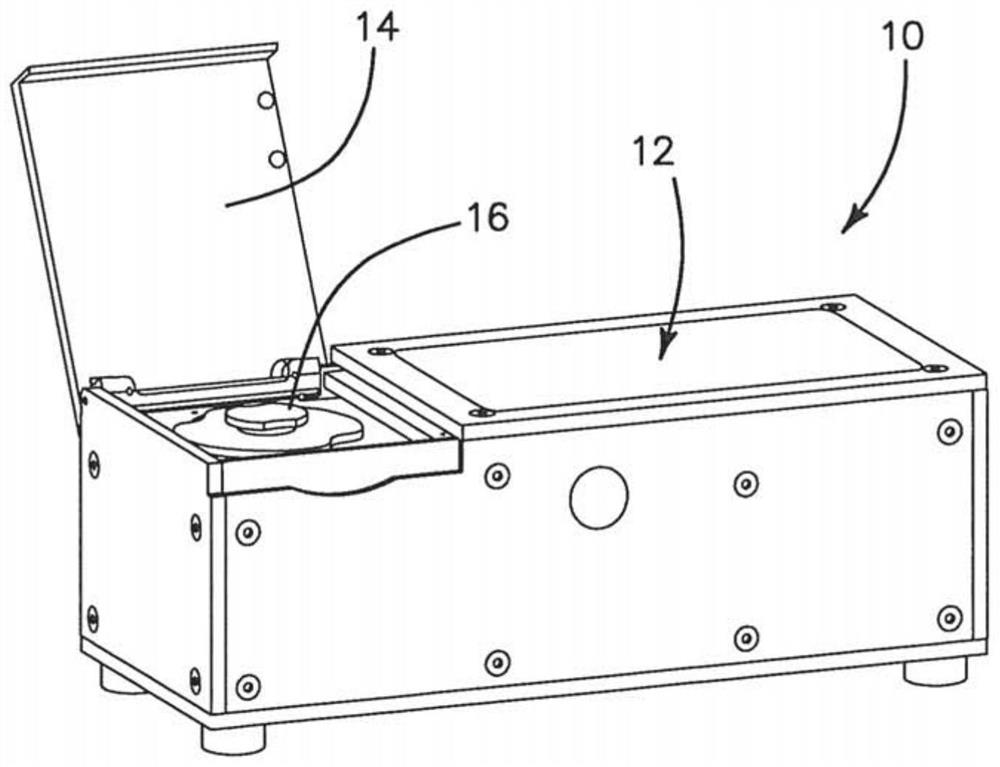

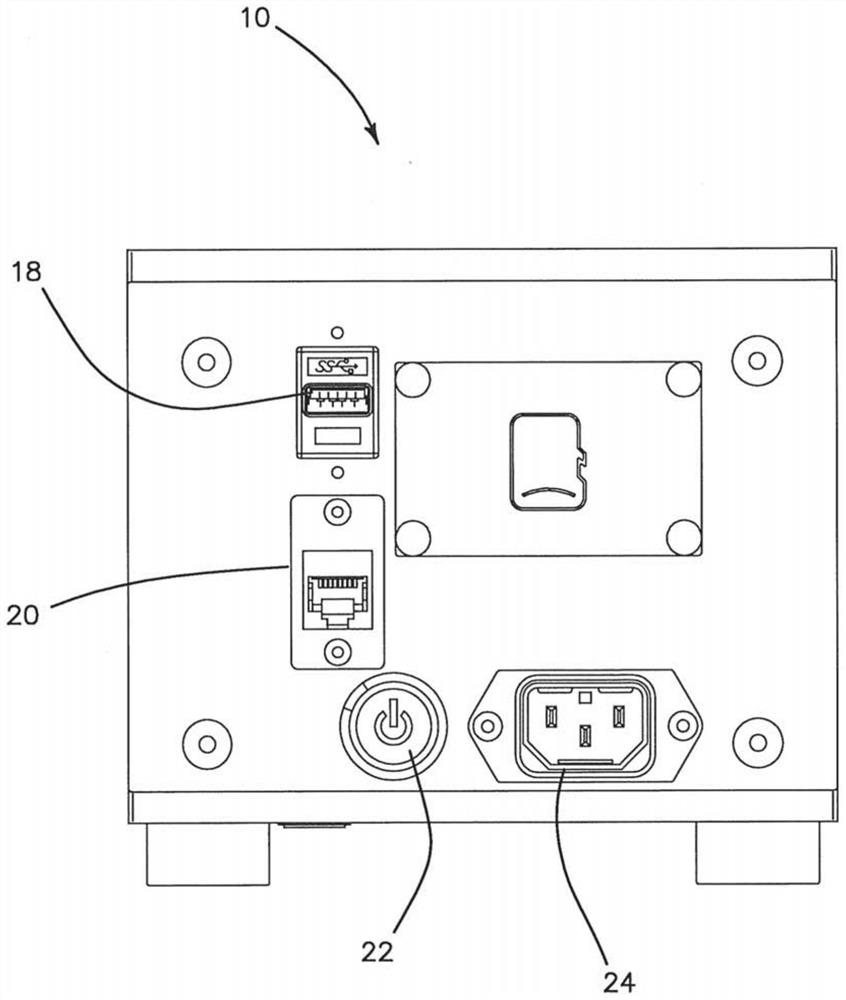

[0106] The device of the illustrated embodiment includes a central unit that includes electronic components, cameras, optical components, digital data collection components, and communication components to communicate with a cloud-based expert diagnostic server via the Internet, and to provide information on Covid-19 and other viruses or Electromechanical components required for on-site portable diagnostic testing of bacterial infections. The same hub unit supports at least three different microfluidic discs 68 (CD) for diagnostic assays or detection, i.e., microarrays for antibodies such as IgG and IgM for virological detection using surface acoustic wave (SAW) detectors Serological detectors, as well as RT-PCR assays for nucleic acid targets using fluorescent detectors, are designated by Autonomous Medical Devices Inc. as detectors A10, A20, and A30 CD, respectively. The unit and its corresponding CD are measuring or assaying devices that do not perform high-level diagnostic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com