Harvesting and piling-up machine of Saccharum officinarum

A sugarcane and sugarcane delivery technology is applied in the field of agricultural machinery and equipment to achieve the effects of ingenious structural design, stable clamping and conveying, and improved transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings. In the description of the present invention, the orientation words of "front", "rear", "left" and "right" are defined based on the perspective of the driver of the sugarcane harvester.

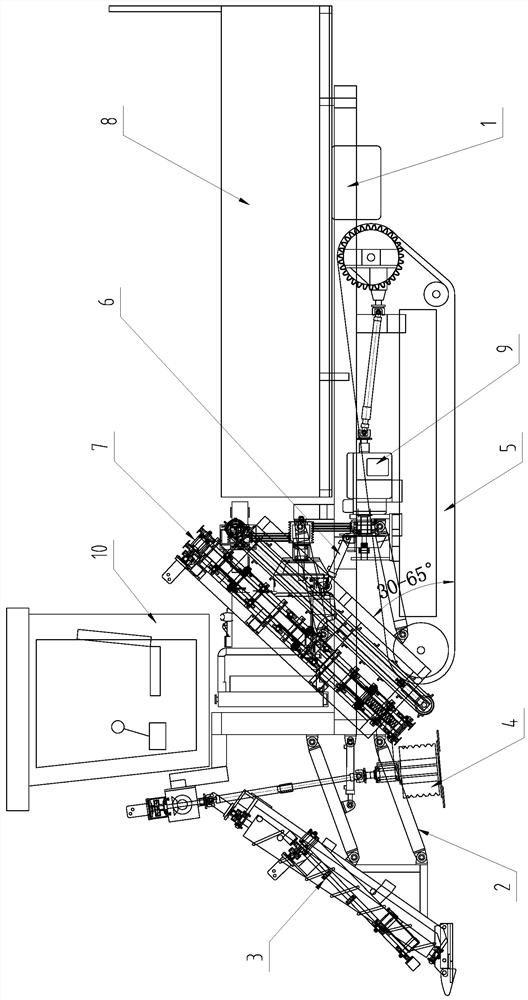

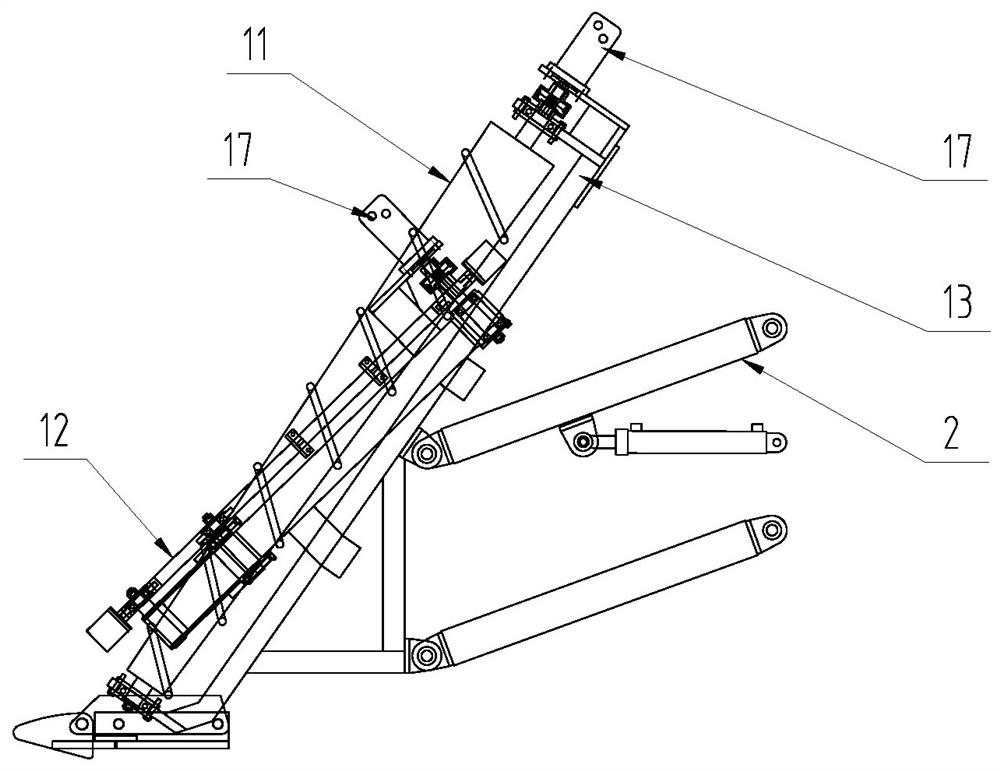

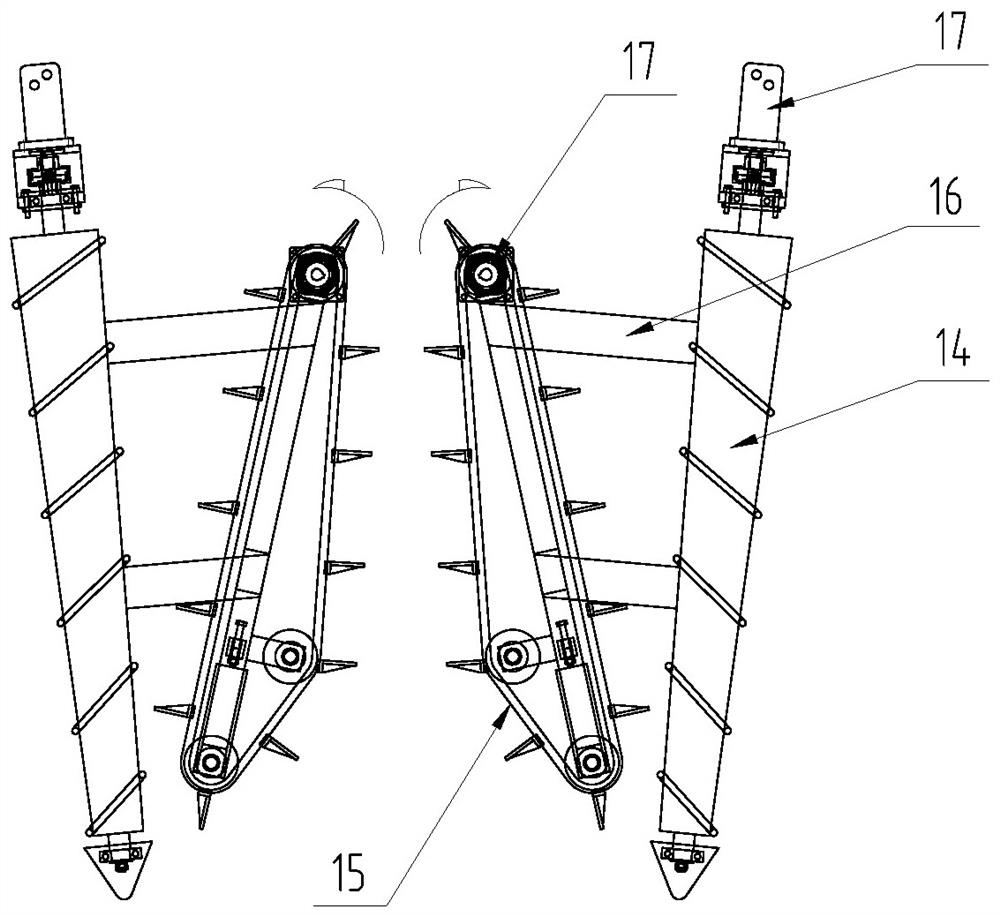

[0044] Such as Figure 1-2 As shown, the sugarcane mower is provided with a vehicle frame 1, and the front end of the vehicle frame 1 is provided with a cane-holding cane-holding mechanism 3 with a low front and a rear-high inclination through the first hydraulic lifting arm assembly 2. A cutter head mechanism 4 is provided at the rear of the vehicle frame 1, a crawler chassis 5 is provided under the middle part of the vehicle frame 1, and a front low rear high The cane-sending mechanism 7 that is arranged obliquely, and the front-end entrance of the cane-sending mechanism 7 is positioned at the right rear of the cutter head mechanism 4, the middle and rear part of the vehicle frame 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com