Heat energy recovery device of customized tail gas system

A heat recovery and tail gas technology, applied in lighting and heating equipment, chemical instruments and methods, combustion product treatment, etc., can solve problems such as energy loss, heat waste, environmental pollution, etc., and achieve fast settlement and long settlement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

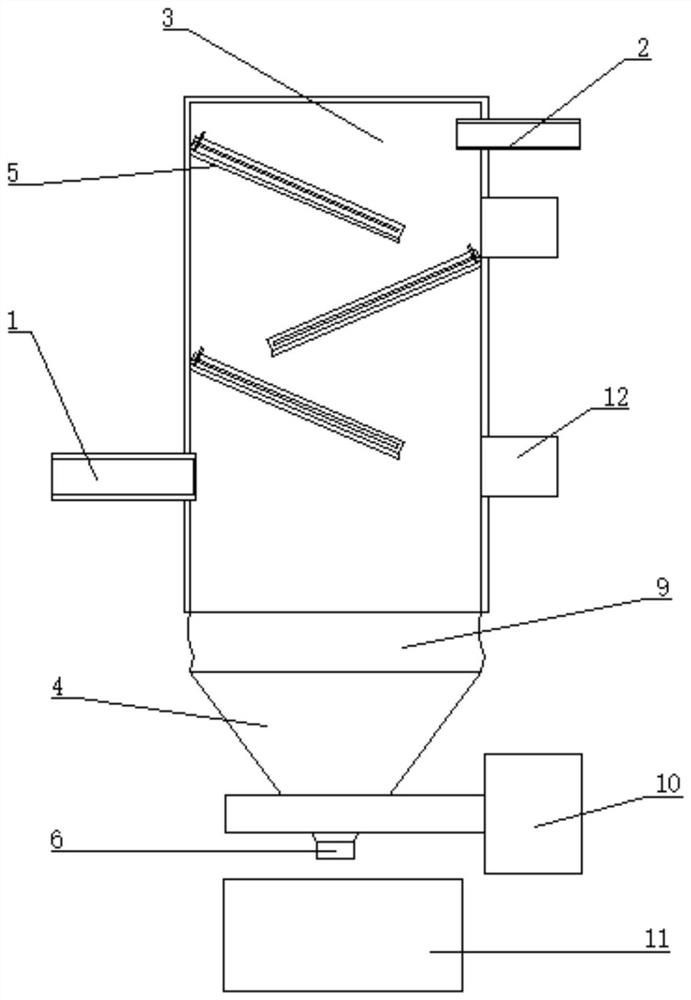

[0023] Such as figure 1 and 2 As shown, the present invention provides a heat recovery device for a customized tail gas system, including a tail gas settling mechanism, and the tail gas settling mechanism includes an inlet pipe 1, an outlet pipe 2, and a square settling tank 3;

[0024] The square settling tank 3 includes a correspondingly connected tank top plate, a tank front plate, a tank rear plate, two tank side plates and a tank bottom bucket 4;

[0025] The middle part of one tank side plate is provided with an air inlet hole, and the top of the other tank side plate is provided with an air outlet hole, the air inlet pipe 1 is connected to the outside of the air inlet hole, and the air outlet pipe 2 is connected to the air outlet hole;

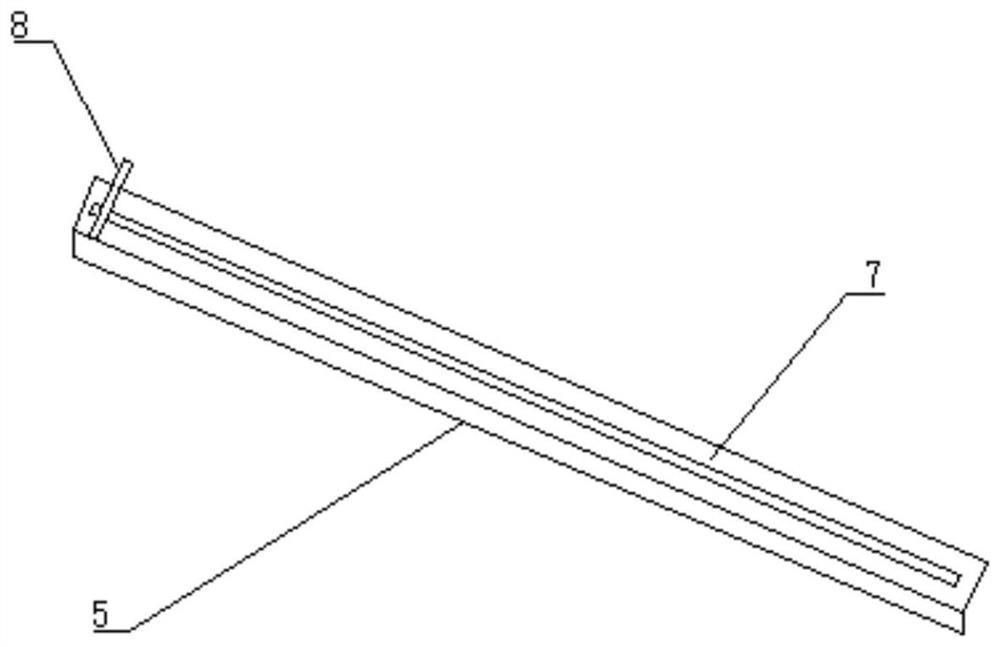

[0026] Several inclined baffles 5 are arranged in the square settling tank 3, and the two sides of the inclined ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap