Multi-connecting-rod balance lifting mechanism for automobile chassis assembling

A technology for an automobile chassis and a lifting mechanism, which is applied to the traveling mechanism, the spring mechanism, the lifting frame, etc., can solve the problems of inability to meet the teaching use, and the lifting of the automobile frame is easy to cause shaking, etc., and achieves simple structure and low manufacturing cost. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

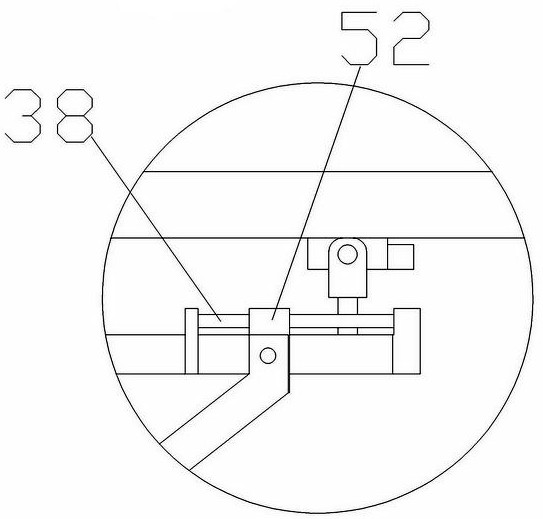

[0018] Referring to the drawings, an automotive chassis assembly is equipped with a multi-link balanced mechanism, including rail 1 and guide plate 2, orbit 1, and guide plates 2, and the top of the rail 1, and the guide plate 2. The liter 3 slides on the track 1 and can be moved on the track 1 under the motor drive;

[0019] The lifting device 3 includes an upper frame 30, and an auxiliary rotary wheel 31 is provided in the upper side edge of the upper frame 30, and the auxiliary rotary wheel 31 is rolled with the guide plate 2, and the upper frame 30 is provided with a walking bracket 32, and there are more travel brackets 32. The row wheel 33, the travel wheel 33 rolling is connected to the inside of the ingredient track 1, the traveling motor 34 is fixed to the traveling bracket 32, and the traveling motor 34 rotor is fixed to the travel wheel 33 shaft and drive the row wheel 33 to rotate Walking on the track 1, hinges the first end of the first link 35 in the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com