Purification and regeneration method of waste organic alkali

An organic base and organic membrane technology, which is applied in the field of purification and regeneration of waste organic base, can solve the problems of high wastewater treatment cost, environmental hazards, and large waste, and achieve the effects of reducing disposal costs and environmental risks, reducing waste, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

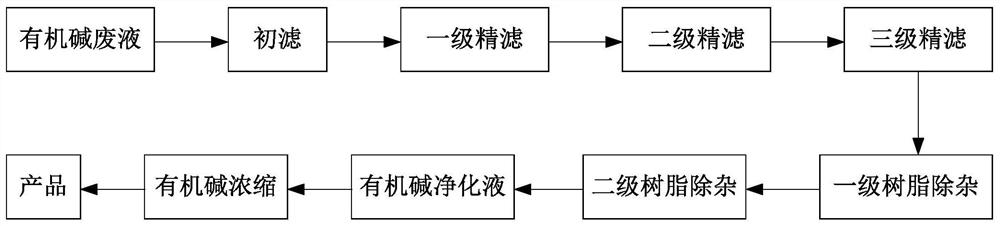

[0019] Such as figure 1 Shown, a kind of purification regeneration method of waste organic base comprises the steps:

[0020] 1) Pump the organic alkali waste liquid into the filter element and filter bag with a precision of 0.1um ~ 10um, initially filter the large particles of impurities, and then add it to the circulation storage tank of the purification device;

[0021] 2) Pump the raw material waste liquid into the membrane with a precision of 1-10nm through a high-pressure pump, perform a first-level fine filtration, and collect the feed liquid of the first-level fine filtration and put it into a buffer tank;

[0022] 3) Pump the primary fine filter material liquid into the membrane with a precision of <5nm through a high-pressure pump, perform secondary fine filtration, collect the secondary fine filter liquid and put it into a buffer tank;

[0023] 4) Pump the second-stage fine filter material liquid into the membrane with a precision <0.1nm through the high-pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com