A phosphorus-sulfur co-doped graphene supported mo 2 c Composite material preparation method

A composite material and co-doping technology, which is applied in the field of preparation of phosphorus-sulfur co-doped graphene-loaded Mo2C composite materials, can solve the problems of consuming large fossil energy and achieve improved catalytic activity and stability, good electrocatalytic performance, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

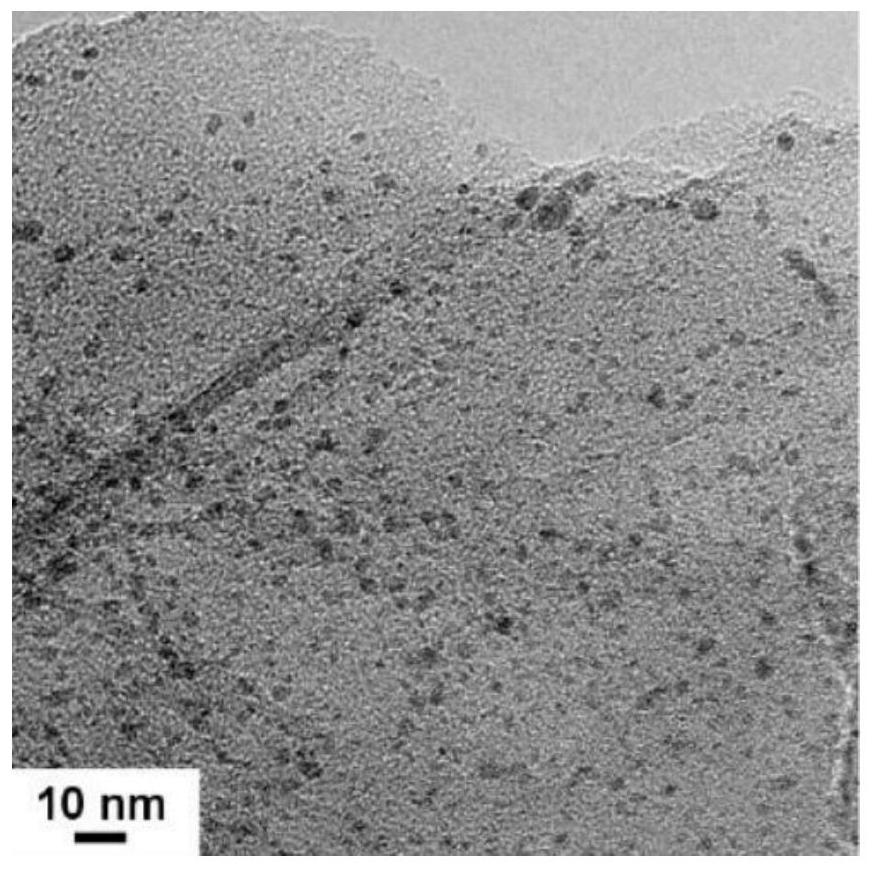

[0023] A phosphorus-sulfur co-doped graphene supported Mo 2 C composite material, preparation method comprises the following steps:

[0024] (1) Add 100mg graphene oxide into 150ml deionized water, ultrasonically disperse for 1h, add 150μl phosphoric acid, ultrasonically mix for 8h until uniform, then pour the mixed sample into a watch glass, dry at 85°C for 12h, and then transfer to a muffle furnace In the process, the temperature was raised to 800°C at a rate of 5°C / min, and calcined for 3h;

[0025] (2) Add the product of step (1) into 200ml of deionized water, ultrasonically disperse for 1h, add 150μl of sulfuric acid, ultrasonically mix for 2h until uniform, freeze-dry, then heat up to 1000°C at a rate of 5°C / min, and calcined for 2h to obtain Phosphorus and sulfur co-doped graphene supported Mo 2 C material.

[0026] (3) Add the product of step (2) into deionized water, ultrasonicate for 45min, add 300mg of ammonium molybdate tetrahydrate into 20ml of deionized water,...

Embodiment 2

[0028] A phosphorus-sulfur co-doped graphene supported Mo 2 C composite material, preparation method comprises the following steps:

[0029] (1) Add 100mg graphene oxide to 150ml deionized water, ultrasonically disperse for 1h, add 100μl phosphoric acid, ultrasonically mix for 8h until uniform, then pour the mixed sample into a watch glass, dry at 85°C for 12h, and then transfer to a muffle furnace In the process, the temperature was raised to 700°C at a rate of 2°C / min, and calcined for 2h;

[0030] (2) Add the product of step (1) into 200ml of deionized water, ultrasonically disperse for 1h, add 100μl of sulfuric acid, ultrasonically mix for 2h until uniform, freeze-dry, then heat up to 800°C at a rate of 2°C / min, and calcined for 1h to obtain Phosphorus and sulfur co-doped graphene supported Mo 2 C material.

[0031] (3) Add the product of step (2) into deionized water, ultrasonicate for 30min, add 200mg of ammonium molybdate tetrahydrate into 20ml of deionized water, st...

Embodiment 3

[0033] A phosphorus-sulfur co-doped graphene supported Mo 2 C composite material, preparation method comprises the following steps:

[0034] (1) Add 100mg graphene oxide into 150ml deionized water, ultrasonically disperse for 1h, add 150μl phosphoric acid, ultrasonically mix for 8h until uniform, then pour the mixed sample into a watch glass, dry at 85°C for 12h, and then transfer to a muffle furnace In the process, the temperature was raised to 900°C at a rate of 8°C / min, and calcined for 4h;

[0035] (2) Add the product of step (1) into 200ml deionized water, ultrasonically disperse for 1h, add 150μl of sulfuric acid, ultrasonically mix for 2h until uniform, freeze-dry, then heat up to 1200°C at a rate of 8°C / min, and calcined for 3h to obtain Phosphorus-sulfur co-doped graphene supported Mo2C material.

[0036] (3) Add the product of step (2) into deionized water, ultrasonicate for 60min, add 400mg of ammonium molybdate tetrahydrate into 20ml of deionized water, stir to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com