Loosening and refining device for cloth pretreatment

A refining device and cloth technology, applied in the processing of textile materials, equipment configuration for processing textile materials, spraying/spraying of textile materials, etc., can solve problems such as maintaining temperature, and achieve the effect of preventing excessive drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

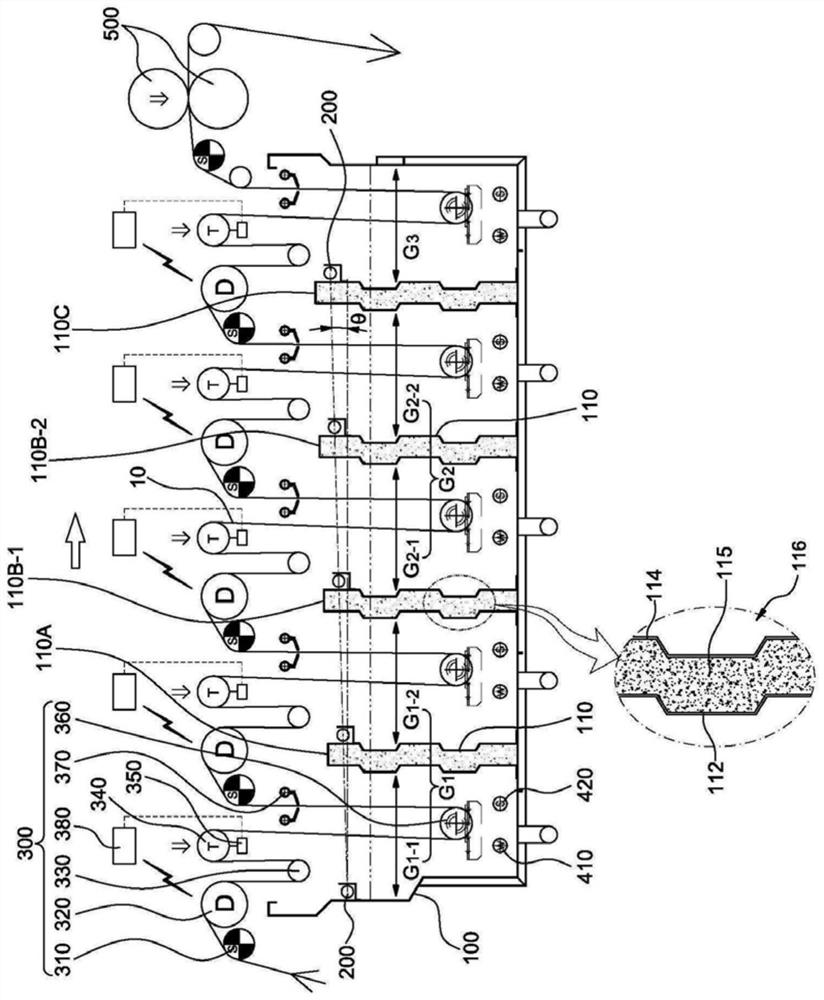

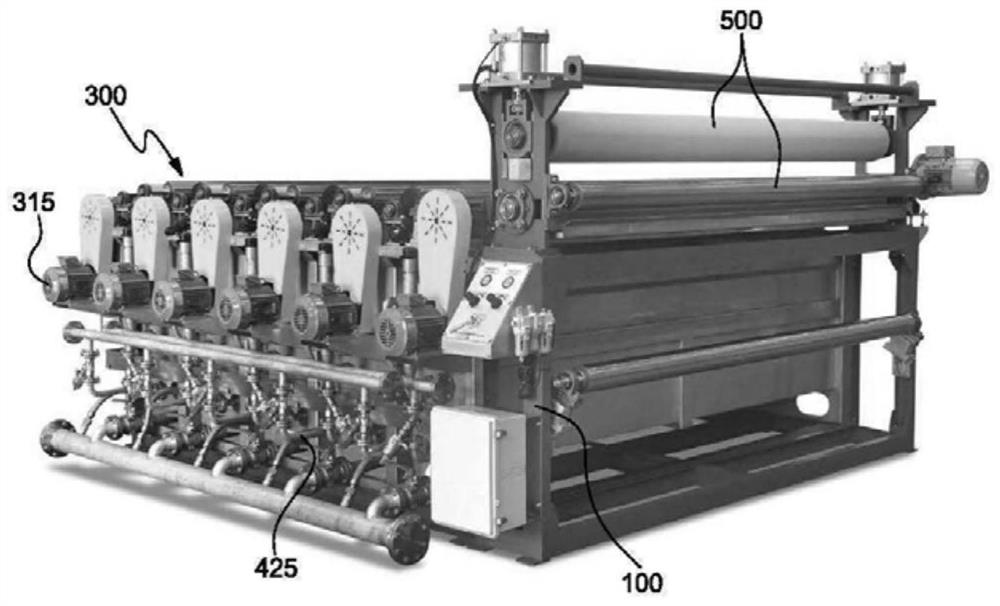

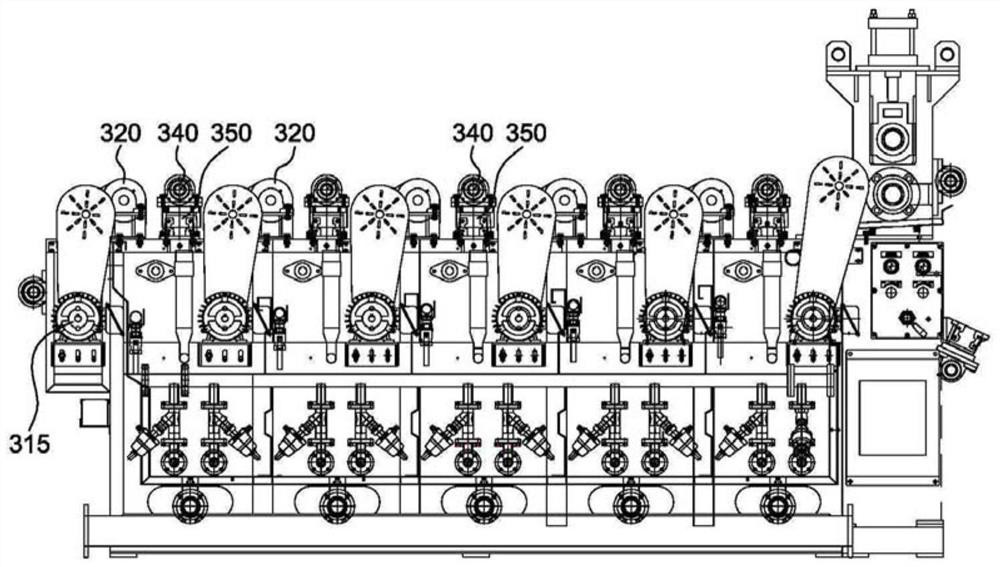

[0064] The loosening and refining device applicable to the cloth pretreatment of the present invention, such as Figure 1 to Figure 6 As shown, it includes: a casing 100, which is filled with washing water and chemicals inside, preheats the washing water by means of steam heating, and is divided into first partitions with different temperatures of the washing water by the first partition wall 110A. , the preheating section G1 of the second preheating section G1-1, G1-2, and the above-mentioned preheating section G1 are divided by the second partition wall 110B-1, in order to heat the cloth 10 passing through the above-mentioned preheating section G1 The heating zone G2, which is divided into the first and second heating zones G2-1 and G2-2 by the second partition wall 110B-2, is divided from the above-mentioned heating zone G2 by the third partition wall 110C, and is used to divide the above-mentioned heating zone The cooling section G3 in which the cloth 10 of G2 is cooled is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com