Low-nitrogen environment-friendly circulating fluidized bed hot water boiler

A circulating fluidized bed and hot water boiler technology, which is applied to fluidized bed combustion equipment, fluid heaters, water heaters, etc., can solve the problems of high energy consumption, low separation efficiency, and high NOx emissions, and improve separation efficiency , Improve heat transfer effect, reduce the effect of NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

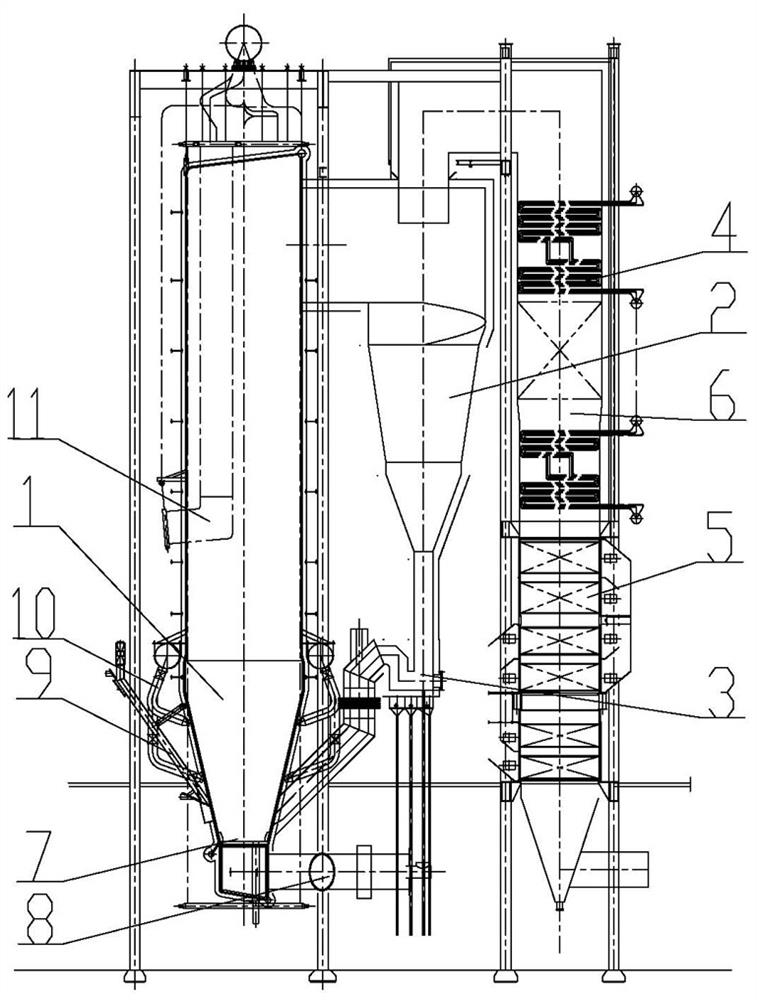

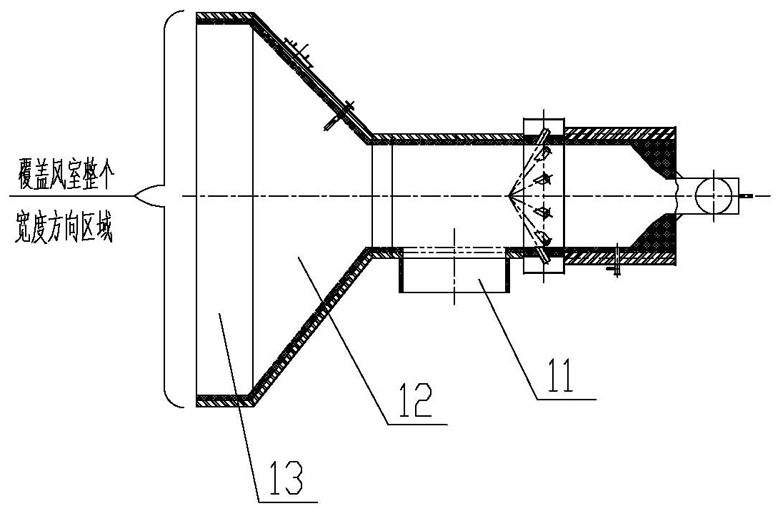

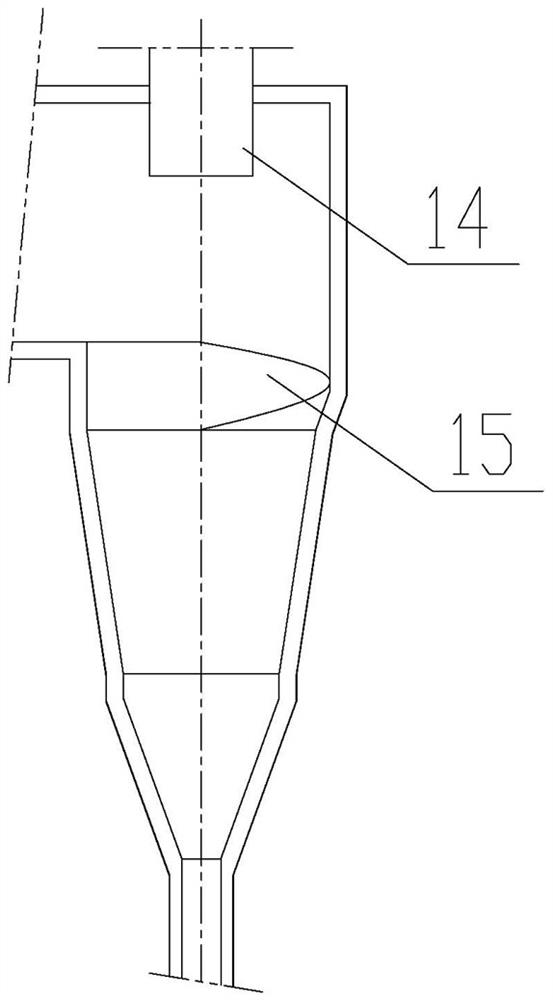

[0017] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a low-nitrogen environment-friendly circulating fluidized bed hot water boiler includes a furnace 1, a separator 2, and a tail flue 6. The bottom of the separator 2 is provided with a return device 4 connected to the furnace 1, and the return device 4 is arranged The three air chambers are respectively connected with the loosening wind, conveying wind and material returning air, which play the role of loosening, conveying and material returning in sequence. The material returning air cap and the connecting pipe in the material returning device are welded to avoid the head of the air cap falling off during operation. A coal feeding device is provided on the hearth that causes poor material return. The bottom of the furnace 1 is provided with an air distribution plate 7 and an ignition device 8 , an economizer 4 and an air preheater 5 are installed in the tail flue 6 , a primary hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com