A test system and test method for motion response test of a deep-sea operating platform

A motion response, working platform technology, applied in fluid dynamics test, machine/structural component testing, measuring device, etc., can solve the problems of poor real-time data acquisition, high test model requirements, high test cost, etc., to reduce design The effect of difficulty and test cost, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

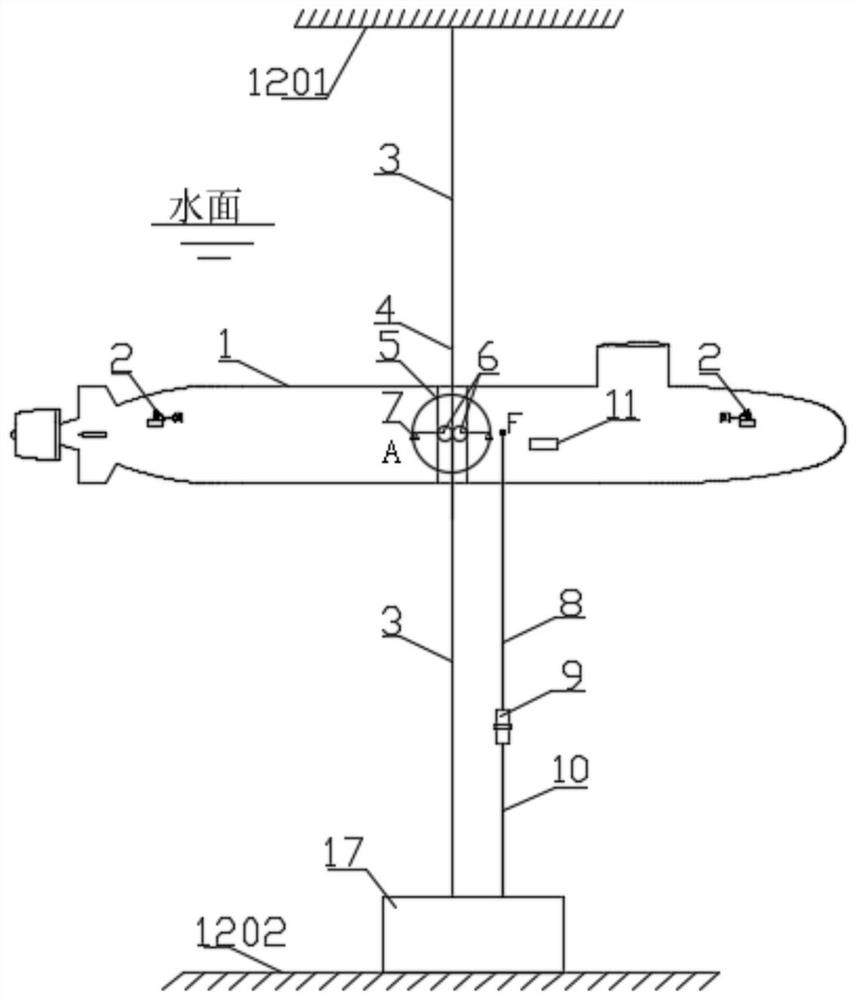

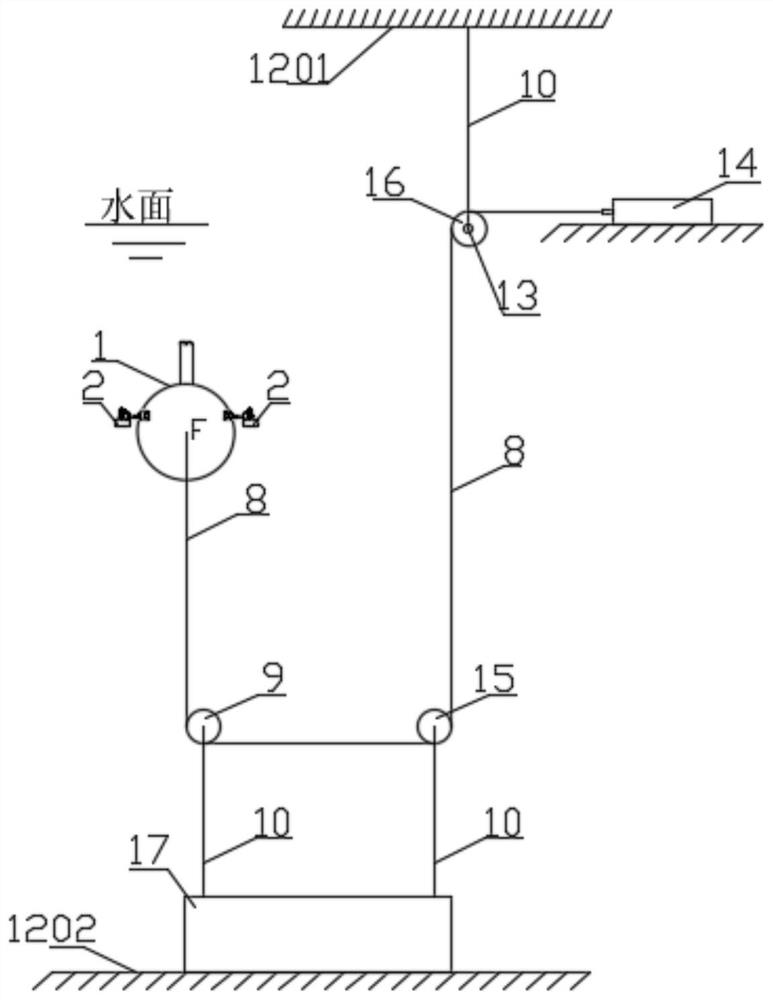

[0039] Such as Figure 1-Figure 3 As shown, the deep-sea operation platform motion response test system of this embodiment includes an upper wall 1201 above the water surface and a lower wall 1202 below the water surface,

[0040] The lower wall 1202 is provided with a weight 17,

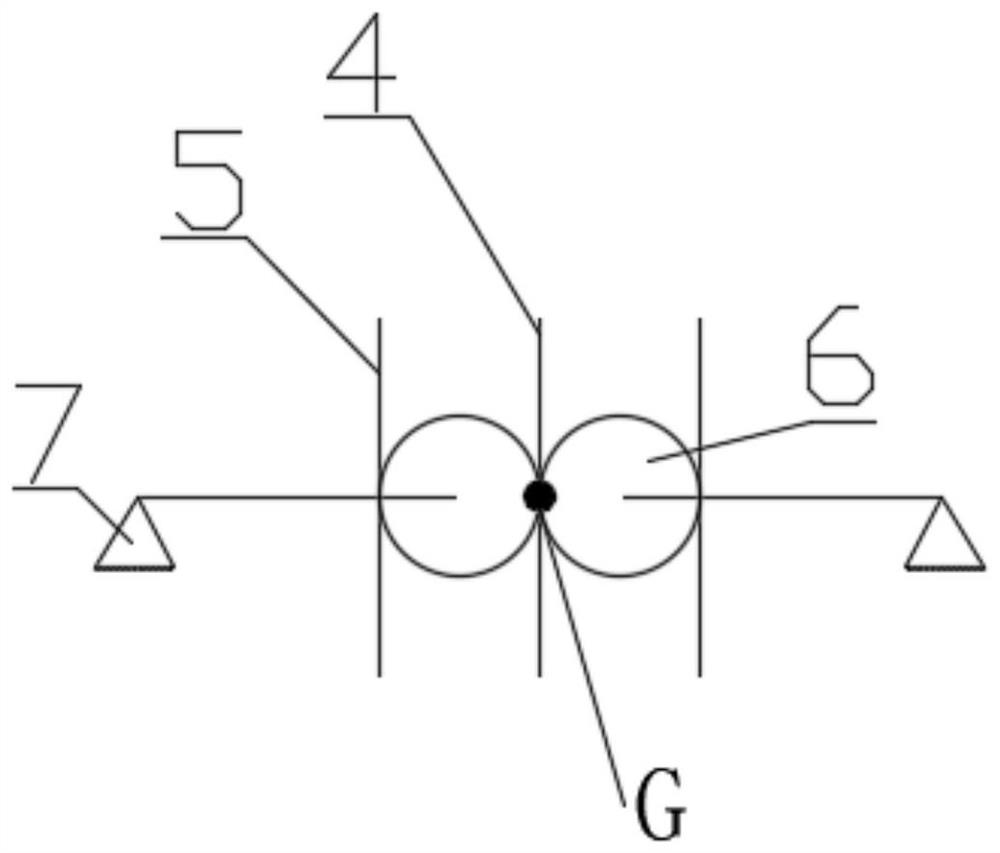

[0041] Also includes the underwater platform test model 1, the underwater platform test model 1 is equipped with a plurality of auxiliary thrusters 2, the interior of the underwater platform test model 1 is provided with an inclinometer 11, and the middle part of the underwater platform test model 1 is provided with a The underwater platform test model 1 at the hole 5 and the through hole 5 are symmetrically provided with support seats 7, and the inner sides of the two support seats 7 are equipped with rollers 6 through connecting rods, and the two rollers 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com