Aluminum profile defect detection method

A defect detection and aluminum profile technology, applied in neural learning methods, biological neural network models, image data processing, etc., can solve the problems of inability to generalize aluminum profiles, poor generalization effect of defects, etc., achieve accurate regression positioning, and enhance generalization. high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

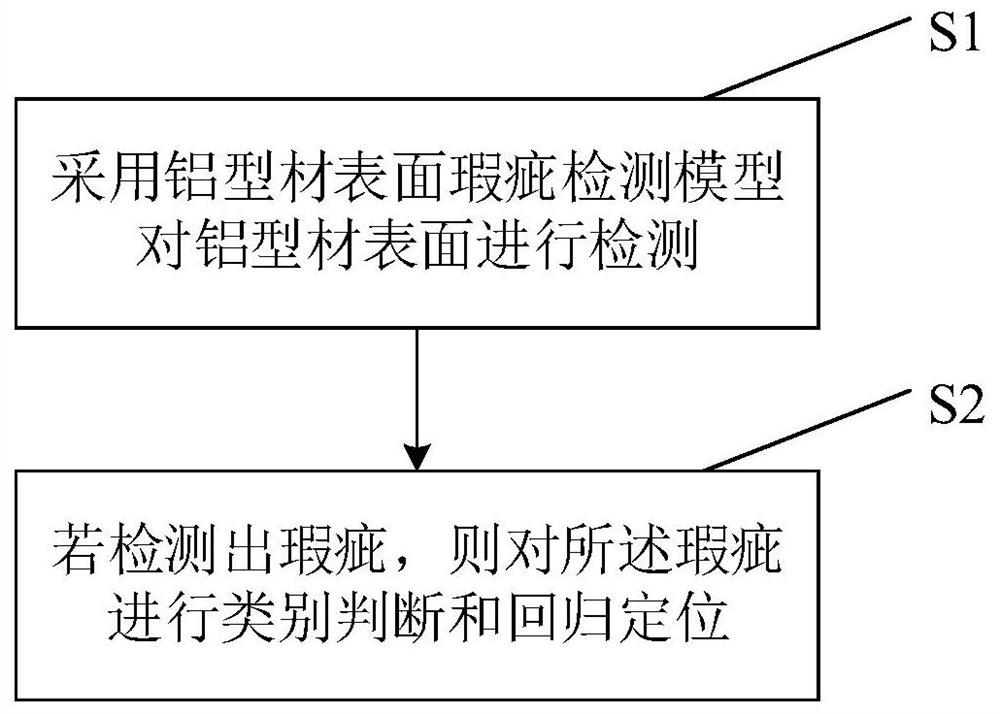

[0056] Embodiments of the present invention provide a method for detecting defects in aluminum profiles, such as figure 1 shown, including:

[0057] Step 1, use the aluminum profile surface defect detection model to detect the surface of the aluminum profile.

[0058] Step 2: If a defect is detected, category judgment and regression positioning are performed on the defect.

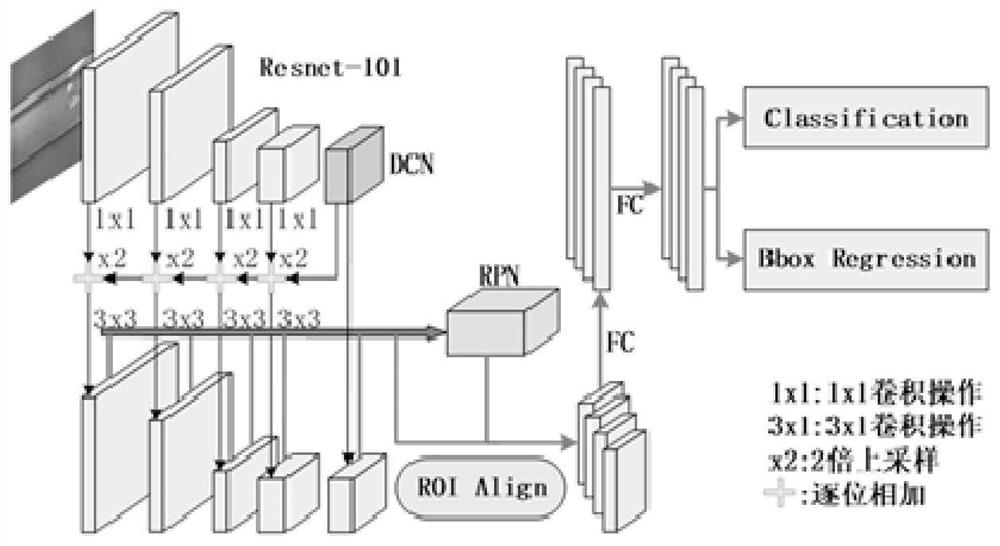

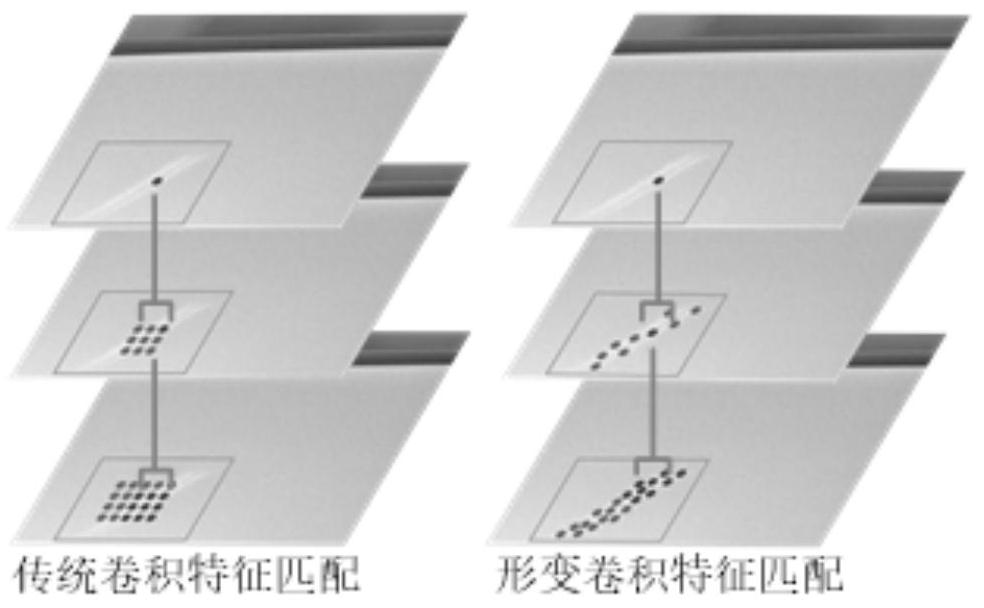

[0059] Among them, the aluminum profile surface defect detection model uses Resnet-101 as the backbone network; the aluminum profile surface defect detection model adopts the feature pyramid network and deformation convolution algorithm for targeted detection of irregular defects on the aluminum profile surface; The defect detection model uses the region of interest stacking (ROI Align) extraction feature map algorithm and the improved candidate frame generation network loss function to locate small defects.

[0060] In this embodiment, the aluminum profile surface defect detection model adopts Resnet-10...

Embodiment 2

[0105] The environment used for the detection model training in this embodiment is configured as Intel i7-9700K processor, 64GB memory, two NVIDIA GeForce RTX 2080Ti graphics cards, the used deep learning framework is Pytorch, the value is 0.5, and the training epochs is 100. During the training process The accuracy curve (Accuracy) and the loss curve (LOSS) such as Image 6 shown. After the model is trained, some detection effects on the test set are as follows: Figure 7 shown.

[0106] In order to test the ability of the improved model in this paper to detect and identify different types of defects in aluminum profiles, firstly, 10 types of defects in aluminum profiles, such as dirty spots, bumps, and pits, were selected for verification. The results are shown in Table 1.

[0107] Table 1 Model performance of different defect types

[0108]

[0109] By analyzing the data in the table, it can be concluded that the detection of different types of defects has high accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com