Intelligent scheduling and tracing system and method for power battery formation process

A technology of intelligent dispatching and power batteries, which is applied in the direction of secondary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc., can solve the problems of increased battery performance, increased labor costs of enterprises, and low consistency, and achieves the goal of ensuring control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

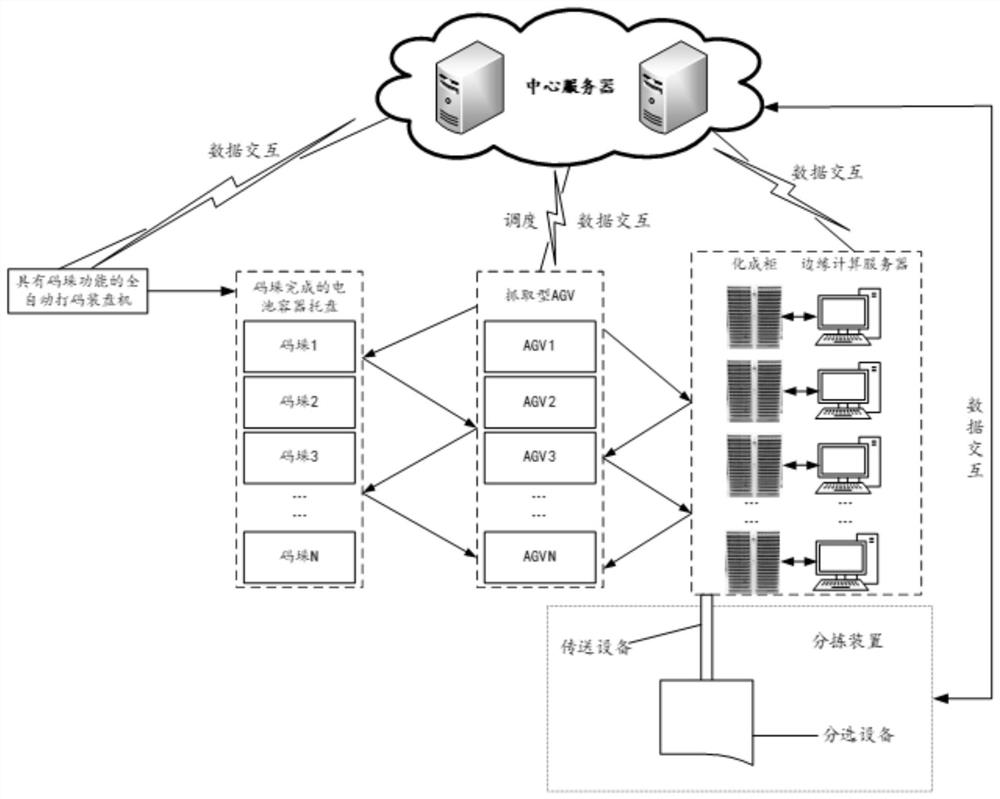

[0038] Such as figure 1 As shown, the power battery formation process intelligent dispatching and traceability system of this embodiment mainly includes battery container trays (also referred to as "container trays" or "battery trays", which will not be described in detail later), automatic coding and loading machines, grabbing Type AGV, chemical control cabinet, edge computing server, sorting device, and central server.

[0039] The battery container tray can adopt a three-dimensional structure with a square cross-section made of hard plastic, and the interior is divided into 10*10 matrix cells. Each cell is used to place a single battery, and the inside of the cell contains a slot structure. , used to fix the single battery. Optionally, in this embodiment, a low-frequency RFID tag is pasted on the side surface of the battery container tray for information identification of the battery container tray. Optionally, guide rail grooves are provided on both sides of each contain...

Embodiment 2

[0055] Corresponding to the above-mentioned system, this embodiment discloses a method for intelligent scheduling and traceability of a power battery formation process. The method includes the following steps:

[0056] (1) The coding control system associates the coding information of each group of batteries with the location information (A1-J10) of the battery container tray and the ID of the battery container tray.

[0057] (2) Upload and store the associated information in step (1) to the central server.

[0058] (3) At the beginning stage of forming into capacity, the edge computing server control program reads the ID of the battery container tray in each card slot through the RFID reader, and compares the time series data in the process of forming into capacity with each battery container tray ID in the corresponding container tray. location (A1-J10), stored locally in the form of a file, and uploaded to the central server after the completion of the content.

[0059] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com