Novel bonding structure surface acoustic wave device and preparation method thereof

A surface acoustic wave device and bonding structure technology, applied in electrical components, impedance networks and other directions, can solve the problems of unsatisfactory bonding interface quality, device Q value decline, device performance deterioration, etc., to improve withstand power, The effect of improving quality and suppressing parasitic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

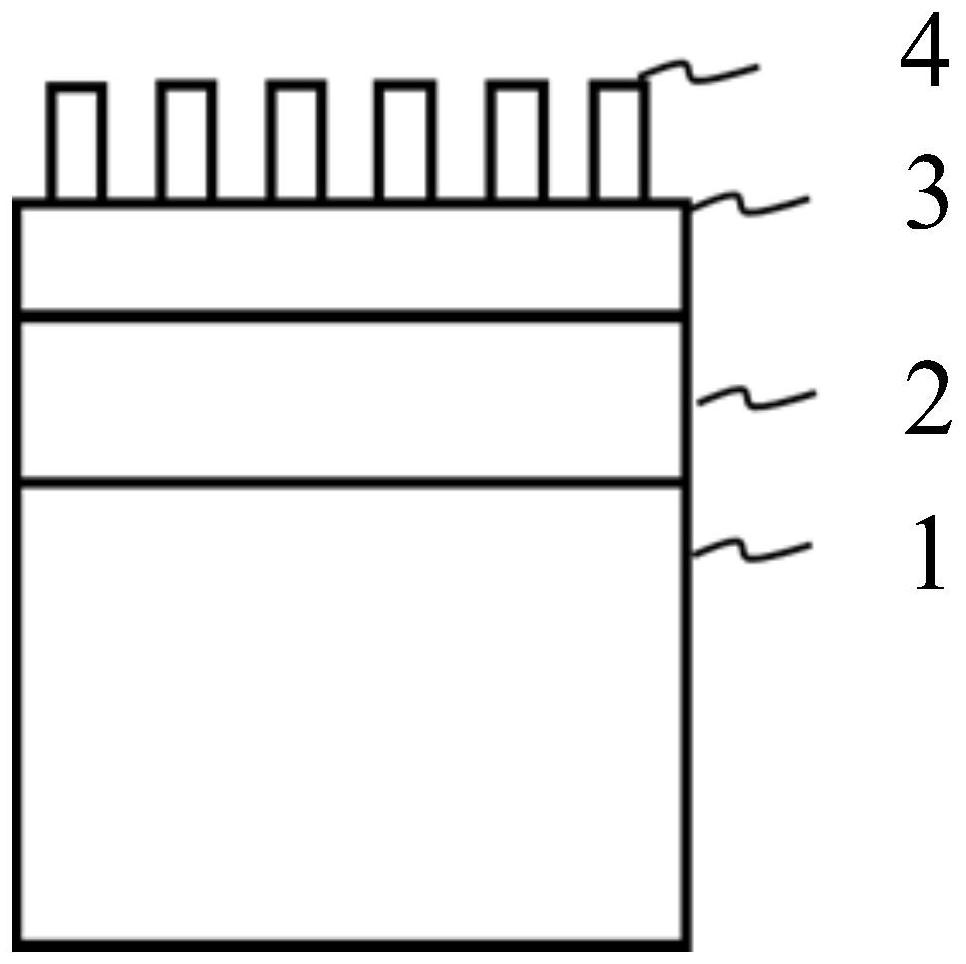

[0037] A new bonded structure surface acoustic wave device, the schematic diagram of its structure is shown in figure 1 As shown, it includes a support substrate 1, a composition graded layer 2, a piezoelectric substrate 3, and an interdigital transducer 4 from bottom to top. The composition graded layer 2 is used to provide total reflection of sound waves, and the composition graded layer 2 is close to The sound velocity of the components on the substrate side is higher than that on the side close to the piezoelectric substrate 3, and the components change linearly along the growth direction.

[0038] Specifically, the composition of the graded composition layer 2 near the substrate is Si 3 N 4 , the intermediate component is SiO x N 1-x , the composition near the piezoelectric substrate 3 side is SiO 2 , where 03 N 4 The sound velocity of the components is higher than that of SiO 2 The sound velocity of the component, the acoustic impedance of the acoustic wave of the ...

Embodiment 2

[0055] A new bonded structure surface acoustic wave device, the schematic diagram of its structure is shown in figure 1 As shown, it includes a support substrate 1, a composition graded layer 2, a piezoelectric substrate 3, and an interdigital transducer 4 from bottom to top. The composition graded layer 2 is used to provide total reflection of sound waves, and the composition graded layer 2 is close to The sound velocity of the components on the substrate side is higher than that on the side close to the piezoelectric substrate 3, and the components change linearly along the growth direction.

[0056] Specifically, the composition of the graded composition layer 2 near the substrate is AlN, and the middle composition is Al x Ga 1-x N. The component near the piezoelectric substrate 3 is GaN, where 0x Ga 1-x The Al composition of N gradually decreases linearly along the growth direction, the Ga composition gradually increases linearly along the growth direction, and Al x Ga ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com